Packaging Design

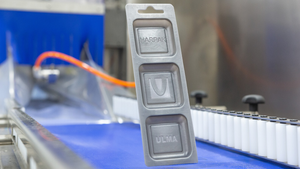

SnapSlide Rx closure

Pharmaceutical Packaging

Torque-Free Rx Closure Allows for Single-Handed OperationTorque-Free Rx Closure Allows for Single-Handed Operation

The child-resistant cap for amber vials features a two-step opening procedure for people with limited dexterity.

Sign up for the Packaging Digest News & Insights newsletter.