Automated Case Packer Can Increase Throughput, Reduce Labor

A new robotic top-load case packer can pick and place up to 20 cases per minute.

September 21, 2021

Providers of consumer and commercial packaged goods looking to automate their packaging process can turn to a new top-load case packer.

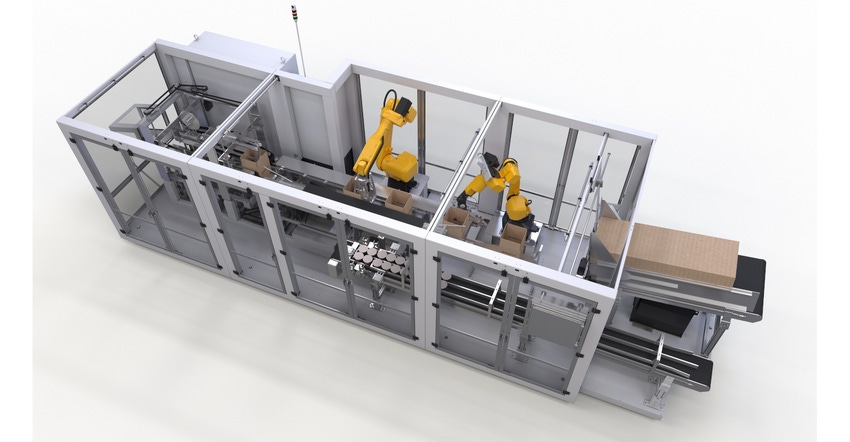

The RT1000, from Alexandria, MN-based Brenton, offers a pick-and-place rate of up to 20 cases per minute, a maximum payload of 70 lbs., and the ability to load multiple cases at once. The machine also features a modular design, allowing customers to use their existing case erector and sealers or opt for an integrated case erector/sealer for either tape or glue applications.

A simple human-machine interface enables programming by staff with varying levels of expertise. Other benefits include easy transport and setup, standardized main design, customizable infeed, mechanical automatic changeover, remote connectivity, and optional remote support capability.

The RT1000 is suited for applications in the consumer and commercial packaged food, household chemical, and personal care sectors. It offers the most value for customers seeing increased demand and those seeking to add products or pack patterns within a defined range without changeover parts, according to the company. The machine is available with a short lead time and is priced competitively.

Brenton will be exhibiting this new product at Pack Expo Las Vegas 2021 (Las Vegas; September 27-29), Booth C-3225.

About the Author(s)

You May Also Like