Automatic guided vehicles make beverage producer more efficient

|

|

Unique, new automatic guided vehicles (AGVs) with advanced-automation features are having a major impact at a new distribution center built by a major carbonated-beverages producer in the southeastern part of the U.S. The center incorporates a dynamic new line of AGVs from America in Motion Inc. (AIM) that are actually automatic guided carts (AGCs). The AGCs consist of a standard burden-carrier base with an adaptable top to which different load-handling devices, such as roller decks or lifting forks, can be added.

The AGCs have onboard battery systems that can power the cart for up to eight hours and, with opportunity charging, can fully recharge in as little as five minutes. The AGC system also features RFID technology onboard.

However, the newest significant concepts from AIM are complete control systems from Beckhoff Automation, LLC. “The new AGCs are easier for end users to integrate and cost about half as much as traditional AGVs, making the technology attainable for far more applications than previously possible,” says Tommy Hessler, CEO of America in Motion. “It's quite easy to add or remove capacity based on the type of load the AGC must handle due to the modular structure of the Beckhoff controls.

“We looked into some other manufacturers, but we selected the AIM AGCs because AIM listened to our requirements and designed a system around them, instead of trying to sell standard products and workarounds that met our needs halfway. AIM also helped us develop true solutions, not just simple products,” says the beverage company's project manager Derek Clever. “The beverage industry continues to grow in complexity with proliferation of new categories and multiple SKUs. This impacts the overall capacity, increases the strain on the logistics network and represents a constant struggle to contain costs. AIM's system capabilities address each one of these challenges and increases productivity, consistency and velocity while reducing complexity.”

Integrated intelligence

“The Beckhoff controls have allowed AIM to integrate intelligence into the vehicle,” notes Theresa Blasius, vp of engineering at AIM. “Our AGCs can be best utilized in applications that already have some automation control, such as robot cells or automatic conveyor systems with a PLC. Via OPC (open connectivity via open standards), these types of controllers can easily command our AGC to carry the load anywhere in the facility.

|

|

“The AIM system improves quality, reliability and efficiency by automating the repetitive and labor-intensive order-building process, which virtually eliminates human picking errors,” says Clever. “Also, the system's productivity can increase capacity as the business grows, with minimal additions to financial or human capital. The Beckhoff components were key components adding to the flexibility of the AIM system.”

Voice-activated commands

“We considered a non-PC-based approach, but decided against it, since we needed the ability to run our C# programs onboard, and we decided to make full use of the features that Windows CE offers for our applications,” Hessler adds. “This way, we can integrate voice-activated commands, which is much easier with the open Beckhoff system than with our competitors' closed alternatives.”

The new AGCs are designed to fully utilize Beckhoff products that are based on familiar off-the-shelf technologies for leading-edge performance with user-friendly controls. “No closed, proprietary controls are found in any of our AGCs,” Hessler says. “We want our customers to have the ability to easily handle AGC maintenance if desired.” AIM uses the Beckhoff CP7202 panel PC with its 15-in. touchscreen as an all-in-one system controller and user interface.

Installed in a central location as a fixed AGC operator station, the CP7202 handles a broad range of functionality, including routing and traffic management, overall system logic for the AGCs and I/O data from stationary devices, such as the AGC battery chargers, load stands or other machinery. Other functions include traffic management, vehicle-selection optimization, vehicle-task management, load tracking, path-programming logic and AGC fault finding and diagnostics.

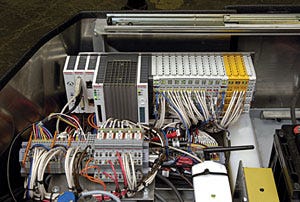

Onboard, the AGCs are equipped with CX1010 embedded PCs, which function as programmable-automation controllers. The CX1010 devices are directly connected to Beckhoff bus-terminal I/O modules and TwinSAFE terminals for streamlined implementation of safety devices on the AGCs. TwinSAFE terminals do not require a dedicated safety PLC, which greatly reduces hard wiring of safety devices, can communicate over multiple, standard field buses and can be used alongside regular bus-terminal I/O with almost no restrictions.

AIM also installs distributed Beckhoff I/O near the panel PC stations and utilizes wireless local area network (WLAN) communication between the panel PC and the CX1010 onboard the AGCs.

Multiple PCs

“The CX1010 with a 500 megahertz Pentium® MMX (single instruction set)-compatible processor is our standard AGC controller, but we sometimes use the one gigahertz CX1020, when more central-processing unit horsepower is required, such as for weighing and scanning of products,” Hessler says. “It's quite helpful that the CX family of PCs can scale up in power whenever a processing boost is needed.”

The onboard CX1010 embedded PC handles all internal functions required for the AGC to operate, partly using TwinCAT PLC software from Beckhoff and partly through C# software developed by AIM.

The major functions are guidance (magnetic tape or wire), routing via RFID, charging, steering control, drive control and precision stop, manual control via pendant, automatic load handling and safety devices that are managed by TwinSAFE.

“TwinSAFE technology helps AIM maintain a competitive advantage by easily and cost-effectively integrating emergency stops and bumper stops into the AGCs,” Blasius says. “We completely adhere to global safety standards and can include features that our competitors can't yet touch. Traditional safety methods are far more complicated and expensive; so much so that some of our competitors forego comparable safety functions entirely.”

AIM also uses OPC for communication between its AGC system and other PLC-controlled equipment, such as conveyor systems and robotic controllers. A TwinCAT OPC server helps AIM easily integrate its AGC systems with other material-handling products, while facilitating streamlined system communications.

Short commissioning time

Throughout the project, AIM worked extensively with Beckhoff technical support in the U.S. headquarters, as well as Beckhoff's Windows CE development team in Verl, Germany. “Beckhoff technical support was instrumental to our success, with rapid resolution of technical questions,” Hessler says.

“The new AGCs containing the complete Beckhoff control system have run flawlessly in production mode,” Hessler continues. “With our new design running in the field since August 2008, we have determined that AGC reliability has been superb and system uptime has been maximized for our customers.”

Commissioning of a traditional AGV, including installation, testing and acceptance, is typically a two- or three-week project. “AIM successfully completed the commissioning of the new Beckhoff-controlled AGC in only

|

|

four days,” Hessler says.

Another tangible difference is with the programming. “Utilizing the Beckhoff embedded PC with Windows CE environment, AIM has been able to quickly integrate with our other equipment to create the total solution. This system is the perfect merger of reliable PLC control with IPC (Assn. Connecting Electronics Industries) sophistication,” Blasius says. “We have also implemented remote access for customer service and support using the CP7202. This saves AIM a great amount of engineering time and expense that would otherwise be spent for onsite-support visits.”

AIM intends to continue moving AGV technology forward using PC-based and industrial Ethernet technologies. “To serve our customers even better, we plan to implement EtherCAT I/O terminals and expanded WLAN capabilities,” Blasius says. “We don't think there are any serious alternatives to Beckhoff, considering the available tools from Windows CE to .NET framework to the open PC-based architectures.”

Adds Clever, “The AIM system has the capability to produce orders in real time, identifying each case on every pallet and generating advanced shipping notices that lead to order visibility throughout the entire distribution system. This ultimately improves customer service. The system improves quality, reliability and efficiency by automating the repetitive and labor-intensive order-building process, which virtually eliminates human picking errors. Also, the system's productivity can increase capacity as the business grows, with minimal additions to financial or human capital.”

More information is available: |

America In Motion Inc., 704/246-3961. www.weareaim.com. |

Beckhoff Automation LLC, 952/890-0000. www.beckhoffautomation.com. |

About the Author(s)

You May Also Like