Hybrids on my mind

“A little bit of this and a little bit of that.” This song by Pandora keeps playing in my head.

Seems like a lot of people are mixing up their idea palettes to create the next masterpiece. Hybrids are popping up all over the place. It’s what Mintel calls “blurring categories,” and it’s something that consumers enjoy because it gives them a pleasant surprise. When it comes to category mash-ups, consumers are even starting shift into the “we now expect it” stage; and a brand’s packaging can help deliver that delight.

We’re seeing evidence of the success of hybrids in both packaging material and machinery developments, though. A search for “hybrid” on packagingdigest.com turns up more than 60 items in just the last couple years.

We’ve seen containers combine the best of rigid and flexible, like Seventh Generation’s new plastic-bag-in-paper-bottle for laundry detergent and the resealable Zipbox that continues to advance.

We’ve seen containers combine the best of rigid and flexible, like Seventh Generation’s new plastic-bag-in-paper-bottle for laundry detergent and the resealable Zipbox that continues to advance.

Package decorating has been turned up a notch or two in recent years, some of which can be attributed to a blending of various print technologies, like this Hapa H230 Hybrid printer which unites UV flexo and UV digital printing in one machine.

Different container-making processes are also being connected, as in this alloy bottle for Project Eviive that “marries the manufacturing speed and light weighting of standard (drawn & ironed) beverage can technology with the dynamic shaping technology originally available only with heavier walled extruded aluminum containers.” Or in this example of hybrid cushioning that differs from traditional void-fill pillows because it features multiple air chambers in a horizontal and vertical pattern instead of one large cell.

On the machinery side, mechantronics–which melds mechanical and electronic technologies–is finding new potential with packaging machine builders, as engineers play with “how much of this” and “where to put that” to boost functionality, flexibility and affordability. Like the new R-250 shrink labeler from PDC Intl. that effectively positions servos on a primarily mechanical machine.

Then we’ve got a whole bunch of packaging machinery companies integrating robots into hybrid systems, like Intelligrated’s Alvey 950 hybrid in-line palletizer that uses one or more robotic arms for pattern forming, making it suitable for handling small, finished-case sizes, multiple-product formats and complex patterns.

We’ve even got a case study in our upcoming April 2011 issue from Recochem, which tells how the company successfully implemented robotic technology that combines pick-and-pack with material handling all in one hybrid system. Stay tuned for that!

We’ve even got a case study in our upcoming April 2011 issue from Recochem, which tells how the company successfully implemented robotic technology that combines pick-and-pack with material handling all in one hybrid system. Stay tuned for that!

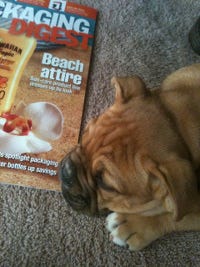

But the capper for writing about this now was a note yesterday from my associate publisher, Steve Everly, who introduced us to his new “assistant.” Adele Ophelia Everly, “Addy” for short, joined the PD team Wednesday, March 16, 2011. She’s 12 weeks young and, according to Steve, “She’s a new hybrid: Dogue de Bordeaux and English Bulldog. I’m in love.”

But the capper for writing about this now was a note yesterday from my associate publisher, Steve Everly, who introduced us to his new “assistant.” Adele Ophelia Everly, “Addy” for short, joined the PD team Wednesday, March 16, 2011. She’s 12 weeks young and, according to Steve, “She’s a new hybrid: Dogue de Bordeaux and English Bulldog. I’m in love.”

Can’t wait to see what other surprising mash-ups are in the works. What are you working on? Send me a note at [email protected] when you can.

Follow me on Twitter @lisajmpierce

About the Author(s)

You May Also Like