Software boosts efficiency at Amcor

|

The Amcor PET packaging plant in Blythewood,SC, produces more than 5 million plastic drinking bottles a day. |

“Downtime” may be the dirtiest word in the manufacturing industry. It refers to that worst-case scenario on the production line, when a piece of equipment is not functioning properly. The line is halted and if this condition isn't identified and corrected quickly enough, production targets are missed, customers become dissatisfied and money flies out the window.

The Amcor PET packaging plant in Blythewood, SC, produces more than 5 million plastic drinking bottles/day. With aggressive goals for efficiency, cost reduction and customer satisfaction, Amcor turned to Wonderware (www.wonderware.com), a business unit of Invensys Systems, Inc., for a plant-intelligence system that would provide the real-time information that enables managers to respond instantly to problems and keep Amcor's lines up and running.

“The big thing for us is that we are an incredibly lean manufacturing operation,” says Thom Iwancio, systems engineer at Amcor's Blythewood facility. Iwancio is responsible for managing the plant's information-technology requirements. “The typical operator runs three or four machines, and we don't have time to second-guess ourselves,” he says. “We need to find out what the issues are quickly and concisely, so we can address them.”

PET is one of the most common plastic-packaging material options for the beverage industry, and Amcor plays a big part in keeping popular beverages on store shelves by providing the plastic containers used to package these drinks. Through its 50 plants around the world, Amcor supplies PET containers to some of the world's largest makers of soft drinks, distilled water, juices, teas, sports drinks, dairy products, spirits and beer.

More than 45 different types of bottles for both hot and cold beverages are produced at the Blythewood plant, varying in colors, shapes and sizes, and including standard and customized designs. This makes the manufacturing environment highly complex and challenging to manage. When an extremely lean manufacturing approach is added to the mix, success depends on intelligence and speed. Questions for such success include “What is happening on the plant floor right now?” and “How quickly can you respond to problems that might interrupt the production line?”

Usability and effectiveness

|

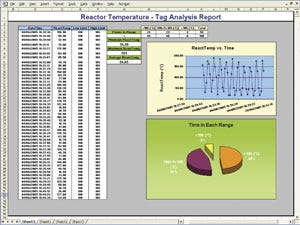

Trending, analysis and reporting software provides data-trend analysis, sophisticated numerical-data analysis and the capability to piblish real-time and historical planr information to the Web or to a company's intranet site. |

|

The Blythewood plant was built on a previously undeveloped site in 1998. This gave Amcor the advantage of being able to install brand new systems from scratch; Wonderware's InTouch software was an early choice for the facility's HMI requirements. Other systems were considered, but Wonderware's ease of use and effectiveness cinched its choice for the Blythewood facility.

“A lot of our selection decision was based on our confidence in Wonderware,” Iwancio says. “Industrial automation is Wonderware's core business. They don't do anything else, and with this kind of concentration, they have gotten very good at it.” Amcor's plant-intelligence requirements evolved over time, with the focus growing beyond process control and monitoring to encompass production-quality programs. To meet this new requirement, Iwancio has added and updated the plant-intelligence system's functionality, pioneering what has grown into a corporate-wide vision.

“The original installations were all strictly InTouch software to manage HMI,” Iwancio says. “As part of a corporate-wide, best-in-class initiative, management wanted to start recording key performance indicators, and we came up with a list of 10 for each basic process. We installed the Wonderware IndustrialSQL Server historian to manage that task. After a couple of years, Amcor decided it was time to monitor and evaluate downtime instances to assess how it was affecting the company's overall production.”

To achieve this, Amcor installed DT Analyst software, which is able to provide the necessary downtime evaluations. “We might have been able to do this without DT Analyst software, but the process would have been expensive, time-consuming and inefficient,” says Iwancio.

The PET bottle-manufacturing process starts with the raw material in the form of resin pellets. The pellets are fed into an injection-molding machine, where they are heated and shaped into preforms, which look like test tubes. The Blythewood plant makes millions of preforms each day, with many shipped to other plants that don't have their own injection-molding capability. Others are stored for later use. The Blythewood facility forms the remaining preforms into finished bottles, which are labeled, palletized and shipped to customers.

Tracks historical data

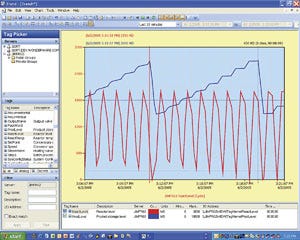

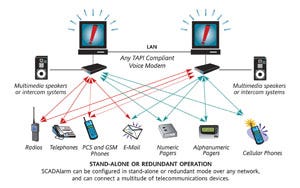

Wonderware products, starting with InTouch HMI and IndustrialSQL Server historian, and rolling into ActiveFactory reporting and analysis clients, SCADAlarm event-notification software and DT Analyst asset monitoring and overall equipment effectiveness (OEE) software, participate in every step of this process.

|

More than 45 different types of bottles are produced at the Blythewood plant, varying in colors, shapes and size. |

Each machine on the plant floor has a set of performance parameters that must be met in order to keep the line going. An injection molder, for example, tracks melt and coolant temperatures, injection and packing pressures and the speeds of various components in the machine. External factors, such as ambient temperatures and humidity, are tracked as well. The raw data from industrial and business systems throughout the plant is fed directly into the IndustrialSQL Server historian through an Ethernet-based network. Once captured, data can be accessed in real time by Wonderware's suite of plant-intelligence applications, including the InTouch visualization and control tool and DT Analyst software. Vital information is then sifted out and distributed to the people who need it.

“The biggest impact we've seen here is from DT Analyst software,” Iwancio says. “DT Analyst software enables us to address the real issues and not chase phantom problems. We know how many times something triggered an alarm and broke down, and for how long. This enables us to quickly identify the underlying cause and address it appropriately.”

DT Analyst software tracks OEE, which is a key metric for manufacturing organizations. OEE delivers a clear picture of what's happening with each individual piece of equipment on the plant floor and throughout the entire factory.

When used to its full potential, it can help companies avoid making unnecessary investments and help them focus on improving the performance of plant equipment that they already own. Additionally, Iwancio notes that DT Analyst software enables Amcor to prioritize its approach to issues “on the fly.” Using DT Analyst software, the company can ensure that problems that may have a significant impact on production receive attention and corrective action right away.

“Frankly we can't tackle everything that comes up over the course of a day or week,” he says. “We have to be able to prioritize, and Wonderware's production- and performance-management tools enable us to do that. My boss used to talk about going after the big rabbits, but how do you know when you are chasing a big rabbit? Now we know.”

Easy installation

The Blythewood facility installed InTouch and IndustrialSQL Server internally, but Iwancio relied on support from InSource Solutions (www.insourcess.com), a Wonderware value-added reseller, for the rollout of DT Analyst software. “We did one vertical line and then all the palletizers, which are a real bottleneck for us,” Iwancio says. “Because expanding it to the rest of the plant was really only a matter of adding connections, we hired a data-entry clerk and did the rest of the plant ourselves. Then it ramped up really quickly. We had it out to the whole plant in 60 days.”

|

SCADAlarm softeare has built-in browsers for fast configuration of information from other data sources. |

Thanks to the work that Iwancio has done with Wonderware, Blythewood has become a performance leader in the Amcor corporate family. A number of other plants have adopted Wonderware production and performance-management tools throughout their operations, while selecting DT Analyst software as a corporate standard.

According to Iwancio, Wonderware has provided Amcor with competitive advantages on two critical fronts. “It's enabled us to reduce the workforce and run a much leaner manufacturing operation, and it's helped us demonstrate our abilities to customers, which has given them a greater level of confidence in our manufacturing operations,” he says.

“Most people overlook the added benefit of qualifying your company to your customer. The customers are interested in seeing how you are going to provide a quality product. When you can show them what you can achieve with DT Analyst, IndustrialSQL Server, ActiveFactory and InTouch software, you can prove to them your commitment to maintaining quality production and that you will continue to provide them with a quality product. That's huge.”

More information is available: |

Wonderware, a business unit of Invensys Systems, Inc., 949/727-3200. www.wonderware.com. |

InSource Solutions, 877/467-6872. www.insourcess.com. |

About the Author(s)

You May Also Like