What makes mass production so flexible that it can meet individual demands?

September 28, 2016

Cosmetics maker Dr. Kurt Wolff GmbH & Co. KG can manufacture different products on one single machine thanks to Siemens technology, enabling individual demands to be met…the future of manufacturing, here today.

Small production volume – high flexibility

Fast and efficient – or customized and flexible. When it comes to consumer goods production, “either/or” was previously thought an unbreakable rule. Hard- and software from Siemens offers a new generation of machines no longer limited to strict either/or scenarios.

In the past 1 product = 1 machine was the rule for filling and related packaging lines. At best, a machine retool could be done to adapt new products, but this meant long, costly, and idle set-up times.

The machine builder Optima Consumer GmbH now uses advanced technology from Siemens offering a radically new approach to flexibility: one machine that can produce low volumes with increased productivity, and which is quickly and easily converted to accommodate the next product. Dr. Kurt Wolff GmbH & Co. KG, the first user, was able to dramatically reduce set-up times. The single machine currently manages five different products at one time and is continuously learning to accommodate more.

With the Multi-Carrier, custom versions of a product can be easily produced on the same line in a much shorter time.

This radical advance in mass production is made possible by two innovations:

1. The Multi-Carrier-System, which functions to more intelligently convey goods through the line compared to a classic production line. Where required, each single product may be modified individually.

2. A smart software concept from Siemens that provides the necessary intelligence for this type of dynamic control. Making it possible for the entire system to be highly automated, yet very flexibly.

Together, these innovations comprise a revolution in mechanical engineering.

Cosmetics maker Dr. Kurt Wolff GmbH & Co. KG uses an advanced solution from Siemens and OPTIMA to maximize filling and packaging production efficiency.

New standards were also set in the planning, development and commissioning of the machine by the Optima Consumer GmbH, Dr. Kurt Wolff GmbH & Co. KG and Siemens teams: The plant was largely developed and tested virtually. This way, the complex interplay of all the components is rehearsed and optimized on the digital twin long before the machine is actually built. The result: The time from concept to production-ready machine is considerably decreased.

“Everyone wants to have an individual solution,” Rainer Feuchter, ceo Optima Consumer GmbH. “It goes without saying that this requires us to think in a completely different way regarding machine building issues.”

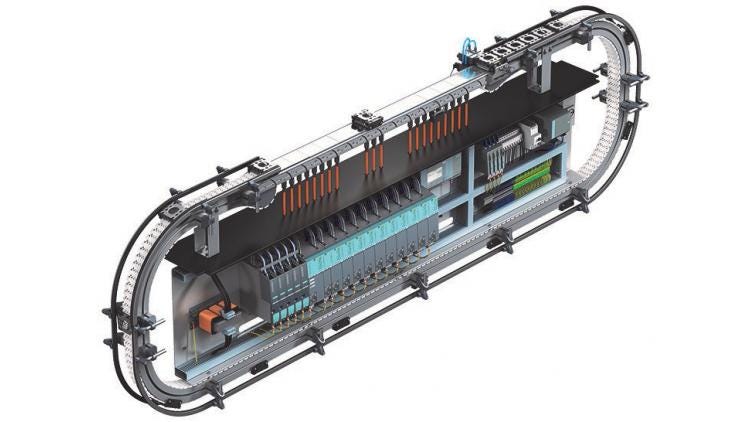

Brief on the Multi-Carrier System

The transport solution ensures maximum flexibility within the machine. In this context, the dissolution of the rigid concatenation* of conventional transport paths creates new freedom and provides maximum dynamics.

In this configurable transport system, the transport carriages, which are driven by linear motors, are flexibly moved to the individual units, e.g. filling, closing or labeling unit. The system moves freely and exactly synchronously to the process and can be integrated in the existing intralogistics—including seamless loading and unloading of the carriages. The other transport paths remain unchanged.

The modular concept allows a quick conversion of the machine to different formats, other product types or seasonal requirements. The integrated concept allows the end user to control the transport movements and Motion Control functionality as well as the coordination of additional machine modules.

Topology of the multi-carrier system

System configuration

• Simple, modularly structured mechanical basic system;

• Linear motor, basic profile and roller conveyor;

• Passive carriage without motor and active electronics for low wear and low vibration transport movement;

• Powerful controller: full integration of control and Motion Control tasks for the complete system.

Technology in detail

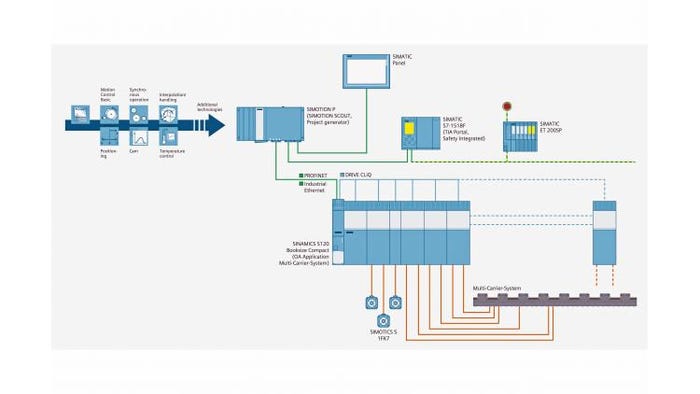

The control and drive package ideally supports the flexibility of the mechatronic system:

Flexible system integration: Mechanical and electric

• Operation of the multi-carrier system and further electric axes in a SINAMICS S120 axis group

• Use of all technological degrees of freedom of a SIMOTION (e.g., upwards and downwards synchronization on cam disks).

Multi-dimensional software architecture for efficient commissioning

• Free programming option based on the SIMOTION SCOUT engineering system (user-specific program section, simplification through standard application for Multi-Carrier-System with “zone concept“, mapping of a carrier on a virtual axis);

• Convenient integration of the basic system functionalities via an Open Architecture library (implementation of all segment transitions, switchover of the control modes closed loop - open loop, minimum collision detection);

• Efficient implementation of the machine application using the project generator easyProject.

Standard hardware

• The use of proven hardware ensures the wordwide availability of components and service.

Benefits

Cost Effective:

• Precise dynamics where the process requires it;

• Combination of linear track + intralogistics system;

• Reduced maintenance costs due to low wear.

Industry suited

• Robust and simple mechanics;

• Corrosion protected and easily cleanable surface;

• Protection degree IP65 (higher degrees of protection on request).

Easy to maintain

• Exchange of motors without disassembly of the track;

• Free access to motor cables;

• High availability due to standard components.

Siemens has posted a short video of the revolutionary Multi-Carrier-System in action.

See it at Pack Expo booth # N4941

For more information contact:

Binu Thomas Business Development- Packaging Industry

Siemens Industry, Inc.

Digital Factory

Factory Automation- Production Machines

5300 Triangle Parkway, Norcross, GA30092

Phone: 770-871-5654

Fax: 770-625-5662

Mobile : 678-427-9330

mail to: [email protected]

___________________________________________________________________________________

Explore cutting-edge packaging, manufacturing and automation solutions at PackEx Montréal, November 30, 2016 to December 1, 2016.

___________________________________________________________________________________

About the Author(s)

You May Also Like