Software integrates Sonoco's packaging systems

|

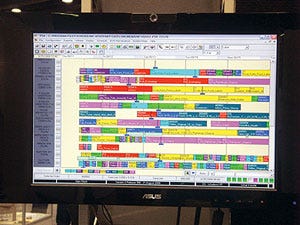

Scheduling software enables Sonoco to optimize work-center utilization. It streamlines and automates the scheduling process, eliminating manual entry, reducing errors and helping production planners generate optimal work schedules. |

Founded in 1899, Sonoco Products Co. serves industrial and consumer customers in 85 countries. The company produces packaging for a variety of industries and for many of the world's most recognized brands. Headquartered in Hartsville, SC, it operates more than 300 manufacturing and sales locations in 35 countries around the world and employs approximately 18,600 people.

Four disparate legacy systems

Over the past decade, Sonoco's Flexible Packaging Division has acquired a number of facilities, each utilizing different enterprise-management applications, and this was negatively affecting operations. “We had four disparate legacy systems all running on different technology platforms and databases. It was inefficient and difficult to get adequate levels of reporting and respond quickly to the needs of our customers,” says Ben Chan, director of division business systems, Flexible Packaging, Sonoco.

Earlier this year, the company decided to implement a new system to improve operational efficiencies, respond more quickly to customer needs and to gain immediate access to critical management information across its facilities.

Reducing the costs and risks of maintaining highly customized legacy applications also was a factor. Sonoco undertook a rapid software selection process that only considered industry specific Management Information System/Enterprise Resource Planning (MIS/ERP) providers with enough resources and implementation expertise to move quickly in the sales and implementation processes.

Solid management; long-time, happy clients and strong financial performance over time were also essential vendor requirements.

Software in seven facilities

Key software requirements include a functionally rich solution requiring minimal or no modifications to support packaging operations. The solution also needed graphic user-interface applications and web-based customer portal support.

After surveying MIS/ERP suppliers, Sonoco's Flexible Packaging group selected Radius Solutions, Ltd. (www.radiussolutions.com) and is implementing Radius' entire Pecas Vision operations suite across its seven facilities in the U.S. and Canada. The first site went live in only 3½ months, with two more U.S. sites to go live this year. An additional U.S. site and three Canadian sites are scheduled to implement the system next year.

The Pecas Vision system covers the following functional areas: customer service, estimating, order handling, production scheduling, shop floor data collection, and financial management.

|

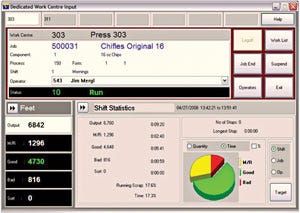

Shop-floor data-collection software provides real-time performance information back to Sonoco supervisors and schedulers. |

Specialized solutions to a range of sectors

The system installed at Sonoco provides specialized solutions to a range of sectors including flexible packaging, labels, folding cartons and commercial print. While most generic ERP solutions are designed to work in classic manufacturing industries, Radius Solutions' software is specifically written and designed to meet all of the setup, estimating, costing, production, inventory, and delivery needs of a printer or converter.

“Partnering with Sonoco to provide industry leading ERP Software and services is a great fit for us,” says David Taylor, president and CEO of Radius Solutions. “Sonoco had a very clear vision of what it required from an industry-specific software package and provider, and we are pleased they recognized the value we can provide to their organization.”

More information is available: |

Radius Solutions, Ltd., 312/648-0800. www.radiussolutions.com. |

About the Author(s)

You May Also Like