HPP putting healthy pressure on conventional processing methods

December 13, 2017

High pressure processing (HPP) systems vendor Hiperbaric shares an inside view on a market experiencing robust growth according to industry forecasts.

High-pressure processing (HPP), a nonthermal product treatment applicable for a wide range of food and beverages from juice to proteins, is an alternative method that’s putting pressure on conventional alternatives such as retorting and aseptic packaging.

Products are first packaged before the container is subjected to a maximum level of isostatic pressure during HPP treatment. It’s akin to a pressure cooker without the cooking, with enough force to kill bacteria, yeasts, molds and other potentially hazardous organisms. HPP also eliminates thermal degradation, a key distinction particularly for heat-sensitive products; the nonthermal process also retains products’ preprocessing nutrients and flavor. HPP products are distributed in refrigerated environments as an energy savings versus frozen distribution.

A recent report (Global High Pressure Processing Market: Trends Analysis & Forecasts to 2021) projects the HPP market to reach $1.1 billion by the end of 2021.

Another, High Pressure Processing Equipment Market - Global Trend & Forecast To 2022 published in January, foresees a robust $11.26% yearly growth rate—and a $500 million value—for the machinery segment of the market, seemingly a solid indicator reflective of HPP’s overall market growth prospective.

Packaging Digest sought an insider’s perspective in this interview with managers of HPP systems supplier Hiperbaric.

What are the key market drivers pushing HPP growth?

Hiperbaric: HPP continues to grow because it is providing manufacturers with the solutions to allow them to keep up with the paradigm shift in consumer behavior. Higher demand for clean-label products and a heavier emphasis on social and environmental responsibility leads to consumers opting for safer, high quality products.

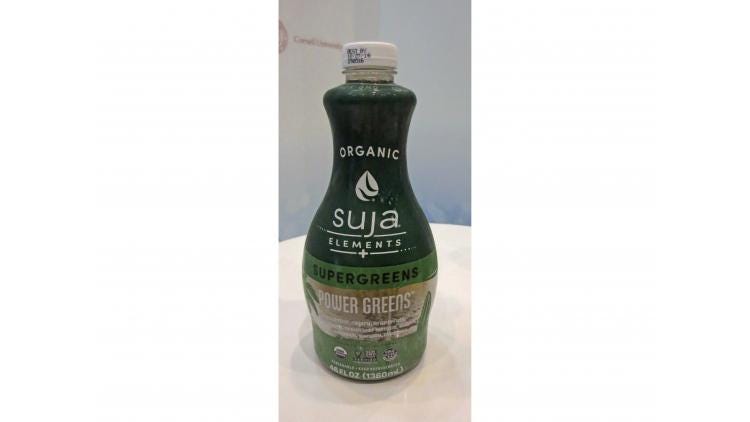

This Suja Supergreens bottled beverage exemplifies the inroads made in the healthy drinks and juice market by HPP packaged products.

What product markets are you seeing most HPP activity in? Perhaps meats and related proteins?

Hiperbaric: Since our equipment was developed first to treat meat products there remains a significant amount of machines that are used for meat applications. However, since the huge growth of juices and drink products, a significant amount of our machine installs in 2016 were for these markets. In summary, juices and drinks and dips and meats are dominating the HPP market.

In what regions are you seeing the largest growth?

Hiperbaric: The U.S. saw an enormous growth last year and while Europe has been stable in the past few years, we expect big growth there in 2017 and in Oceania and throughout Asia.

What kind of packaging can be used?

Hiperbaric: When thinking of pressure, our intuition leads us to think that the more rigid a material is, the more resistant it will be to pressure and the better it would be. This is not the case with HPP, since a more flexible packaging will lead to a more even transmission of the hydrostatic pressure throughout the product. The packaging design is limited to flexible and waterproof designs, meaning glass, rigid plastics or metals would not work.

How much of a constraint on growth is consumer confusion about the technology?

Hiperbaric: Educating customers is always a challenge with newer technologies. That is a key challenge facing HPP, but these days we see more consumers becoming familiar with the technology especially among the wellness foods space whose following is very stringent on the products they consume based on ingredients, how it’s processed, and the social responsibility of the brand.

HPP products continue to take over grocery-chain real estate along with new product offerings made with rare and unusual ingredients that are now available due to expanded distribution of HPP. Creating a better world with better food has always been our mission from the beginning and we continue to work with those who share our vision to accomplish exactly that.

For more information, visit Hiperbaric.

___________________________________________________________________________________

Hungry for packaging information and ideas? You’ll find that and a whole lot more served up in generous portions during WestPack in Anaheim, CA, February 6-8, 2018. For more information, visit WestPack.

___________________________________________________________________________________

A related HPP breakthrough

You know a market’s healthy when a vendor develops a custom ink for it, which is what CTI did with an HPP ink launched in early 2017. Akin to color-changing ink-jet codes printed on food can lids prior to retorting that turn from red to blue to confirm sterilization, the CTI ink appears clear when printed before turning color when exposed to high pressures. CTI reports that the first generation of the patent-pending HPP-indicator technology can differentiate between pressure exposure to less than 20,000 psi, to 20,000 psi and to 30,000 to more than 40,000 psi.

The CTI ink is presently available in water-based and ultraviolet (UV) cured inks and is applied to packaging the same as with conventional inks.

For more information, visit www.ctiinks.com

You May Also Like