Corner wrap labelers give superior efficiency

January 29, 2014

Finding the perfect cup of coffee is a daily pursuit for java drinkers everywhere. However, providing high-quality coffee beverages is a labor of love for Sara Lee Coffee and Tea. The company's love for coffee has lasted for more than 90 years with retail standouts such as Chock Full o'Nuts, Hills Brothers, MJB, and Chase and Sanborn.

Included in the Sara Lee Coffee and Tea stable is the foodservice giant Superior Coffee. In 1979, Consolidated Foods Corp. (now Sara Lee Corp.) acquired the Superior Coffee and Tea Company, and in 2000, Superior Coffee was officially renamed Sara Lee Coffee and Tea Foodservice. Along with the Moonachie, NJ, plant, Sara Lee packages the Superior brand in six other U.S. plants.

Foodservice giant

Providing coffee in bulk offers many challenges to a large company like Sara Lee Coffee and Tea. One of them is making sure that corrugated coffee cases are properly labeled with product codes, Julian dates and lot numbers. In early 2002, Labeling Systems, Inc. and distributor North America Corp. of Illinois provided Sara Lee's Moonachie packaging plant with a new corner-wrap labeling machine, the Model 1401, for its 12 coffee-packaging lines.

|

The 53/4-oz coffee pouches, top, climb to an accumulation area. After applying the leading edge label, left, the roller tamps down the case ID labels and does the same for the second panel of the case. |

In the past, Sara Lee was manually placing labels on corrugated RSCs containing various-sized coffee pouches. However, the process was slow, and ergonomic issues kept surfacing with packaging-line operators. In the distribution warehouse, workers had trouble seeing product labels that were located on the side panel of the corrugated cases for picking. Michael Sobers, plant manager at Sara Lee Coffee and Tea, says, "We went to a corner-wrap machine for two-panel visibility. The corrugated cases are stored in slots, and workers needed to see the label from different angles. Now, the same information is on two panels of the case."

The print-and-apply labeler is capable of holding a 12-in. label roll and prints up to five lines of text on the white, single-layer pressure-sensitive paper labels that run on all 12 of Sara Lee's packaging lines. North American Corp. supplies the p-s labels. The printer can produce up to 25 characters per line and has the ability to print bar codes and graphics. This is important, because Sara Lee provides copacking services for private-label brands. These customers require logos or graphics on their labels.

With private-label customers and Sara Lee's numerous brands, product volume can be quite high. Sara Lee needed consistent and durable machinery for all 12 packaging lines. Sara Lee runs two to three shifts per day, depending on the season?its coffee production increases in the fall and winter?and produces up to 450 filled corrugated cases of coffee per line, per shift. With the 12 lines in the plant, there is a packaging buzz that is more intense than a double Americano coffee beverage. Bill Hingle, marketing services manager at Labeling Systems, says, "The labeler is all-mechanical. We kept the design simple, so setup and changeover are quick and easy."

A line breakdown

PD visited and toured one of the Superior Coffee packaging lines that was producing 53/4-oz pouches of ground Superior brand coffee. The packaging line starts with a Bosch Model 330, vertical form/fill/seal machine that creates and fills pouches from a laminated film substrate. The filled pouches then move to an incline conveyor, where they are transported to an accumulation area next to the RSC corrugated cases.

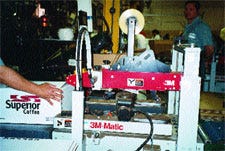

On all 12 lines, the corrugated cases are manually erected. The case-filling stations at all times have at least two empty erected boxes. From the accumulation area, a distribution arm takes individual pouches and fills one case at a time with a predetermined number of pouches. For this Superior brand run, 150 pouches fill one corrugated case. Once filled, the case is removed manually and the second, unfilled case moves in to be filled. From there, the cases are manually moved to an infeed conveyor attached to a 3M-Matic™ case-sealing system. The system seals the top and bottom panels of each case with adhesive tape, also supplied by 3M. The cases are then conveyed to the print-and-apply system.

A conveyor belt then transfers the corrugated cases to the labeling head of the system. The labeling head applies the first part of the

|

The labeling head's applicator moves with the corrugated case to wrap the label on the front, or the leading edge, and side panel of the corrugated case in approximately two seconds. |

corner-wrap label to the leading edge–front panel–of the corrugated case. The labeling head's applicator moves with the corrugated case to wrap the label on the front and side panel of the corrugated case, in approximately two seconds. The labeling system features a high-volume vacuum design that holds the label in place while the corrugated case passes through the labeling head. The vacuum system uses a pancake-style fan to create suction to keep the label in register. Inside the vacuum system, a vacuum chamber is designed to prevent particulate matter from infiltrating the labeling head. Hingle adds, "The vacuum system was an important feature for Sara Lee. Air travels straight to the applicator assembly, and the ground coffee does not present any issues."

The labeling process starts with 12-in. label rolls that go through a set of rollers that tension the web, ensuring critical control accuracy at the labeling head. Then, labels move to a SATO America M8485Se printhead, where they are printed with a Julian date, code numbers and a product item number. Keeping with the straightforward design,

|

The filled corrugated cases are fed into the case-sealing machine. |

the label information can be input directly into the machine via a keypad. However, Sara Lee uses a database networking system to enter label information. At the labeling station, an operator inputs a product identification code via a keypad that is then sent to a central computer server. The central server provides a product database for all IDs received from the different packaging lines and sends the label information for the specific product to a packaging line printer. Sara Lee's Sobers says, "That's a challenge. We need to make sure the label information is there when we need it."

For the Superior line, the label size is 1034 in., and the system is capable of producing a size as small as 130.25 in. The system has a print resolution of 203 dpi and is capable of 60 labels/min. Sara Lee averages 10 labels/min for this particular Superior line. With the steady volume of corrugated cases, the labeling system holds its own, PD is informed. Sobers says, "There's not much maintenance with the labeling system, and the biggest challenge is displaying the customers' graphics on the cases."

From there, the labeled corrugated cases move to a weigh conveyor, where they are checked and are then transported on Rapistan conveyors to a distribution warehouse.

Teamwork

With such a huge undertaking, LSI worked closely with Sara Lee to integrate all 12 labeling systems on these lines, PD is informed. "Most of the packaging lines are located in a tight area, and we constructed a layout to conform to that environment. That called for a lot of coordination between LSI, North America Corp. and Sara Lee," Hingle says. The coordinated efforts have worked, and Sara Lee is reaping the benefits of a more efficient workflow in the packaging and distribution channels. In this example, the packaging line provided the boost along with the coffee.

More information is available:

Label applicator: Labeling Systems, Inc., 201/405-0767. Circle No. 201.

Distributor, p-s labels: North American Corp. of Illinois, 708/449-1400. Circle No. 202.

Vf/f/s machine:Robert Bosch, Corp., 616/466-4000. Circle No. 203.

Case-sealing system: 3M Packaging Group, 800/362-3550. Circle No. 204.

Print engine: SATO America, Inc., 314/846-0892. Circle No. 205.

Conveyors: Siemens Dematic (formerly Rapistan), 877/725-7500. Circle No. 206.

About the Author(s)

You May Also Like