Top 5 labeling trends in today’s global supply chains

August 7, 2017

More than 800 supply chain and information technology (IT) professionals from 32 countries participated in the fourth annual “Top 5 Trends in Enterprise Labeling” survey conducted by Loftware. The results show five significant shifts in labeling that are impacting global supply chains at an unprecedented level.

Supply chains and the solutions used for managing them have become increasingly important as businesses become more global and interconnected. This is why it’s critical to identify, understand and measure how labeling has a strategic impact on your supply chain and your company’s business growth.

1. Labeling is a global initiative.

Approximately 65% of those surveyed in the recent poll claim they recognize the necessity of having labeling addressed on a global scale. More than half of respondents work for companies that maintain labeling across a global operation, with five or more locations. Labeling, which intersects the supply chain at all levels, has become mission critical in meeting evolving customer requirements, keeping up with emerging regulations and avoiding disruptions from the manufacturing line to the warehouse.

At the same time as companies are looking at labeling on a global basis, they must consider how to effectively deploy and maintain their labeling solutions, how to support enterprise-wide labeling changes and how to scale effectively as their businesses continue to grow and enter new markets.

2. Enterprise labels are changing.

The barcode label is simply not what it used to be. Companies that understand this will find themselves ahead of their competitors in meeting evolving customer demands. As customer and regulatory requirements increase, companies have been forced to make a record number of label changes and add more and more content to their labels. Over 80% of respondents reported that labeling requirements have become more complex in the last three years.

To meet these increasing demands, labels today must be flexible and data driven to support the nearly limitless variability in requirements that exist. In many cases, the key is enabling business users with a simple mechanism to make label changes, as well as integrating with enterprise applications to automate labeling processes. This increases efficiency, leverages existing investments and reduces the need for countless permutations of label templates.

3. Labeling drives the bimodal supply chain.

As the complexity of a global supply chain increases, so too does the need to track goods and products that travel through it.

American research and advisory firm Gartner indicates “Digital innovation will lead to a new approach to the supply chain.” It further claims,“The divide between what the supply chain provides and what the enterprise needs is widening. Closing that gap requires a new, agile approach to investment in technology, leadership and talent.”

More than 63% of respondents report they are currently combining digital technology with traditional practices to improve supply chain operations. This intersection between physical and digital worlds within a supply chain is intended to“renovate legacy environments into a state that is fit for a digital world.” This approach allows manufacturers to gain “the best of both worlds” by embracing digital technology and new business models while continuing to use reliable physical processes that have worked well in the past.

Labeling plays a key role in representing the bimodal supply chain considering the label is a physical representation of digital information, which is often encoded in a barcode.

4. Labeling extends upstream and downstream.

Companies that don’t attempt to connect business partners across the global supply chain are missing opportunities to meet new customer demands, grow into new markets and increase competitive advantage.

More than two thirds of those surveyed (67%) see value in having suppliers print labels using a shared solution to ensure proper labeling. This is because labeling plays an important part in generating value from the supply chain network to improve efficiency and meet customer demands.

When businesses extend labeling to partners and suppliers, they are able to avoid downstream processing errors and eliminate the need for relabeling. It also removes the risk associated with shipping preprinted labels and allows companies to realize savings from cost of returns, improve brand consistency and ensure label accuracy.

Extending labeling both upstream and downstream has a host of benefits, including eliminating costly relabeling and ensuing integration of aftermarket services.

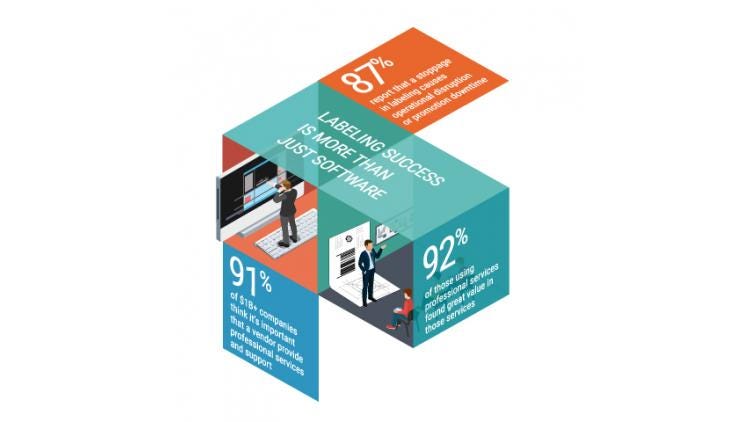

5. Labeling success goes beyond just software.

Businesses today are relying on seasoned labeling professionals for best practices, implementation consulting, training and knowledge transfer to help ensure success.

They understand that working with these experts can help minimize or eliminate production stoppages, optimize supply chain operations, improve customer satisfaction and ultimately increase business. These professionals are able to help them deal with the many unique labeling requirements to address dynamics of different industries, products, geographies, regulations and business models.

More than 92% of respondents using professional services found great value in those services. With this focus, expectations have increased for labeling professionals to understand and provide guidance on evolving industry standards and regulations, business processes, and regional nuances, along with expert around-the-clock support to enable continuous operations.

Josh Roffman is vp of product management at Loftware. He has more than 20 years of product management experience with leading enterprise software companies. He is responsible for defining Loftware’s product strategy and overseeing all corporate marketing functions. Specializing in the impact of supply chain trends on enterprise labeling, Roffman frequently speaks at industry events.

About the Author(s)

You May Also Like