Granola packager benefits from new filling equipment

|

A new packaging line at Erin Baker's Wholesome Baked Goods, Bellingham, WA, includes both horizontal and vertical machines to produce different size bags of the company's popular homestyle granola. The company was founded in 1996 to produce and market founder Erin Baker's Breakfast Cookies; a breakfast or snack for people on-the-go.

Erin Baker's introduced its granola in 2006 and installed a new packaging equipment from Weighpack Systems Inc. last year. “We looked at a number of different systems, but we wanted to run preformed 12-oz bags, and the Weighpack seemed to be the best suited for us,” says president Bryan Geschwill. “We also wanted to produce smaller bags on a form/fill/seal machine, so we also bought a Weighpack machine for that. We sent one of our production people to Weighpack to learn about the machines, and Weighpack came out here for installation and startup.”

|

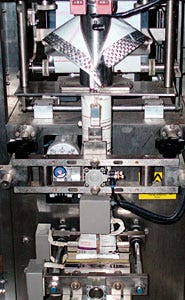

After the bag is placed into the hf/s machine, a cone-shaped device descends to open it completely. At the next station, the filling funnel |

Horizontal machine runs premade bags

Erin Baker's installed WeighPack Systems' Swifty 3600 intermittent-motion hf/s machine for its 12-oz premade bags, a Vertek Junior continuous vf/f/s machine for its 1.5-oz bags and a 14-head CombiScale, Inc. multi-head scale that automatically weighs its granola products into both bagging machines.

The Swifty machine uses premade, zippered standup bags that are placed in the bag-loading station. To start the operation, the bags are automatically taken from the station with a vacuum mechanism and are transferred to a standup position. From there, the bags are advanced using a walking beam that moves them into the various stations of the filling and sealing process.

These stations include an automatic zipper-opening device, a filling section where a transitional funnel dispenses product into the bag, a gas-flushing station, a mechanical bag-spreading station for a wrinkle-free seal and a heat-seal station where the bag is sealed and a hole that the bag can hang by is punched in the top.

|

On the intermittent h/f/s machine, preformed |

Vertical machine runs film on a roll

The Vertek Junior vf/f/s machine runs printed film on a roll that is mounted on the back of the machine. The film is moved into the forming section by a servo-driven pull belt and passes over a series of rollers and dancer bars at the top of the machine that maintain the proper back pressure on the film as it is pulled through the machine.

The film then passes around a forming tube on the front of the unit, and a vertical heating element produces a vertical overlap seal. Product drops from the overhead scale through the forming tube into the intermittent-motion formed cylinder of film as it leaves the vertical forming section.

|

The hf/s machine uses premade, zippered standup bags that are placed manually in the bag-loading station. |

Next, the film passes through the pneumatic sealing jaws, which move in against the film and heat a horizontal seal across the film. At the end of each sealing cycle, before the jaws disengage, an air-actuated blade shoots out from the center of the jaws and cuts the bag loose, after which the bag drops onto a takeaway conveyor. A sensor mounted on the film carriage detects an eyemark on the film, which initiates the start of each cycle. This compensates for any changes in the film length and ensures that the film for each bag is in perfect registration. This system basically tells the horizontal sealer and cutoff knife when to energize.

|

The scale controls are mounted near the scale discharge, for easy access. After the film is formed and sealed into a tube, the product drops from the overhead scale through the forming tube into the intermittently moving formed cylinder of film as it leaves the vertical forming section. |

|

PLC controls machine functions

The Swifty bagger includes an Allen-Bradley PLC and PanelView operator panel from Rockwell Automation. The Vertek machine uses a Mitsubishi Electric Automation Inc. PLC. On both machines, the PLC maintains the recipes for all of the products in memory, and the operator can recall them at a touch.

The unit automatically sets the operating parameters, including the sealing temperatures and bag lengths. The screens can also be actuated to display the settings currently in use, causes of operating problems and maintenance requirements.

Mobile scale

Product for both machines is weighed and dispensed by the 14-head radial-weighing system from CombiScale Inc. that is located above the machine. Weighpack Systems uniquely installed the scale on a hydraulic jack mounted on wheels in order to provide the most flexibility possible when moving from one bagging machine to the other. An operator manually positions the scale above whichever machine is running that day and connects it to the tube into the bagger. The product is delivered by a flighted elevator up to the weigher's central funnel.

Vibrating dispersion pans transfer the product from the central funnel to 14 radial feeder hoppers, which, in turn, move the product by vibration to the weigh buckets. Each vibratory hopper adjusts the strength and duration of vibration to ensure an ample supply to the bucket.

The weigher's microprocessor selects a combination of buckets (generally three or four) that cumulatively equal the closest weight to the total bag weight without being under that weight. The selected buckets then open and discharge their contents down the discharge chute to the bagger. The scale features an easy-to-use operator interface that provides a clear display of charge weight as well as various statistical data.

“Both machines have worked out well for us,” says Geschwill

|

|

Vibrating dispersion pans transfer theproduct from a central funnel to 14 radial | The scale is uniquely installed on a hydraulic jack that is mounted on wheels so it can easily be moved from one |

.

More information is available: |

Weighpack Systems Inc., 514/422-0808. www.weighpack.com |

CombiScale, 847/806-0606. www.combiscale.com |

Mitsubishi Electric Automation Inc., 847/478-2100. www.meau.com |

Rockwell Automation, 414/382-2000. www.rockwellautomation.com |

About the Author(s)

You May Also Like