The case of the high-speed slows

April 25, 2014

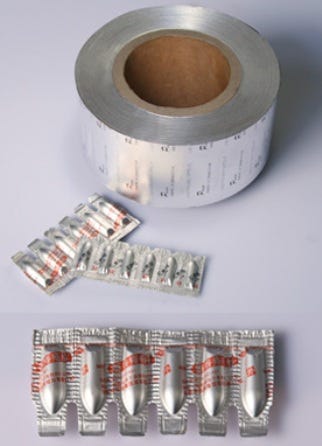

Suppositories packaging

Alex was on the blower sounding confused.“KC, it seems like the faster we go, the behinder we get. I’m not meeting my production numbers and don’t know what to do. Can you help?”

The answer to that is always “Yes!”. After all, I am the Packaging Detective.

Soon after we hung up I was with Alex in his plant and he was showing me the problem. The product was 3/8 in. diameter suppositories and they were sealed between two strips of poly coated foil. The real problem was that the product was too thick for this kind of package but there was nothing that could be done about that.

The issue Alex was having was that the process generated about 30 percent rejects because the film didn’t seal correctly.

“Fiddlesticks on sealing rejects!” I expostulated. “Proper sealing must balance time, pressure and temperature. What’s needed here is lower temperature and pressure plus a longer dwell time. The only way to get that is to slow down the machine.”

“But our production targets are based on 60 ppm (packages per minute). If we slow the machine we won’t meet them.” Alex said.

“You’re are not meeting them now.” I told him. “Running 60 ppm with 30 percent rejects gives you an effective speed of 42 ppm. Slow it to 50 ppm, get rejects under 5 percent and your effective speed is 47 ppm. The 12 percent speed bump plus reduced rework and scrap will let you hit your numbers.”

Faster isn’t always better.

KC Boxbottom, packaging detective, is on the case to solve tough packaging puzzles. He is the alter-ego of John Henry, CPP. Known as the Changeover Wizard, Henry is the owner of Changeover.com, a consulting firm that helps companies find and fix the causes of inefficiencies in their packaging operations. He produces a free monthly newsletter called Lean Changeover, which contains articles and tips on changeover and related issues. Reach him at [email protected].

About the Author(s)

You May Also Like