Today’s Case Packers Tap Robotics for Flexibility

Constantly changing packaging requirements from brand owners and co-packers push new case packer technologies and higher performance.

The up-and-coming generation of case packers is a far cry from the cam-driven models that once dominated this market niche. Today’s case packers feature a trove of advanced components, including robotics, smart controls, and vision systems that increase reliability, streamline changeover, and automatically correct operational problems.

Today’s advanced models are also more flexible than ever. Increased variability of stock-keeping units (SKUs) and demand for retail-ready packaging from consumer packaged goods companies are driving demand for flexible pack patterns and variable package formats. To meet that need without sacrificing line speed, equipment makers are incorporating robotic collation and case loading.

At the same time, labor dynamics have made ease of operation more important. Equipment manufacturers are developing more intuitive human machine interfaces (HMIs), which assist operators with case packer use and troubleshooting. In addition, predictive maintenance features are helping packagers to maintain their case packers and prevent unplanned downtime.

Automated changeover capabilities are also making it faster and less onerous to switch case formats or product configurations — even as case packer footprints get smaller.

Several equipment-industry insiders participated in the following Q&A, offering their views on how far the equipment has come, as well as the market and technology changes shaping the future of case packing. The participants in this exclusive Packaging Digest Q&A are:

• Maria Cancino, product line manager at Brenton, a ProMach product brand

• Rick Gessler, vice president of engineering at Delkor Systems

• Daniel Maeyaert, vice president of manufacturing operations at Fallas Automation

• Scott Williams, northwest regional sales manager at BluePrint Automation (BPA)

What recent advancements have you seen in case packers?

Cancino: Many of the advancements that we have seen in recent years follow the trends for overall packaging automation — increased demand for SKU variability and a shortage of labor impacting the number and training of operators.

The high variability of SKUs has caused case packer manufacturers to respond with more flexible, higher-rate machines. For example, five years ago, companies may have run six- and 12-packs consistently with few changeovers; now we are seeing two-, three-, and four-packs in addition to the six- and 12-packs. The upstream equipment continues to fill at the same rate, but now with the lower-count packs, the case per minute has increased.

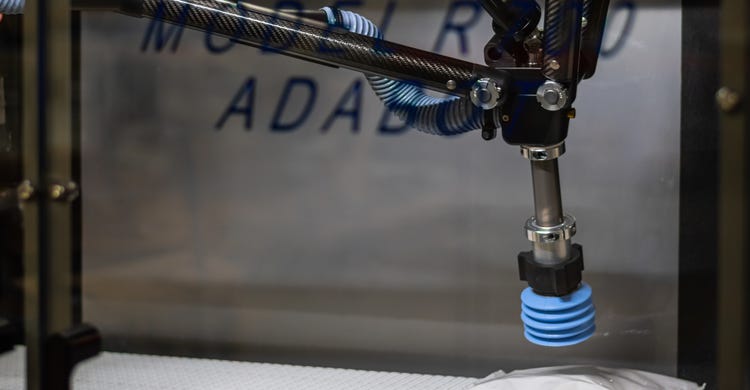

To address this need for flexibility and speed while keeping overall throughput the same, we have developed a pitchless design for our product infeeds, as well as the case packer’s main design, to get to the faster rate and address the varying pack patterns. We are also incorporating more use of robotics and robotic vision both for collation and the case packing itself, adding to the overall flexibility of the machine.

The second trend — labor shortage as it relates to trained operators — we see reflected in our case packers needing to be easier to use and troubleshoot, and needing relatively little oversight. We have addressed these concerns through the improvement of our HMIs to be more intuitive and similar to smartphone or tablet applications. This decreases the overall training time needed for operators to interface with our machines. Additionally, we offer options to automate changeover or provide assistance to operators during changeover, which also decreases the machine-specific knowledge an operator needs.

Gessler: Case packers are trading physical parts and hardware for more sophisticated controls and advanced technology. Our latest generation of smart machines incorporates technology that combines product flow and pattern building in an innovative manner, reducing machine complexity while increasing reliability and package-format flexibility.

These advancements are critical, as retailers and ecommerce continually drive a changing landscape in terms of packaging requirements. As producers select their next packaging lines, it is important for them to be able to invest in a system that has the flexibility to keep pace with these ever-changing packaging requirements, helping to protect them from packaging-line obsolescence.

Williams: There have been quite a few advancements in case packing recently. One advancement I am seeing more of is the use of different styles of robots working together to create new case-packing equipment, like our model that uses delta-style robots to load directly to cases for horizontal patterns. Or the delta can pattern-form the product onto a belt and then use an articulating robot to collect and load vertical patterns into cases.

Another example is our case packer that combines a delta robot with an integrated robotic case erector to pack snack bags vertically into cases.

Maeyaert: The most recent advancements in case packing have circulated around making the machine easier to operate with less personnel. That includes predictive maintenance that allows the machine to tell the maintenance staff that the machine needs to be maintained, or that the machine is about to fail. This is in contrast to staff having to check on machines regularly or rush over because of a failure emergency. For operators, that has meant ease of use with less knowledge. Another advancement is adding centerlining devices that require less knowledge of the machine, and more instructions fully available to the operator right at the machine.

Technologically, servo technology has improved quite a bit to increase machines speeds. A lot of effort has also gone into work by electronics manufacturers to provide as much information as possible about their component to us. That allows us to use that data to better understand how the machine runs over its lifetime.

From the market, there has been a large push the last five years for retail-ready. End users are starting to figure out what works for them, but there are still regular changes to what is needed in this area.

How do these advanced systems compare to the existing standard equipment?

Gessler: Where traditional machines use hard automation — for example, chains, buckets, cams, and pneumatic pushers — the latest generation of equipment replaces legacy technology with advanced robotics, vision systems, and smart controls that can detect and correct issues on the fly. These changes also minimize the moving parts in the machine, increasing reliability and minimizing changeover points, which reduces the time required to transition from one case format to another.

Many of the latest advanced case-packing systems also offer auto recovery from faults or product mis-feeds. This capability minimizes the impact to production when nonconforming products enter the system.

Williams: They provide more flexibility with fewer change parts and smaller footprints. Standard case-packing equipment on the market today still has its niche and fits some users and applications very well. However, the newer styles of case-packing equipment deliver some strong advantages that shouldn’t be ignored. Newer styles of case packers fit into smaller footprints, have a wider array of product and patterns they can pack with fewer change parts, and require less operator intervention.

Maeyaert: Most equipment on the floor right now runs until it breaks — it’s all reactive maintenance. Plants are also just gleaning the surface of the data available to analyze how their lines run. Most machines don’t use the data available to them and there is much more data available to analyze with added sensors.

Cancino: In many cases, if the advancements hold value for the majority of our markets and customers, we are rolling out the innovation within our standard equipment. If a more limited customer base has interest in the advancement, it could be offered as a standard option to our equipment. In either case, we continuously seek to drive innovation and technology to provide more value to our customers and address their automation concerns.

What are the benefits of these advancements for packaging machinery buyers/users?

Williams: Benefits include less operator intervention, more uptime, the machinery fitting into existing plants, and being able to do more with one machine.

These advancements, as I mentioned, increase the flexibility of the case-packing equipment, allowing users to pack a variety of products and patterns, going into multiple styles of cases, whether they be vertically or horizontally packed, all while fitting into a smaller footprint and having fewer change parts.

Maeyaert: Machinery users can use these new advancements to avoid unnecessary downtime. They can plan needed downtime around their schedules. They also allow the plants to run their machines more efficiently with a less knowledgeable staff.

Gessler: Recent advancements ensure quicker package-format changeover coupled with the flexibility to meet the packaging needs of a range of customers with a single case-packing line. This flexibility also lengthens the life span of the case-packing line, as it can adapt with the change in products and package formats.

Modular machine designs and a compact floor footprint help to better fit the exact speed and size requirements, as opposed to the one-size-fits-all designs of old. Ergonomic, operator-friendly designs are built into these cutting-edge case packers, such as large walk-in doors, push-button changeover, LED status glow lights, and more. These adjustments make a noticeable difference in day-to-day operations and reduced downtime.

Cancino: Besides alleviating the burden of training for the operators, the biggest benefit of the advancements I mentioned is additional flexibility and reducing the overall footprint of the machine.

Through the use of robots and our pitchless designs, we are able to handle the complexity and number of SKU and pack-pattern variations that our current customers need. We also work with customers to “future-proof” the machines to allow customers to import new pack patterns or additional SKUs, all within a compact footprint. We can use robotic vision and collation to add to the machine’s flexibility in handling multiple flavor packs or interweaving packs. This technology not only works for initial deployments but also makes it flexible enough to be deployed in a new line, should it be needed.

What areas in case packing still need work and why?

Maeyaert: We are just starting to get into machine learning and artificial intelligence (AI). There are data available and sensors to obtain it, but much of that cost is still high. It requires desire by the end user to put these capabilities on a machine. Prices are still too high to include them as standard. Also, the more data that case packer OEMs have, the better we can make our machines run. Plants have held that data very close to their chest for obvious reasons, but the more data we can obtain in real time, the better we can serve our end users.

Gessler: So often, the packaging itself is overlooked. Traditional brown-box shippers — regular slotted container (RSC) cases — are still used by many producers. These cases often use excess material, which is waste, driving high per-package costs.

There is an opportunity for these producers to shift to a more efficient box style, reducing their packaging costs in many cases by 15% or more. These efficient case formats are formed from a flat blank, without a manufacturer’s seam. Erecting from a flat blank can enable increased throughput rates by using more advanced case-erecting technology, such as servo-driven erectors.

Inferior corrugated board is an issue on a lot of legacy equipment out in the field. Addressing this are erectors that incorporate adjustable tooling that enables quick changeover, easily handles warped corrugated, and uses dynamic compression to achieve perfectly square cases. In addition, the dynamic compression ensures excellent case integrity by applying 100 pounds of compression force to each glue joint.

Williams: More automated changeovers, increased flexibility, and ease of use are a few. We are always searching for ways to improve upon our existing equipment or create something totally new that changes the preconceived notion of the way things should be done or has been done in the past.

Some areas where we see opportunity for improvement with regard to case packing include: increasing ease of use of the case packers through reduced amount of spare parts needed, having more automated changeover capabilities, and creating a user experience in which the equipment is simple and easy to operate.

Cancino: As the market continues to move toward more and newer uses for flexible packaging, we continue to be challenged with how to handle the new packaging more efficiently. Even for some of the existing technology, we continue to look for ways to improve the speed, collation, and overall handling of the product.

Our customers challenge us to provide smaller footprints and faster pack rates as we see much of the labor of displaying product at retail stores move to consumer packaged goods manufacturers — they are being challenged to provide display-ready packaging for a smaller shelf space. We partner with our customers to drive new ways to orientate and pack product within the cases to reduce labor at the retail end.

What’s next and when might we see further improvements in case packers?

Maeyaert: Linear servos are what will take machines to the next level. Servo racetracks and linear servo actuators have improved a lot in the last couple years. As the cost drops, this will allow machines builders to replace air cylinders with servo actuators. These will smooth out and speed up machines and allow fully coordinated motion on all aspects of the machine.

Servo racetracks eliminate complicated chain-and-belt tracks and add whole new levels of freedom. It will allow us to create machines that operate as smoothly as the old cam machines, but with the speed and reliability of servos.

Cancino: As we continue to partner with our customers, we envision more robotics and linear servos being included in case-packing machines, to cut down on overall footprint. We see more advances to make machines less operator driven and enable our customers to have one operator for several machines vs. the 1:1 ratio we have seen in the past. We also expect the Industrial Internet of Things (IIoT) to drive more preventive maintenance schedules and help reduce unplanned downtime.

Williams: Next up is Industry 4.0 and remote monitoring. We are definitely seeing a push to have increased monitoring of systems within our portfolio. Industry 4.0 is still a buzzword we hear a lot, and we are working to provide even more data and integration than we have before.

Customers are asking for case packers to have machine-to-machine communication and provide data back in real time, allowing manufacturers to connect in an environment of data, processes, services, systems, and IoT-enabled assets, while monitoring them from anywhere in the world.

Gessler: Case design has been relatively stagnant over the past decade, with retailers only in recent years shifting to shelf-ready packaging. With the current, growing ecommerce markets, there is a lot of change that case packers will need to accommodate.

I envision more collaboration between equipment providers and package designers, going forward. We have both functions in-house. Our Package Lab is fully staffed by packaging engineers and design and test equipment that our customers can use for free not only to help reduce packaging cost but also to achieve the goals set forth by the retailers — such as shelf-ready packaging, Walmart’s Project Gigaton, and more. This type of tightly connected development enables producers to keep pace with their customers’ needs, and it enables equipment providers to stay ahead of the curve.

About the Author(s)

You May Also Like