'Sweetheart' of an operation

January 29, 2014

|

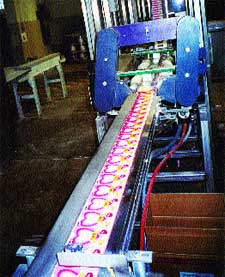

The timing screw system orients cartons from a vertical cartoner and delivers them to a sequential transfer system feeding a horizontal cartoner. |

Everybody loves a bunch of sweethearts–Necco® Sweethearts® Conversation Hearts, that is–those delicious, little, pastel-colored candy hearts famous for their sentimental messages of love, admiration and friendship. Celebrating its 155th anniversary, the New England Confectionery Company (NECCO) is the oldest multiline candy company in the U.S., and has 85 percent of the Sweethearts Conversation Heart business worldwide.

Sweethearts Conversation Hearts are primarily produced at the NECCO headquarters and main manufacturing facility in Cambridge, MA, which produces nearly half a million 1-oz boxes/day. The candy hearts' primary package is a 21/4x 37/8-in. carton running on a Tisma continuous-motion, vertical cartoner with a volumetric filler, followed by a Tisma Series 60 intermittent-motion display-pack horizontal cartoner.

A conveyor moves the candy boxes from the vertical packer to a Tisma collation system, which feeds the display-pack cartoner. The hitch in the relationship between the two cartoners occurred when the boxes of candy were not under positive control as the cartons entered the collation system. At the design rate of 500 boxes/min, this created jams.

Tisma turned to Morrison Timing Screw for a cartoner go-between that would orient the cartons properly, provide consistent speed, maintain equal distance between the cartons, and unite the rate of product flow from one end of the system to the other. After analyzing the situation, Morrison solved the problem by developing a timing screw system that maintained control of the cartons as they moved from one machine or operation to the next by dividing the single lane of containers into two lanes and combining them into groups of three in each lane. Then they were timed to go into the collation system in the desired groups of three boxes for transfer to the horizontal cartoner, where they were placed into display cartons holding 27 or 36 boxes, as required. The integration of the Morrison timing screw system made an immediate and immense difference.

System runs 27 or 36 boxes per carton

"The Morrison timing screws sure did turn things around smoothly and quickly," explains John M. Coletti, NECCO plant engineer. "The timing screws divide the incoming boxes into two separate rows with three packages in a group each time they go into the collation system. The system lays them in the correct position, so they can be grouped into three packages of three each at a right angle for nine total, indexes nine, accepts nine, indexes nine for thirty-six packages, or only three times for twenty-seven in a carton. These cartons then are put into display boxes and cartoned for shipment."

|

Timing screw system, right, orients cartons entering the horizontal cartoner, above. The system provides consistent speed and maintains equal distances between the cartons, which leave the system in groups of three. |

"Consider this: 500 boxes per minute times sixty minutes per hour times two shifts of eight hours each equals 480,000 boxes per day. It's fantastic! We've never had a problem with the Morrison timing screws since their installation. They just run and run, two shifts per day, day in and day out, orienting the boxes, grouping them into three's and spacing them so they go into the collation system in the right order and time," Coletti enthuses.

Says Joe Clark, product manager at Tisma, "Morrison really came to our rescue. They rapidly sized up the situation, brought us the right timing screws, installed them and gave our cartoning system the needed boost in efficiency to meet the production speeds we promised our customer. We felt on top of the world when the situation at NECCO was resolved.

"Morrison truly goes above and beyond when it comes to problem solving and customer service. We can't ask for anything finer. That's why we turn to Morrison time after time when we need timing screw systems for our equipment."

More information is available:

Cartoners: Tisma Machinery Corp., 847/427-9525. Circle No. 220.

Timing screw system: Morrison Timing Screw Co., 708/756-6660. Circle No. 221.

You May Also Like