3D printing advantages solidify for packaging

February 20, 2015

This week at Pack Expo East, David Macfie of Cimquest provided an overview and update of 3D printing technology, citing companies including The Dial Corp. and Silgan Plastics that were using it for packaging.

“By noon today, everyone in this room will have been impacted by 3D printing,” declared David Macfie of Cimquest, a Value Added Reseller (VAR) of 3D printing systems operating throughout the northeast U.S. that also offers 3D scanning services. Macfie spoke during the kickoff session of the 3-day International Society for Pharmaceutical Engineering (ISPE) conference before the Pack Expo East exhibition opened on Monday in Philadelphia.

Macfie is the company’s director of Stratasys 3D printing system sales, which the company has been selling since 1990. He referenced the fact that everyday items from the snooze button on a Bose audio system to Colgate toothbrushes and more have had a design assist from 3D printing, a market forecast by ID Tech Ex to reach $20 billion by 2025; McKinsey estimates that the economic impact of the technology could reach $550 billion a year by 2025.

“Applications drive growth,” he said of the 20% to 30% CAGR 3D printing market, “and touch every market except finance.”

“A sophisticated hot-glue gun”

Macfie also noted the following:

There are seven different kinds of 3D printing methods each with their own strengths and weaknesses within the two basic types of additive and subtractive;

Hybrid systems are available that have both additive and subtractive operations;

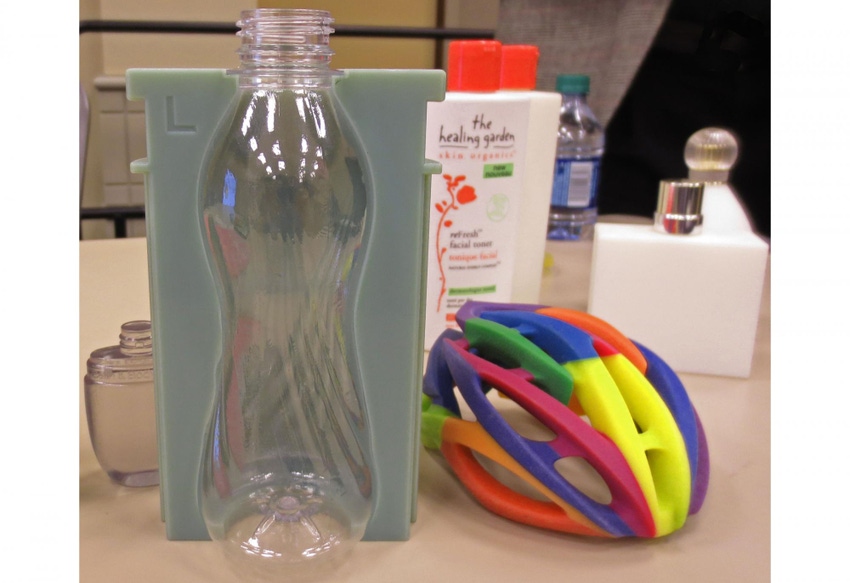

The four 3D printing “buckets” applicable for packaging are concept models, functional prototypes, manufacturing tools and end-use parts;

He wryly characterized Stratasys’s Fused Deposition Model (FDM) extrusion technique as a “sophisticated hot-glue gun” that’s easy to use and offers a real thermoplastic, though it yields a porous, rough-surfaced object.

The technology can be used in packaging to create molds for blow molding, injection molding and thermoforming.

“The sweet spot for 3D printing is where the complexity of the object to be printed is high and the volume is low,” he said.

Brand owner and vendor users

Macfie cited companies that were using 3D printing for packaging:

The Dial Corp.’s 3D printing groups use the technology to develop home-care products focused on packaging where it helps to communicate concepts accurately.

Silgan Plastics used 3D printing to speed the development of the snap-fit lid for the spoonable container version of Truvia sweetener and helped cut the lead time for that process from 30 days to 2 days.

Xerox Corp.’s application for thermoform packaging reduced costs and cut lead time both by more than 90%.

Thermoformer Tray-Pak creates nearly all of its molds using 3D printing and gets 1,200 to 1,500 parts from a printed mold. The time to produce customer samples is reduced from 3-6 weeks to 1-2 days.

Other customers include brand owners Estee Lauder, Coty, L’Oreal, GlaxoSmithKline and Mondelez and vendors GenPak, Lombardi Plastic and Smart Design Co.

For more information, visit Cimquest.

You May Also Like