Keeping cool with case printing, stretch wrapping

January 29, 2014

The recognized leader in insulated lunchboxes and, by most measures, in the soft-sided cooler market, Chicago-based Outer Circle Products, Ltd. has made its name by keeping things cool under heated conditions. But, when unmanageable raw-material inventory procedures and insufficient stretch-wrapping capabilities caused temperatures to rise at its Cicero, IL, assembly and packaging plant, the company had to look to outside suppliers to put out the fires.

Offering a line of approximately 60 products, comprised of nearly 300 active stockkeeping units, Outer Circle markets a full range of insulated storage containers–including everything from lunch bags and boxes to bottles, jugs and gallon containers, as well as children's toy chests and other miscellaneous items–under the Arctic Zone brand name. Licensed products for private-label use are also manufactured and packaged by the company.

The company's Cicero plant services major retail stores, including Kmart, Wal-Mart, Target and others. In the spring and summer months preceding the back-to-school season, when insulated lunchbox buying is at its peak, the 450,000-sq-ft plant may be staffed with up to 500 employees working two shifts. During off-season months, staff requirements taper down to 54 full-time employees over one shift. Either way, with so many skus being readied for so many customers, speed and efficiency are critical.

Today, after its acquisition of a digital case printer from Iconotech to replace the use of preprinted shipping cases, as well as the purchase of a fully automated pallet stretch wrapper from Lantech for speedier unitizing, Outer Circle is meeting those requirements better than ever.

Preprinted cases lack flexibility

Despite its prodigious output, Outer Circle's Cicero facility boasts relatively few bells and whistles, beyond its state-of-the-art printing and stretch-wrapping capabilities. Most other operations are manual.

|

|

|

The digital case printer's magazine, far left, accommodates case blanks up to 36 x 39 in., in stacks up to 39 in. high. After being printed, cases exit onto a restacker, middle photo, and are then fed onto a conveyor. The printing plate, or 'stencil,' right, is designed on a Windows-based PC and printed on a thermal imager. Plate loading is semi-automatic; plate unloading is automatic. |

Finished soft goods, manufactured in China, arrive at the facility by the truckload. The insulated items, which are shipped flat to maximize space during transport, then proceed through the facility's assembly operation, where packaging or marketing materials, such as tags or promotions, are added. The shelf-ready products are then packed in shipping cases, which are manually stacked on pallets.

In the past, Outer Circle relied on preprinted cases to convey pertinent identifying information. But what they found was that not only was this a cost-prohibitive method due to the expenses incurred with offset printing, but it also wreaked havoc with the company's raw-material inventory accuracy. "It forced us into buying a lot more different case skus," says Dale Bailey, in charge of warehousing and logistics, operations, for Outer Circle. "For example, we might use the same size case for several different products, having different item numbers. Therefore, they each would require their own preprinted case, so our inventory of boxes was really out of control. We had too many cases.

"With too many cases, it's harder to maintain your inventory accuracy and to keep track of your demand versus your supply," he continues.

In some instances, when a product would change from a promotional to a non-promotional item, or vice versa, and would require a new item number, operators would use an Intermec printer to create p-s labels that would be placed over the old information. Explains Jason Jellovitz, responsible for Outer Circle's production, this loss of flexibility was another pitfall of using preprinted cases. "Even though we were using preprinted cartons, we'd have to label over the preprinted information anyway," he says. "You're not going to throw the carton away, because it's the same size carton, same product, but now the item has changed." This method also compromised the appearance of the cases, Jellovitz adds.

Inventory, quality issues eased

In late '99, after a particularly difficult year battling inventory-accuracy issues, Outer Circle's management sought a solution that could reduce case skus, while maintaining critical numerical information on the shippers. They chose the DCP-3200 digital case printer from Iconotech, which would allow them to print the cases in-house as needed.

|

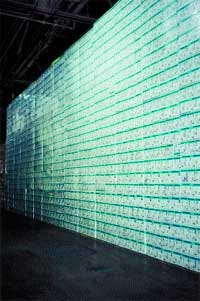

A new automatic straddle stretch wrapper lets Outer Circle build pallets to maximize shipping and storage cubes. |

With the DCP-3200, say Bailey and Jellovitz, Outer Circle can now print cases comparable in quality to preprinted stock, but at a greater cost savings. The single-color printer, which provides an 11 x 23-in. print area, can produce 60 cases/min at 200 dpi. Notes Bailey, "It's really hard to distinguish the cases from those that are preprinted. The bar codes are completely scannable."

A pruned inventory of case sizes now comprises 21 skus, ranging in size from 0.4 cu ft to 3.6 cu ft. Information added to the RSCs includes any graphics or logos; item numbers, which, Bailey says, "drive the company's whole internal production and shipping processes"; and bar-code information printed per the customers' specifications. Cases are printed in one pass on two adjacent panels; four-panel printing, which is not required by Outer Circle, involves two passes through the machine.

Recouping its investment in the DCP in one year, Outer Circle is now saving up to $100,000/year through "cost-avoidance," says Bailey. "We've been able to reduce our headcount slightly. But the biggest cost savings have come from not having to pay for platemaking, a reduced inventory and the purchasing power gained through bulk buying of plain cases," he says.

With the DCP-3200, plates, or "stencils," are output directly from a Windows-based computer to a thermal imager. Loaded on the DCP in a matter of 11/2 min, the plates can be used for up to 5,000 impressions. And, as the registration is set during the image-creation process, no machine adjustment is required.

Printing stock on-demand also ensures that cases do not become obsolete. "We have a 99.96 percent inventory accuracy with our raw materials," says Bailey. "I can tell you that our accuracy prior to having the digital case printer was significantly lower. While there were some other issues that we had to address to become better organized, the printer clearly helped us with our case inventory."

Stretch wrapper maximizes efficiencies

Next in line (literally) for an overhaul was Outer Circle's stretch-wrapping equipment. The semi-automated Lantech Q-600 turntable stretch wrapper, used to unitize all of the company's products, was incapable of keeping up with the necessary throughput speeds and demanded too much operator attention. Says Jellovitz, "When we encountered a bottleneck, our operators would have to manually wrap the pallets with eighteen-inch film to eliminate the pressure on the system. This method was cost-prohibitive, since labor is always a significant cost and the process of manually applying film is more expensive and provides a less-effective wrap than that achieved with a machine."

After learning about Lantech's fully automated straddle stretch-wrapping offerings at Pack Expo '00, Outer Circle purchased an S-3503 S-Seriese from the supplier and installed it the following February. "Its speed and its ability to wrap tall loads were the two main features we desired," says Jellovitz. "In addition, the automated conveying system used to move pallets to and from the machine was also very appealing."

|

Now having a more efficient stretch wrap, pallet loads are stacked up to three loads high, maximizing storage capacity. |

The machine, controlled by an Allen-Bradley PLC, offers a production speed of up to 35 rpm and provides Outer Circle with a maximum load size of 40 x 48 x 90 in, which enables the company to build pallets to maximize its shipping and storage cubes. "With this equipment, we can more easily build our pallets up to ninety inches tall, which allows us to use the maximum amount of height possible for shipping inside a shipping trailer," explains Jellovitz. "Since our product is not heavy enough to weigh out a trailer, we need to cube it out to attain our efficiencies."

Providing a more efficient wrap, the new equipment has also enabled the company to modify its warehousing model. Pallets have been eliminated for storage purposes, and loads are now clamped by a forklift and are stacked three-loads high, rather than two, throughout the warehouse. "We still have to ship to our customers on pallets," says Jellovitz, "however, we add those into the process as we build the loads for our customers."

Conveyors set controlled pace

Along with the stretch wrapper, Lantech supplied the Cicero facility with powered infeed and exit conveyors, along with a transfer table that allows pallets to be turned 90 degrees without being reoriented. Conveyors feed the stretch wrapper according to information provided by photoeyes along the line. "It is a simple supply-and-demand principle guided by sensors that dictate whether a section of conveyor needs a supply," explains Jellovitz.

The conveyors, he says, also enable a "paced exit," which allows the forklift operators to be more effective and efficient in their removal of loads from the system. "We have been able to eliminate two forklift operators and one general laborer since we acquired the system," he adds.

The stretch wrapper also offers several unique features that Jellovitz says "make the system more reliable and easier to operate." Among them is the Power Roller-Stretchw PLUS film delivery system, which provides a 250-percent pre-stretch; the Reachw arm with an impulsed hot-wire film cutter; positive wipe-down; the E-Z Threade roll carriage; and Auto Film Cut-offe. The system comes standard with an Allen-Bradley programmable logic controller.

As successful an installation as Outer Circle's previous acquisition, the DCP, the S-3503 also paid for itself within one year, says Jellovitz. According to Lantech's website, the price range for this unit is $62,900 to $90,000. Now that's a lot of lunch money!

More information is available:

Printers: Intermec Technologies Corp., 800/347-2636. Circle No. 217.

Digital case printer: Iconotech, 800/521-0194. Circle No. 218.

Stretch wrapper: Lantech, Inc., 800/866-0322. Circle No. 219.

PLC: Allen-Bradley, 414/382-2000. Circle No. 220.

About the Author(s)

You May Also Like