Packing haircolor cartons with poise

January 29, 2014

|

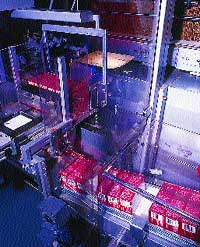

As cartons of haircolor feed into the case packer's upstacker, above, another of the new side-loading case packers is opening and squaring a case, below. |

|

Beauty isn't merely skin deep at L'Oréal USA. With revenues in '00 of more than $3 billion overall, the New York City-based U.S. arm of L'Oréal Paris pays strict attention to every cosmetic detail, as is demonstrated by the packaging equipment for its large line of retail haircolor products. The world leader in cosmetics is also on the cutting edge of haircolor processing technology, manufacturing numerous retail haircolor products it sells worldwide.

There are streams of retail haircolor formulations available in practically every retail supermarket and drugstore chain in North America, so L'Oréal's U.S. production facilities must be well equipped to meet what appears to be a permanent wave of consumer demand. After all, as the company points out in its ads, consumers are "worth it."

A key factor in the efficient haircolor kit cartoning/casing/palletizing operation located within its 300,000-sq-ft packaging operation in Clark, NJ, is a series of end-of-line casing/palletizing equipment built in France by Cermex. This includes an SB27 side-loading case-packing system and a pneumatically driven, four-axis P741 palletizer. The case packer side-loads one-piece corrugated RSC shippers in a 2 x 2 x 1 configuration with 12 cartons of haircolor. Oriented in the shipping cases top-up, the cartons are first bundled in three-packs?grouped in stretch-film bands to secure them during transport.

Currently devoted to packaging a variety of retail haircolor products, including its massive and prestigious Preferencew line as well as Garnier's Lumia,e a relatively recent introduction, and a very new low-ammonia permanent color gel called Open,e the plant in Clark handles products for distribution covering North America. The plant has come to standardize on both Cermex systems.

The compact, balcony-style design of the case packer was a factor in the plant's decision to continue purchasing this model, says Ed Saar, manufacturing engineering manager. Saar says the lower-level case magazine facilitates loading while user-friendly guards on the machine offer easy access to components. Able to reach speeds of 13.5 cases/min, the belt-driven unit also has an elevating/lowering stacker and a cantilevered case-transfer mechanism that accommodates even the most fragile of corrugated case materials.

|

Cases, far left, exit the case packer's integral tape sealer and convey to the infeed of the palletizer, above right. Cases are first uprighted by a tipping device. The palletizer's mechanical loading arm, above left, grips two cases at a time for pallet loading, as incoming cases are staged. |

The plant was impressed, and has so far purchased eight of them as part of the company's ongoing equipment upgrade program. Saar tells PD that four end-of-line systems were installed on new haircolor lines added last year, and at least four are so far being added this year.

In the first quarter of '01, L'Oréal installed a packaging line that runs cartons of Garnier products, including Lumia, that are equipped with one of the new side-loading case-packing systems and the P741 palletizer. The following October, the plant added another line that runs some of the company's many Preference haircolor products. This is also outfitted with a set of the same Cermex end-of-line equipment models. Says Saar, "As with any manufacturing operation, space is limited, so we wanted compact equipment because we have so many lines. We researched case-packing equipment for most of 2000 and looked at several, but we chose the Cermex machine. We have different generations of the P741 palletizer throughout the operation here. The majority of our current lines running the haircolor kits have some version of the P741 palletizer on them."

Also built in France, the P741 features X, Y, Z rotation of the picking head. Key advantages are a compact layout and flexibility of the pallet patterns it can handle, according to Cermex. The P741 typically stacks and layers the sealed cases in one of two pallet patterns, depending on the cartons and cases being unitized, before the loads are stretch-wrapped for shipment. With programmable pick-and-place operation and pallet-presence sensing, the system is designed to palletize loads for L' Oréal at speeds up to 7.5 cases/min.

These new end-of-line packaging machines join other Cermex end-of-line case-packing/palletizing combinations the plant has installed or will soon install in the packaging operation in Clark.

Saar says that compared with other lines at the plant, the new lines reach slightly higher packing speeds, from a rate of 4 to 5 shippers/min to 8.5 cases/min. In addition, several shrink wrappers were also replaced. The lines now feature new Pester PEWO Model 250 stretch-bundling equipment that unitizes the cartons in three-pack bundles, enclosed in clear film bands.

The SB27 is also being adopted on these lines due to the manner in which the haircolor cartons are positioned inside each case, Saar adds. "Side loaders are a cost-efficient solution, and we already had side loaders so we wanted to stay with that type of case packing. The Cermex machines are reliable and fit into a lot of the things we want. The open, easy-access balcony design is easier to clean than other machines and impressed us, so we began specifying the same case packer for new lines being or to be installed," he says. "The ergonomic equipment packs the existing cartons and cases more efficiently than could be done previously. Also, the machines have the ability to handle the various shipper dimensions we use. We sought equipment solutions that had the efficiency, ease of operation and flexibility we need to package all of the haircolor cartons in RSC cases as usual, but we wanted equipment that could handle any additional case configurations we may use in the future," Saar tells PD.

Many of the plant's haircolor cartoning lines include upstream equipment from various vendors. Two that were running L'Oréal's Preference and Garnier Lumia products during PD's visit both feature the SB27 and P741 end-of-line packing/palletizing systems and similar equipment upstream, including the new stretch bundlers from Pester and conveyors from Flexlink.

All of the U-shaped haircolor kit lines usually run three eight-hour shifts a day, five days a week.

Cartoning, casing

Located in different rooms, the Garnier and Preference lines PD visited pack about 50 cartons/min and load them with bottles and/or tubes of haircolor as well as instructional literature and packets of conditioner. After the haircolor kits are cartoned, the cartons convey on a straightline single-lane belt conveyor away from the cartoners and make a right turn toward the case packers.

|

Catons make a right turn out of the cartoner on one of L'Oréal-Clark's many U-shaped lines and heads to a checkweigher before being case-packed. |

Just before they proceed, they move toward a checkweighing system from Hi-Speed that checks each carton for the proper contents, among other features, and clears the cartons for bundling on the Pester stretch bundler. If the filled cartons don't meet specifications, they're kicked off-line by a rejection arm. Once cartons are collated, they're cross-fed into the wrapping station and banded tightly with clear film (from several sources). Oriented top-up for casing, they then convey about 10 ft to the SB27 case-packing system.

The SB27 consists of a bundle infeed, an upstacker/collator, a belt conveyor, a carton-detection system, a case erector, side-loading/folding sections and tape-sealing, case-discharge and tipping sections. Monitoring the case packer is an Allen-Bradley SLC 504 programmable logic control with a Panel View 100 color touchscreen that displays machine layout.

Batches of carton bundles convey into the belt-driven case-packing machine with their short sides leading and are transferred on rollers to an upstacker via a pushing arm. The infeed then moves backwards, which separates the bundles being stacked.

Meanwhile, the shipping case blanks, many of which are made of 200#-test, B-flute single-wall corrugated, provided by proprietary sources, are extracted from an extended case-blank magazine 59 in. in length that holds about 20 minutes' worth of flat cases (depending on the thickness of the case). To better promote ergonomics for operators on the lines, the loading height of the angled case-blank magazine is always the same, regardless of case configuration.

A rotating arm equipped with suction cups pulls the blank open and places it into the case-forming section.

After a sensor detects that a case has been extracted, a second mechnical arm forms the case while another set of suction cups holds one panel of the case for squaring.

As the carton bundles feed into the upstacker and are detected by a pair of sensors, a mechanical pusher arm uprights them in batches of two after rows to be stacked have been detected. A pusher then ensures lateral transfer of the bundles into the open-ended case as sensors count out carton bundles in groups of four. The bundles are packed into the case in a 2x2x1 configuration.

Flap folding

As a sensor detects that the case is formed, a loading funnel and rotating bridge hold case flaps while the carton bundles move upright into the case, pushed by a mechanical arm for loading inside the case. Case flaps are then broken and closed, and the funnel enters the case momentarily to secure the flaps.

While the products are being uploaded, the loading pusher stroke is checked by the PLC prior to returning to its original position. Pusher arms move the opened case over flap-folders that close the leading and trailing flaps. The minor case flaps are tucked in to act as an end stop for the cartoned, bundled products. Next, two hinged bars prefold or break the top major flaps, and a shuttle carrier transfers the case to the next station where major flaps are folded.

While the products are being uploaded, the loading pusher stroke is checked by the PLC prior to returning to its original position. Pusher arms move the opened case over flap-folders that close the leading and trailing flaps. The minor case flaps are tucked in to act as an end stop for the cartoned, bundled products. Next, two hinged bars prefold or break the top major flaps, and a shuttle carrier transfers the case to the next station where major flaps are folded.

Major case flaps are folded down progressively by two fixed guides on either side. Tape is applied by an integral taping system. The packer is also available with a hot-melt adhesive applicator, but most of L'Oréal's packing machines are set up for taping. The case packer can also accommodate many other packaging configurations beyond the 2 x 2 x 1 configuration to a shipper, but "that's the company's main configuration," Saar explains. "We also don't have to take advantage of that very often because we don't require a lot of package/product changeovers, and in the case of the end-of-line machines, we don't change them over at all, so we order them with the minimum of changeparts," he says.

|

New bundler, above, collates haircolor carton kits into groups of three and stretch-bands each group. |

And, Saar says, while changeovers aren't as much of an issue for L'Oréal's mostly dedicated packaging lines, the SB27 packer can be quickly changed over with mechanical adjustments. Cermex tells PD these include adjustment of the motorized, extended case-blank magazine and pusher arms for upstacking and batch loading, as well as the transfer funnel that ensures the products are inserted into the case. Selection from the PLC controls of a new case program, and a simple switch of changeparts, and the mechanical adjustments can take approximately 10 minutes.

Uprighted and palletized

Once the cases are filled and sealed, they discharge on their sides onto a free roller of a case-tipping device. A sensor detects that the case is being tipped 90 degrees, upright, ready for palletizing. Before the cases reach the palletizer, however, they're ink-jet-coded on each long side with a 14-digit bar code, haircolor shade and other product descriptions, as well as a date and lot code. Although other haircolor packaging lines in the plant are equipped with coders from other sources, the ink-jet systems in place on these two lines are provided by Foxjet.

|

Cases eject from integral taper to be bar-coded with product information, date and lot codes, and descriptions. |

Since infeed and outfeed of empty and full pallets is performed manually on these lines, the pneumatic palletizer is equipped with a light beacon and message display unit that signals the line's operator of the need for a pallet changeover. With a positive product infeed, conveyor buffer, custom suction-cup gripping tooling, and lateral guides and retractable stops at the gripping station, the system receives cases on a Cermex roller conveyor. The cases feed in lengthways and are loaded on the pallet with the short side of the case leading. Sensors on either side of the system activate the four-axis mechanical arm and gripping and turning head. The suction gripper then picks up the cases one by one or in pairs and places them onto a 40 x 48-in. pallet, depending on the pack pattern.

The machine typically layers 15 cases per layer, six layers per load, for a total of 90 cases/pallet.

The palletizing arm continues to pick and place cases, per PLC programming of the pallet-packing pattern, until a full palletload of haircolor cases is complete. From there, the loads are forklifted off-line or staged by operators using hand trucks and are stretch-wrapped on machines from ITW Mima before they're transferred to an offsite warehouse location prior to distribution, in order to furnish just-in-time delivery for customers, Saar tells PD.

Additional benefits, plans

By standardizing on end-of-line machines, L'Oréal has been able to increase productivity and improve ergonomics. It also sees added production flexibility, and operators like the access to machine components as a result of better ergonomics.

|

Palletizer in action, above, uses a four-axis mechanical arm and suction gripper to pick and place cases, typically layering 15 cases per layer, six layers per load. |

"We're very impressed with these Cermex systems," Saar says. "They operate smoothly. The equipment always arrives on time, and it's well engineered." He says the plant should see a return on its equipment investment on end-of-line casing and palletizing equipment that meets L'Oréal's aggressive targets for captial expenditures."

Saar says additional haircolor packing lines are already in the works for the Clark plant.

More information is available:

End-of-line case packers, palletizers: Cermex, Inc., 678/221-3570. Circle No. 268.

PLCs: Allen-Bradley Co., 440/646-5000. Circle No. 269.

Stretch-bundling equipment: Pester USA, Inc., 201/347-7009. Circle No. 270.

Conveyors: Flexlink Systems, Inc., 610/954-7000. Circle No. 271.

Checkweighers: Hi-Speed Checkweigher Co., Inc., 800/836-0836. Circle No. 272.

Ink-jet coders: Foxjet, an ITW co., 817/795-6056. Circle No. 273.

Stretch wrappers: ITW Mima, 954/724-7788. Circle No. 274.

About the Author(s)

You May Also Like