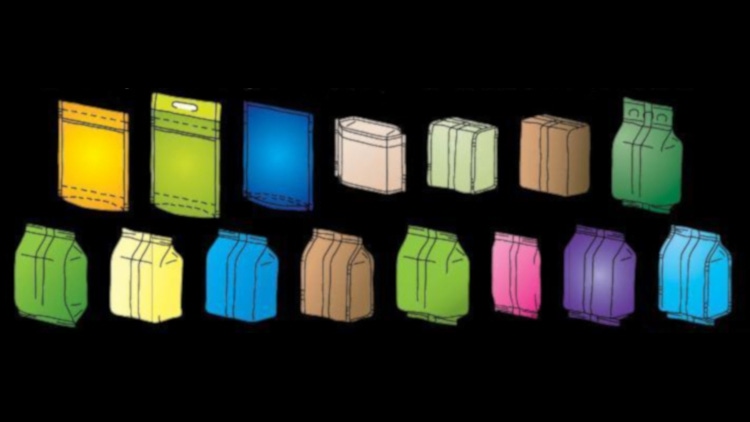

Vertical baggers can juggle many package formats now

Today’s shopper expects multiple choices—in products and in type of packaging. That’s one of the reasons a brand’s number of stock-keeping units is exploding. And with flexible packaging continuing to encroach on rigid containers in several categories, the demands of versatility and speedy changeover for machines that make these packages are high.

In response, vertical form-fill-seal (vffs) equipment designs are evolving to meet the expanding operational and marketing challenges of packagers that use this type of equipment. The latest vffs machines can run numerous flexible-packaging formats, with fast changeover, for example.

User requirements for improved uptime, line efficiency, sustainability, waste reduction, sanitary machine design and operator-friendliness are also driving equipment vffs advancements. Read what vffs experts have to say about all the trends in the exclusive Packaging Digest Q&A below. The participants are:

• Dennis Calamusa, president/CEO at AlliedFlex Technologies Inc. (the exclusive Velteko distributor for North and South America);

• John Panaseny, CEO of Rovema North America Inc.;

• Kim Magon-Haller, marketing manager, Triangle Package Machinery Co.;

• Shayne De la Force, chief marketing officer at tna solutions Pty Ltd.;

What recent advancements have there been in vertical form-fill-seal systems?

Calamusa: I can think of four developments.

1. Versatility of design: This provides versatility in package size and package format.

Over the past few years, we have seen a growing trend by prominent vffs producers to implement advanced technology in the design platform of their vffs machinery to enable users to better respond to market changes in package size and package format. This is being accomplished in a variety of ways.

Velteko, a prominent global vffs manufacturer, has approached this challenge by “re-designing from the ground up” a series of its vffs machinery by utilizing a group of quick-change modules that make the major mechanical changes from one bag format to another much simpler and repeatable. This design breakthrough has enabled a user to perform three-dimensional package format changes within 5 to 45 minutes for a multitude of bag styles, including pillow, quad and stand-up/zipper, depending on the complexity of the changeover. This innovative, versatile design strategy provides the ability for a single machine to accommodate changes in package size and package style. That is critical for companies to respond to marketing shifts for a variety of market outlets, including single-portion sizes, retail sizes and larger clubstore and foodservice sizes.

The Velteko HSV-360 B vffs system can package food and non-food items and accepts a variety of bag formats, including stand-up/zipper pouches. Photo courtesy of Velteko.

2. Ultrasonic sealing:The use of ultrasonic sealing in vffs machinery is growing as companies look to improve seal integrity and minimize package size. Ultrasonic technology is also being used to perform improved “zipper crush,” now that zipper reclosability is a popular and growing convenience feature on vffs machinery.

3. Servo technology/operator interface:Most advanced, quality vffs machines today have replaced many mechanical components with servo motors, which provide improved flexibility and reduced maintenance compared with older mechanical-drive systems. These servo systems have enabled the machines to be run with a high level of flexibility to accommodate a multitude of operational improvements that positively impact productivity, efficiency, higher output and reduced cost of ownership.

The operator interface provides recipe storage for a multitude of package setups to reduce on-site service calls.

In addition, with the ability to incorporate advanced sensing devices, we can now provide more detailed real-time information regarding productivity, downtime and even predictive maintenance, which is valuable for production planning and packaging-system optimization.

4. Automatic roll change/splice:Many companies are looking to increase uptime. This is particularly important on vffs machinery, as it is popular to have several machines grouped as part of a turnkey system [to produce enough volume for downstream equipment, like case packers, that run at higher speeds]. Downtime is a cost, and even short-interval downtimes can negatively impact productivity, efficiency and product/packaging-material waste. Many vffs companies and users are investing in the addition of semi-automatic and automatic roll change/splicing systems to keep the machine up and running and eliminate these consistent short-interval stoppages for performing manual roll changes, which cause lost production and increased material scrap. These systems can be provided fully integrated or added later, in the field.

Panaseny: The biggest advancements have been in two key areas. The first is in bagger flexibility. In the past few years, machines have been developed to offer a dramatic array of package styles, from traditional, simple pillow bags to the more complex Doyen-style stand-up bags with reclosable zipper that can be produced at relatively high speeds on continuous-motion equipment. (The Rovema BVC260 Flex Bagger is an example of this.) Although vffs machines that could handle the bag styles existed previously, the newer technology produces much better looking bags and at higher rates of speed.

The Rovema BVC-260 Flexible is a continuous-motion vertical bagger that can provide virtually any package style, including Doyen-style stand-up bags (RoPack).

The second area of advancement is in machine reliability and repeatability. As consumer packaged goods companies (CPGs) struggle with employee retention, machinery that helps with changeovers as well as troubleshooting problems is becoming the norm. In both cases, much of the advancement is tied to technology in motion control and human machine interfaces (HMIs), which make these features easier to execute and more affordable for manufacturers to produce.

Magon-Haller: The advancements we’re seeing—and the areas we’re continuing to focus on—include versatility, sanitation and operator-friendly machines. In the past, most companies were simply looking to run a specific bag style. In recent years, there is more uncertainty over which way markets are moving, which leads companies to search out more versatile vffs solutions that are capable of running multiple bag styles.

Our Model XYRJ, for instance, features a unique, rotatable sealing jaw that allows users to run pillow-style bags, three-sided seal bags, gusseted bags and a stand-up pouch (SUP). It’s also the only vffs bagger that offers an optional longitudinal zipper and/or transverse zipper on the same machine. We developed Model XYRJ because we knew many of our customers and potential customers wanted a bagging machine that was versatile, easy to use and able to run a variety of bag styles on the same machine. The bagger allows food packagers to improve production and switch package formats in just minutes.

Many advancements have also been made in the area of sanitation. The majority of Triangle’s customers are in the food industry, so sanitary machine design is an important consideration. A bagging machine that’s easier to clean not only saves cleaning and maintenance time but also offers peace of mind to companies that may otherwise be worrying about how to minimize consumer complaints and avoid product recalls.

Sanitary machine design is one area where we have proactively researched and answered customer needs. Our decades of experience operating in the harshest environments has also proven to be of value in other markets. Over the years, sanitary design of our vffs baggers has improved to reduce hazardous critical control points, crevices and the use of aluminum. We offer the only bagger and forming tube that is 3A-certified and meets strict United States Department of Agriculture (USDA) sanitation standards.

For example, our recently introduced Compact Sanitary Bagger, Model CSB, offers state-of-the-art sanitation features such as rounded, solid stainless-steel frames and is designed to be cleaned in place.

In addition, many advancements make vffs baggers easier to operate and maintain. With more companies struggling to find qualified labor, operator-friendly machines can go a long way to address these challenges. We strive to build certain features into our baggers that will shorten the learning curve and minimize downtime. These include, for instance, features that offer tool-less, quick-and-easy changeover, HMIs with built-in visual instructions and radio-frequency identification (RFID) technology to restrict machine access and monitor usage.

De la Force: More and more, manufacturers are focusing on sustainable practices in manufacturing, hence working on reducing waste, boosting efficiency and making user interfaces easier for operators of vertical form-fill-seal systems; this equally applies to all other aspects of food packaging and manufacturing, as well. Reducing food waste not only helps the bottom line of the manufacturer, it also helps in boosting line efficiency.

Waste reduction with increased packaging speed (popularly measured as bags per minute, or just bpm) is the combined metric for evaluating the vffs system, and this is where packaging- and processing-solutions providers are pioneering and innovating.

Another key direction of innovation is automation and integration, where the whole packaging system and its allied components—like multihead weighers, metal detectors, date coders and more—work as one unit controlled through a single user interface. Intuitive and easy-to-use touchscreen control makes operations quicker, easier and more efficient.

How do these advanced systems compare to the existing standard equipment?

De la Force: Key achievements of the advanced systems in recent times are: reduced human effort, lower waste, reduced downtimes and stoppages, higher OEE and overall better sustainable operation. As with any development, the rollout and results are not visible overnight. It is a gradual and ongoing process in which the packaging-machine manufacturers are supporting the food manufacturers in upgrading their systems through backward compatibility and system design support so they can make the most of these advancements. Customers (food manufacturers) are seeking solution providers as compared to machine suppliers.

Magon-Haller: The bottom line is, various advancements—improved sanitation, more versatile machines and operator-friendly baggers—offer similar but important benefits, such as minimized downtime and improved production.

Baggers that offer quick changeover and ease of use spend a lot more time churning out bags than sitting idle while an operator tries to perform complicated changeovers.

Baggers that offers more sanitary designs and better accessibility to the machine are easier and faster to clean and maintain. Our stainless-steel guard doors, for instance, are more sanitary than standard doors, but their unique design with perforated holes still allows visibility of the machine operating.

All Triangle bagging machines offer state-of-the-art sanitation features and can be designed to meet strict 3-A and USDA sanitation standards. Pictured is Triangle’s Model XYM15 vffs bagger, with optional stainless-steel guard doors.

In addition to cleaner machine designs, our baggers include features that offer greater machine accessibility, such as a pivoting control box for four sides of machine access.

Panaseny: A large portion of the vffs install base is older and therefore built at a time when mechanical devices (cams, gears and so on) controlled machine motions rather than programmable electronic servo motors. Additionally, just as computing technology evolves rapidly, a similar impact is felt with packaging-machinery controls. The result is more capabilities in machine monitoring, HMI capabilities and improved overall equipment efficiency (OEE) by using technology to monitor, correct and assist with operations.

Calamusa: Many existing or older machines do not have advanced capabilities, as many vffs machines delivered over the past two decades did not need to meet the evolving market demands of today—or the technology did not exist. Many older machines were purchased and installed for dedicated bag styles and applications, and were not designed with the changeover, production demands or operational philosophy required today.

What are the benefits of these advancements for packaging machinery buyers/users?

Panaseny: The new developments assist with operational challenges tied to a tight labor market with high employee turnover. The more the equipment can be easily operated and maintained, the better the performance the buyer/user will experience.

De la Force: By running more efficiently with lower waste, packaging-machinery users are achieving higher return on investment (ROI). At the same time, users are achieving higher levels of sustainability, and with the reduction in human effort through technology and innovation, the working environment is positively evolving in this industry sector.

Calamusa: Marketing departments are always challenged to introduce “what’s next,” and this is very difficult when they know that changes at the manufacturing level are usually frowned upon.

By investing in new, versatile vffs machinery, manufacturing can now be more responsive to the needs of the organization and better adapt to change by being part of the solution and creating new business opportunities for the company. The ability for the user’s manufacturing/packaging department to say “yes” to its marketing department is a very valuable and refreshing concept in today’s competitive business landscape.

Magon-Haller: In addition to less time spent on cleaning and maintenance, the benefits of a more sanitary machine include peace of mind and greater accessibility to equipment. Customers can rest assured they are making a wise investment and that critical issues—such as accessible equipment and clean machine designs—have been addressed.

A more versatile bagger that can run multiple bag styles on the same machine also provides a smaller capital investment. Why buy two machines when you can purchase one that has the flexibility to run pillow bags, gusseted bags, stand-up pouches and three-sided seal pouches? As resealable packages continue to gain popularity, finding a bagger with the ability to add a longitudinal and/or transverse zipper applicator can also be a smart investment.

What areas in vertical form-fill-seal equipment still need work and why?

Calamusa: We are seeing a demand for all packaging machinery, including vffs machinery, to be more sanitary in design. This is not only a requirement for packaging frozen or refrigerated products, but also when packaging dry or dusty products. The ability to properly sanitize and clean the equipment is critical to prevent the risk of dangerous bacteria and allergens contaminating or cross-contaminating packaged foods. Downtime attributed to cleaning and sanitation is substantial, and improved sanitary design by the vffs manufacturer is highly appreciated and demanded by today’s packagers.

Panaseny: We’ll need to see continued evolution of equipment that can provide self-diagnostics and that can be monitored remotely to support a workforce with fewer troubleshooting skills.

What’s next, and when might we see further improvements in vertical form-fill-seal systems?

Calamusa: Work continues by forward-looking vffs manufacturers to validate the handling and running of new “sustainability” materials, including recyclable, composable and biodegradable structures. These thinner, more elastic materials can be challenging regarding critical temperature sensitivity, tension and web-handling challenges, package aesthetics and so forth; however, the packaging machinery industry and consumer product companies are all committed to this challenge, and we can expect to see considerable effort to resolve these challenges in the coming months and years.

Panaseny: I think you will see more advancements in sealing technology to support new materials that address sustainability concerns, and continued development with respect to internet of things (IoT) or Industry 4.0. Some industries are quite advanced in this area, but I think that packaging and vffs equipment are still in the early stages of adoption.

De la Force: Stand-up and resealable bag formats, biodegradable materials and personalization will continue to further drive vffs technology in the future, meaning that there will be changes to how films are handled and sealed and changes to packaging shapes and sizes—and all developments will need to keep up with the trends.

Magon-Haller: Packaging-machinery customers are looking for machines that are both compact and operator-friendly, as well as accessible and easy to maintain. We will continue to develop vffs systems that are compact, versatile and innovative—for instance, vffs machines that offer a compact footprint and high output in terms of both speed and package-style variety. Package styles will always be evolving, and we’ll continue to work with customers and suppliers to provide machines that can run the next style.

The tna robag FX-series system offers high speeds for vffs applications.

____________________________________________________________________________________________

MinnPack 2019 (Oct. 23-24; Minneapolis) is where serious packaging professionals find technologies, education and connections needed to thrive in today’s advanced manufacturing community. See solutions in labeling, food packaging, package design and beyond. Attend free expert-led sessions at multiple theaters around the expo.

About the Author(s)

You May Also Like