Salad dressing shows its curves

Glenn Brooks started Georgia Intl. Foods (GIF) as a contract packager more than 20 years ago and started Classic Signature Foods about 12 years ago to market to airlines a line

ga beauty.jpg

of salad dressings and other food products that he had developed. In 2008, Brooks entered the retail salad dressing market with a distinctively shaped 17-fl-oz patented bottle combined with a spectacular shrink-sleeve label. Brooks felt the distinctive bottle and label were crucial to success in the competitive retail salad dressing market to attract as much attention as possible.

"Being a small company and playing with the big boys, we had to do it right," says Brooks. "You can have the best product in the world sitting on a shelf, but no one's going to buy it unless they've used it, seen it in a commercial or it looks so good that it's got to be good."

The custom, patented Classic Signature bottles, which are supplied by CKS Packaging Inc., are certainly different than the typical flask or cylindrical bottles that pourable dressings are normally found in. They are shorter and much more curved than those bottles, have a 48-mm finish and are made from PVC instead of PET or glass.

The shrink-sleeve labels, which are supplied by Sleeveco Inc., are made of PETG and are rotogravure printed in up to seven colors. The label extends over the cap to provide tamper evidence and has perforations beneath the cap so that the cap can be removed easily. Brooks specifically wanted the full-sleeve label with its vibrant, eye-catching graphics, to make the product stand out.

Shrink labeling

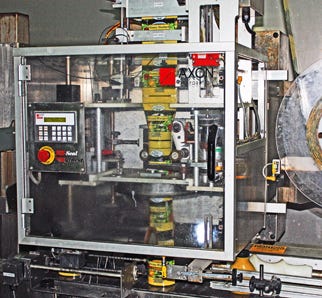

To run the new bottles, Brooks installed a new

ga labeler.jpg

packaging line. He purchased an Axon EZ-SEAL 200SL shrink label/tamper-evident applicator and an Axon steam heat tunnel because he says that Axon Corp., a div. of Pro Mach, offered the most value. The EZ-SEAL 200SL can achieve a production rate of about 220 bottles/min.

In this operation, film is pulled from a roll mounted on the back of the machine by a motorized film unwind system that ensures that the film-delivery system located inside the machine has a constant supply of film that is not under tension. This helps to minimize slippage during film feeding and ensures accurate film-cut lengths.

The film travels down through a film-dancer system, where it is looped through a film weight on a slide. As the machine advances the film, the weight is pulled upward, which triggers a sensor that alerts the unwind to pull more film off of the roll and into the dancer system, causing the weight to drop. When the weight drops below the sensor, the unwind stops feeding film.

Next, the film travels into the sleeve-application chamber, where it passes through a series of guide rollers and is then pulled

ga filler.jpg

over the mandrel that opens the tubular film. In this operation, two stepper-driven rollers work in conjunction with the print-registration system to ensure that the correct length of film is advanced. The print-registration system, which uses an Allen-Bradley fiberoptic system from Rockwell Automation, is located at the top of the film mandrel and includes both vertical and horizontal adjustments.

When a detection photoeye senses the container, multiple blades located around the mandrel cut the film, which is then advanced down the mandrel by the following label. Finally, the cut sleeve is pushed down onto the container by the film-application rollers located at the base of the mandrel.

The labeled bottles travel through an Axon model EZ-120-SS steam tunnel to shrink the labels onto the bottles. "The labeler is doing a good job for us, and Axon was excellent to work with," says Brooks.

14-head piston fillerGIF installed a 14-head rebuilt piston filler from Elmar Industries Inc. to fill the dressings. "We bring our rebuilt machines up to our new-machine standards, and it's a considerable cost savings for our customers," says Elmar president Mark Dahlquist.

The rebuild for GIF included new inverter-controlled motors, a no-container/no-fill system that stops the piston movement in a fill head if a bottle is not present, a container gate stop that enables the operator to interrupt bottle infeed to the unit at a touch of a button on the HMI.

It also includes a new electronic control system featuring an Allen-Bradley PLC and HMI from Rockwell Automation.

The filler has a maximum output of about 140/bottles/min.

Bottles are metered into the starwheel of the filler by a feedscrew from Morrison Container Handling Solutions and are placed on individual plates. Product is contained in an overhead tank, and the pistons suck it into the cylinders and then discharge the product into the bottles as the machine rotates.

The bottles discharge tangentially onto the conveyor and are transported through a Computorque automatic inline belt capping machine from Inline Filling Systems Inc. that mounts over the conveyor.

The machine uses a unique patented cap tightening system of rotating belts rather than spindles and features pneumatic cap torque control for accuracy and reduction of scuffed caps. It also includes on-demand operation in which the machine only operates when containers enter the capping zone.

The bottles then enter the Axon labeler and shrink tunnel described previously. As the bottles leave the shrink tunnel, they pass an Excel 2000 inkjet printer from Videojet Technologies Inc. that applies a code date and lot code. Bottles are manually hand loaded onto the infeed conveyor and manually case packed after capping.

"When you have a small company and limited promotional budget, innovative graphics and packaging, in this instance bottle shape and label, can even the playing field," says Brooks. "I'm very pleased with the way this project has worked out."

More information is available:

Axon Corp., a div. of Pro Mach, 919/772-8383. www.axoncorp.com

Elmar Industries Inc., 716/681-5650. www.elmarworldwide.com

CKS Packaging Inc. 404/691-8900. www.ckspackaging.com

Inline Filling Systems Inc., 941/486-8800. www.fillers.com

Morrison Container Handling Solutions, 708/756-6660. www.morrison-chs.com

Rockwell Automation, 414/382-2000. www.rockwellautomation.com

Sleeveco Inc., 706/216-3110. www.sleeveco.com

Videojet Technologies Inc., 800/843-3610. www.videojet.com

About the Author(s)

You May Also Like