Can slack-fill law drive sustainability in packaging?

Public awareness about slack fill is on the rise and laws that publicize significant slack fill fines or penalties are now on the books. How can brands right-size their packaging in the product development cycle?

Slack fill. Sounds like a made-up phrase, right? Trust me, it’s real. It’s so real that it has legal implications, and many consumer packaged goods (CPG) companies and food manufacturers are learning about slack fill the hard way.

Slack fill is the difference between the actual capacity of a container and the volume of the product it contains. Is slack fill often an ethical dilemma? Yes, it is.

And educated consumers are pushing back on consumer goods manufacturers who are using deceitful packaging to dupe them into thinking they are buying more than they actually are. That’s why class action lawsuits are on the rise.

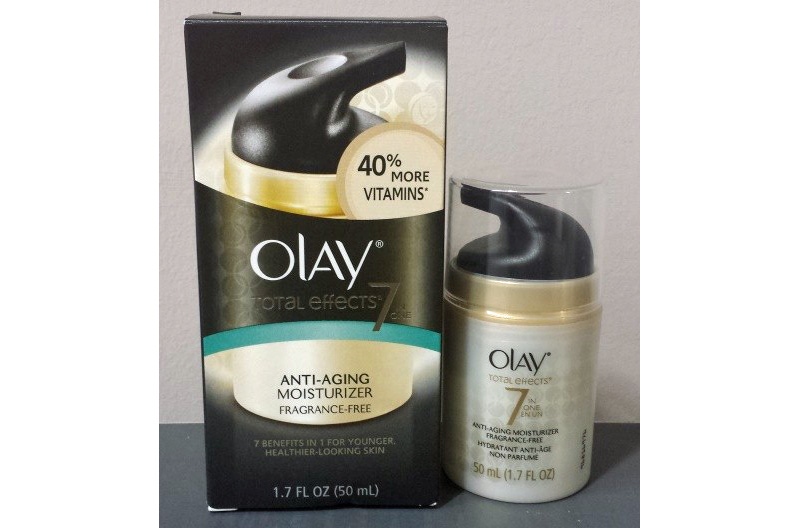

Typical blatant slack fill law violations usually come from food manufacturers and the pharmaceutical and health and beauty industries--where the rules clearly state no use of false-side walls, which were used for years inside cartons to make the product appear bigger on the shelf than it actually was.

P&G paid $850,000 in civil penalties and fines to settle this slack fill incident. Upon opening this pack, this is what you would see: A small primary pack containing the product with false side walls built into the carton to make the product appear larger than it actually is.

Recent packaged products flagged for potential slack fill violation

Many large CPG companies have had class action suits brought against them for slack fill in one or more product categories, with typical published settlements ranging from $40,000 to over $250,000.

Some of the more-famous companies in the slack fill gallery of rogues include McCormick Spice, which attempted to remain price competitive by selling three ounces of pepper. No problem, right? Well, in this case there was a problem, as they were selling the three ounces of pepper tin in the exact same old 4-ounce tin. This means the 3oz tin was now roughly one-third empty!

This type of activity--commonly referred to as “weight-out” or “package to price”--is an exercise companies undertake to sneakily reduce the amount of product they’re selling in order to maintain the same price point. They assume consumers won’t notice this sleight-of-hand change.

But whatever you call it, putting less product in the same size (or larger) package is a blatant slack-fill violation that even the best attorneys will have a difficult time defending.

Why reducing slack fill is a better approach to savings and improved sustainability

Once you know what slack fill is, it’s almost impossible to walk down the aisle at the grocery store and not see packaged products that deliberately or inadvertently incorporate possible nonfunctional slack fill.

For many CPG’s, food manufacturers and even co-packers that produce tens of thousands, if not millions of packages per year, package size requirements can be a balancing act. It’s often the packaging engineer’s job to walk the fine line between meeting the key success criteria for all stakeholders, since:

Marketing wants a large graphics billboard to make their product stand out on the shelf.

Operations wants larger packages, so they can run equipment a top-end speeds and minimize filling issues and change-overs.

Legal counsel wants right-sized packaging to eliminate nonfunctional slack fill (and avoid settlement fees or slack fill penalties).

Most packages on the shelf today are optimally sized. Many have sufficient air space in them, so that the “reasonable man” would expect to open the package and find it contains a reasonable amount of slack fill.

But make no mistake: There are still some packages that contain nonfunctional slack fill.

In these cases, it pays to think like a packaging engineer! Think of the improved sustainability, and the reduction in packaging materials if each of these companies were to truly optimize their packaging and improve their ratio of product vs. packaging. Using less materials, reducing costs, and reducing slack fill risk all in one shot: Sounds like a win, win to me!

Rob Kaszubowski is the Engineering Manager at Chainalytics, where he is focused on improving sustainability metrics and implementing packaging cost savings while leading a team of packaging consultants. Rob also contributes to the Packaging Matters blog.

Connect with Rob on LinkedIn and on Twitter @KazPack1

___________________________________________________________________________________

Want to get ideas on how to optimize your packaging? You’ll find options for that and more at MinnPack 2016 (Sept. 21-22; Minneapolis). Use discount code PDigest16 to get 20% off your conference registration.

___________________________________________________________________________________

About the Author(s)

You May Also Like