How to Choose Ink for

Improved Sustainability

January 30, 2014

|

There is increasing pressure today for product manufacturers to be environmentally friendly, or sustainable, in both the processes and products produced. More than ever, the questions of how to achieve sustainability goals and what it will cost are top-of-mind for facility owners and managers who are simultaneously handling the responsibilities required to run a plant efficiently and economically.

There are multiple ways manufacturers can become more sustainable, from using less material in their packaging to employing plastic alternatives, such as biopolymers, to streamlining distribution channels in an effort to reduce emissions of delivery vehicles.

Achieving more sustainable processes and products can be a gradual process for some companies, particularly due to budgetary constraints and the evolution of product packaging.

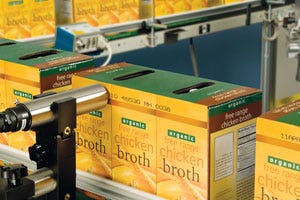

It can be a pressure-filled task, particularly if an internal, corporate, “green” mandate has just been handed down. An area that's receiving increasing attention by consumer product goods (CPG) manufacturers seeking to increase sustainability is the inks used to print variable-data codes on primary and secondary packaging.

Shifting to more sustainable, variable-data inks can be an important element of an overall “green” strategy; in fact, they can be a logical starting point, because of their relative ease of implementation.

More sustainable inks that can reduce the amount of volatile organic and synthetic compounds entering the atmosphere and the waste stream are becoming available. Variable-data printer ink is made up of three basic components:

dye, or a code's colorant

resin, which makes the ink (and, therefore, a code) adhere to the packaging substrate or the product itself

solvent, which can be viewed as a “carrier” of both the dye and resin, and is crucial to facilitating the application process

Many chemicals can be used as a solvent, including acetone, methanol, cyclohexanone, methylethylketone (MEK) and ethanol. There are also inks that use water as a carrier.

The chemical content, particularly the carrier, makes some variable-data inks more sustainable than others. The benefits of shifting to more sustainable, variable-data inks can be substantial for product manufacturers, particularly in the area of cost savings. Depending on the ink selected, cost savings may be found in handling, waste disposal, personal protective equipment, permitting, reporting and record-keeping.

Sustainability defined

|

Perhaps the first significant challenge for product manufacturers that seek to develop more sustainable manufacturing processes and products is actually defining the terms “sustainability” and “green,” which, to a great degree, are used interchangeably today. Sustainability is often viewed as an actionable term intended to produce specific, meaningful results. For example, a sustainability goal could be the conservation of materials, energy and labor in a manufacturing process, or a shift from current materials to more environmentally friendly alternatives, such as more sustainable variable-data inks. Conversely, “green” suggests a more strategic viewpoint—an overall initiative under which each of a manufacturer's sustainability goals fall.

A prime example of the proper usage of the terms sustainability and “green” is Walmart's Packaging Scorecard, introduced in 2006 and defined by the company as “a measurement tool that allows suppliers to evaluate themselves relative to other suppliers based on specific metrics.” Walmart suppliers receive an overall score based on nine specific criteria:

15 percent of the overall score based on greenhouse gas/CO2 per ton of production

15 percent based on material value

15 percent based on product/package ratio

15 percent based on cube utilization

10 percent based on transportation

10 percent based on recycled content

10 percent based on recovery value

5 percent based on renewable energy

5 percent based on innovation

The goal of the Packaging Scorecard is a 5-percent packaging reduction across Walmart's worldwide supply chain by 2013, making it a sustainability component of its overall “green” mission. But the underlying intent of the Packaging Scorecard is to provide a means for Walmart suppliers to determine areas in which they are strong with regard to sustainable packaging, and also areas in which they need to improve. That, in turn, can aid suppliers in developing their own “green” strategy and sustainability goals.

Initiatives and regulations

|

|

Industry-specific and corporate-driven initiatives that have gained particular momentum both in the U.S. and Europe have forced CPG manufacturers to develop specific sustainability goals, which, in effect, have crafted their individual “green” strategies. An example of this is the International Organization for Standardization's ISO 14000 standards, an environmental-management system featuring specific requirements and guidelines a manufacturer must meet to display continual improvement regarding environmental impact. ISO 14000 provides many other benefits as well, including reduced cost of waste management and lower distribution costs.

Meeting ISO 14000 requirements and guidelines is often a comprehensive and time-consuming task for manufacturers, and requires the commitment of an entire company—from executives to line operators. An assessment of a company's variable-data printers and the inks they use can play a significant role in achieving certification and, subsequently, maintaining it.

For example, engaging printers with maximum uptime—printers that run longer between maintenance—reduces the amount of cleaning solution required to clean printheads; using less cleaning solution means fewer potential, volatile organic compounds (VOCs) entering the atmosphere.

Employing more sustainable inks, such as waterbased inks is another example.

Many major product manufacturers, particularly in the electronics industry, have instituted programs to reduce the amount of harmful chemicals used in their products that ultimately enter the wastestream. In 2001, Sony Corp. instituted its Sony Green Partner Standards, which established substances that must be controlled or eliminated by suppliers. The list includes cadmium, lead, mercury, hexavalent chromium and polychlorinated and polybrominated biphenyls (PCBs and PBBs), tributyltin and triphenyltin compounds, asbestos, formaldehyde and PVC4. Several chemicals, including lead, mercury, hexavalent chromium and cadmium, are specifically restricted from usage in packaging materials, paints and inks that affect Sony suppliers that use variable-data ink-jet printers to mark products, parts and packaging.

The Matsushita Group, parent company of Panasonic Corp., introduced its “Chemical Substances Management Rank Guidelines” in April 2006, which documents substances that are prohibited or regulated. For example, substances that cannot be intentionally used by a supplier include PCBs, paraffin chloride and polychloronaphthalene.

Other substances, like asbestos, cadmium, lead and hexavalent chromium, also cannot be intentionally used, but the total amount incidentally found in a product must be less than an established parts-per-million amount. It also specifically prohibits the use of cadmium, lead, hexavalent chromium and mercury in pigments, dyes, paints and inks.

Noncompliance with programs like those of Sony and Panasonic means that a supplier will no longer be able to sell to those companies. That can result in dire financial consequences for that supplier.

European legislation

Many of the chemicals found on the lists of controlled or prohibited substances from Sony and Panasonic specifically reference European Union (EU) laws and regulations, such as Restriction of Hazardous Substances (RoHS).

RoHS is a mandatory EU regulation that focuses on electrical and electronic products and related components, and limits the total amount of six specific chemicals in a product: cadmium; mercury; lead; hexavalent chromium; PBB; and polybrominated diphenyl ethers (PBDE). An electronics manufacturer exporting products to Europe needs to control these chemicals in the materials and components that make up its products, everything from motherboards to circuit breakers to inks used to mark the products.

Noncompliant companies run the risk of fines and possibly an EU importation ban. Thus, confirming with a supplier of variable-data printers that its inks are RoHS-compliant—and requesting documentation of that fact—is one way to protect against such risks, and can help ensure compliance with manufacturers' programs.

Another key piece of EU legislation is the End-of-Life Vehicles (ELV) initiative, which eliminates use of lead, mercury, cadmium and hexavalent chromium in both automobiles and their parts, and establishes specific targets regarding parts that can be recovered, recycled and reused, which limits the impact on the European wastestream. This is similar to the Waste Electrical and Electronic Equipment (WEEE) directive, which became EU law with RoHS in February 2003. WEEE establishes targets for recycling and recovery of electrical products, and also limits the impact on the European wastestream.

The choice of variable-data inks will aid in compliance with both directives, but can also help meet recovery, recycling and reuse targets. Like RoHS, noncompliance with both ELV and WEEE runs the risk of fines and an EU importation ban.

Another set of guidelines comes from the European Printing Ink Association (EuPIA), a division of the European Council of Paint, Printing Ink and Artists' Colours Industry (CEPE). CEPE is an EU organization that has published its own list of ingredients that it recommends should not be used in inks; among them are solvents like methanol, certain dyes and other chemicals.

It is a set of voluntary guidelines, meaning the EU cannot enforce it, but it still has influence. A company can choose not to purchase any product that is not compliant with EuPIA guidelines. Thus, noncompliance can negatively impact sales.

The Registration, Evaluation and Authorisation of Chemicals (REACH) program regulates all chemicals produced within or imported by the EU, including the chemicals found in packaging.

To produce or import a product, a manufacturer must provide adequate toxicological and physical hazard documentation regarding the chemicals contained within, which includes variable-data inks printed on the package. As with RoHS, noncompliance means that manufacturers wouldn't be allowed to market their products in EU member states.

U.S. legislation

In the U.S., product manufacturer “green” strategies, comprising specific sustainability goals, are typically driven by customer requirements, such as those of Walmart, Sony, Panasonic and many others. Apple Computers has promoted an initiative to remove toxic chemicals from its products, including lead, hexavalent chromium and mercury10.

The Coalition of Northeastern Governors (CONEG), comprising several northeastern U.S. states, has developed a model rule called the Toxics in Packaging Legislation, that regulates usage of four chemicals that could be found in certain packaging, including the variable-data inks on the package: lead; cadmium; mercury; and hexavalent chromium. It sets a maximum amount of the sum of those four chemicals at 100 parts/million. The Toxics in Packaging Legislation was drafted for states to use as a basis to create their own laws, and has been implemented in more than 20 states. If products are sold into a state that has adopted its own version of the legislation, the products must be compliant. Noncompliance means that a manufacturer runs the risk of fines or other legal action.

Another example of increasing U.S. legislation is the South Coast Air Quality Management District (SCAQMD), the air pollution control agency for California's Orange County, located south of Los Angeles. Rule 1171 of the SCAQMD rule book, titled “Solvent Cleaning Operations,” is designed to decrease emissions of VOCs and toxic-air contaminants. It specifically addresses the cleaning of ink-jet printers, capping the amount of VOCs for package printing at 0.21 lb/gal. Minimizing the use of cleaning solutions such as those used on the printheads of variable-data ink-jet printers reduces the amount of VOCs entering the atmosphere, producing exposure to workers.

In adddition, the U.S. Environmental Protection Agency pollutant emissions regulations are individually adopted by each state and are considered a baseline for their laws; thus, state laws can be more stringent than federal regulations but cannot be less stringent.

There are various levels of allowable emissions within regulations set by the EPA, but as levels progress, a manufacturer faces new and more intensive reporting processes, including more permits to fill out and submit. Often, manufacturers are concerned to learn that emissions have crossed a level threshold and will immediately search for ways to reduce emissions.

These solutions often add cost—everything from hiring personnel to overseeing the added permitting and paperwork to purchasing emissions-control measures like filters, burners or washing stations.

'Green' strategy

Requirements, guidelines and regulations regarding the prohibition or stringent control of hazardous substances, whether industry-driven or legislative, are a few reasons a product manufacturer develops specific sustainability goals, such as shifting to more sustainable inks. Those goals can help a manufacturer achieve a “green” strategy and positive public perception that it's making products safe for consumers, employees and the environment.

A “green” strategy can create a competitive advantage in the marketplace as well. Specific sustainability goals can be leveraged by a manufacturer to earn new business from both current customers and prospects. Also, it can be used in consumer-marketing efforts to differentiate products from the competition, which can translate to increased sales as consumers feel more comfortable about the products they purchase.

The number of requirements, guidelines and regulations might seem onerous for a product manufacturer to meet, but they provide opportunities in which to differentiate products and processes from competitors and provide value to customers by helping them meet their sustainability goals.

Opportunities with inks

It might not seem that the inks within a variable-data printer on a production line can have much impact on making a manufacturer and its facility more sustainable. But a package's composition includes the ink, and that influences recycling options. There is a growing trend for managing packaging waste, called “cradle to cradle,” that strives to have a product's packaging recycled and reused, making that package more sustainable. But to do that, the manufacturer must know exactly what comprises a package before it enters the supply chain. Some [package printing] inks are even formulated for more seamless removal during the later manufacturing or recycling process.

Suppliers might help manufacturers find ways to improve employee safety by changing inks. Assessing the needs for inks can result in shifting to an ink with fewer VOCs or one that is intrinsically “safer,” which reduces the exposure of such compounds. Some printer suppliers can perform VOC emissions estimates based on consumption rates of equipment. But a supplier may also be able to consult on other improvements, such as moving a printer to a different location on a production line to reduce worker exposure to VOCs.

Getting started

Many manufacturers realize the importance of developing a “green” strategy with specific sustainability goals. Typical concerns include determining what the goals mean for their operation and how to get started. One step would be to contact suppliers to assess printers, inks and application specifics. Chances are, the suppliers will be able to provide recommendations on the most effective changes to make.

Tapping into that information can make the path to implementing a “green” strategy simpler and less cost-intensive. Regardless, the relative ease in which “greener” inks can be incorporated will likely aid in the development of an environmentally responsible initiative.

You May Also Like