It’s time for bioplastics to be plastics

August 6, 2019

“I wish people would stop calling PLA* a bioplastic…” said Steve Davies, director of public affairs and communications at NatureWorks during a recent meeting of the Sustainable Packaging Coalition’s Industry Leadership Committee on Bioplastics. “…and start thinking of it as one more functional material—dare I say it…another plastic.”

These words were spoken by a representative from one of the largest producers of bioplastics in the world—in fact, one of the chief pioneers in the field and the reason the word “bioplastics” is as ubiquitous as it is today. Steve’s point is this: When those of us in the packaging community hear the word “plastic,” we think of a spectrum of polymers with different performance characteristics, costs, sustainability attributes, advantages and disadvantages. But the word “bioplastic” often carries a narrow connotation of a compostable, plant-based plastic with limited functionality and prohibitive cost.

It’s time for that to change.

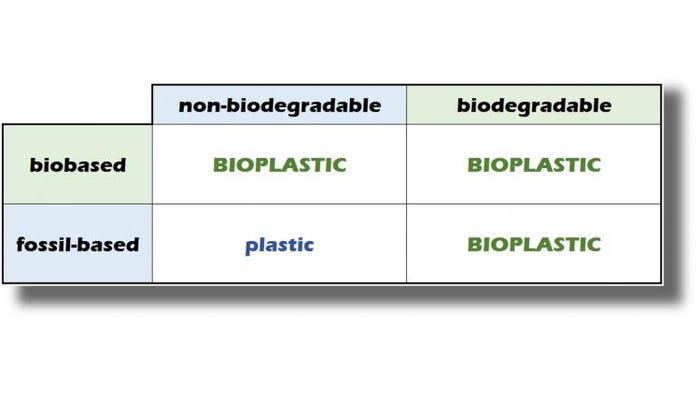

The world of bioplastics has exploded, and there is an amazing breadth of materials that can be classified as bioplastics. Part of the reason, arguably, is the far-reaching definition of a bioplastic. The most commonly used definition, popularized by European Bioplastics, is that a bioplastic is bio-based, biodegradable or both. To unpack this, that means that a bioplastic can be inherently non-biodegradable. It means that a bioplastic can contain 0% bio-based materials. A bioplastic may be 100% fossil-based. It can be any combination of being partially bio-based, fully bio-based, non-bio-based, biodegradable, compostable or non-biodegradable, so long as it is not both non-bio-based and non-biodegradable.

There are four basic permutations of these characteristics, and bioplastics encompass three of them:

The definition of bioplastics is a matter of semantics, but the semantics are removed when the family of bioplastics becomes enveloped in our definition of plastics. There are a slew of terms used when describing plastics: “barrier plastic,” “formable plastic,” “heat-resistant plastic.” By including the terms “bio-based plastic,” “biodegradable plastic” and “compostable plastic,” we can articulate more clearly what properties are relevant to our conversations.

For those companies interested in decoupling plastics from fossil-based feedstocks, as is encouraged in the Ellen MacArthur Foundation’s New Plastics Economy initiative, “bioplastics” may or may not be the answer. “Bio-based plastics” are the answer—and it’s also important to recognize the importance of partially bio-based plastics, as the world of bio-based intermediates is ballooning and partially bio-based plastics can keep that innovation marching forward.

Here’s another point to consider: Amazing work is being done to pursue plastics made from sequestered atmospheric greenhouse gasses. This technology carries the promise of decoupling plastic from its conventional fossil-fuel feedstock, but it doesn’t fit the common definition of a bioplastic. Semantics strike again, and to advance the use of novel feedstocks, we can’t limit ourselves to “bioplastics.”

Other companies are interested in compostable plastics. For packaging likely to end up with food waste, compostability is especially enticing. It offers an alternative to recycling, which is phobic of contamination, and diverts food waste from the landfill by delivering it to the industrial composter who can take advantage of its residual value.

For this pursuit, “bioplastics” may or may not be the answer. One step further, “biodegradable plastics” may or may not be the answer either, since not all biodegradable plastics are truly compostable. “Compostable plastics” are the answer, and the matter of the feedstock being bio-based, partially bio-based or fossil-based, is not directly relevant to the job the plastic is being hired to do.

So rather than the binary distinction between plastics and bioplastics, let’s simply expand the list of functional characteristics on the polymer specification sheet. Buyers of plastics should continue to choose resins for their combination of functional material characteristics and cost performance.

But let’s marry the family of PLA*, PEF*, bio-based PE*, modified starch, PHA*, and many others with the family of PET*, fossil-based PE*, PP*, PS* and everything between to recognize that “bioplastics” are equally—if not more—diverse than the conventional family of plastics, and the functional characteristics related to feedstock and end-of-life compatibility are neither mutually exclusive nor limited to an outdated understanding of uniquely progressive materials in our growing world of packaging.

Adam Gendell is the associate director of GreenBlue’s flagship project, the Sustainable Packaging Coalition. His work with the packaging value chain touches on goal-setting, design considerations and stakeholder engagement. Gendell has developed and delivered training seminars for hundreds of packaging professionals, including the coalition’s fall conference: SPC Advance. He coordinates several Industry Leadership Committees and is a frequent speaker and writer on sustainability topics. In 2013, Adam served on the PAC NEXT Leadership Council.

*Abbreviations:

PE—polyethylene

PEF—polyethylene furanoate

PET—polyester

PHA—polyhydroxy alkanoates

PLA—polylactic acid

PP—polypropylene

PS—polystyrene

******************************************************************************

Learn what it takes to innovate in the packaging space at the new Advanced Design & Manufacturing Cleveland event (Mar. 29-30; Cleveland, OH). Register today!

You May Also Like