There’s still a need for speed in cartoning

April 24, 2017

In the pharmaceutical industry, there’s been much discussion about lot sizes shrinking and the need to accommodate quick package changeover. But while this trend has deepened, another years-long trend continues—the growing demand for generic drugs and commodity products. So, while flexible, quick-changeover packaging lines are in demand for small-volume products, the industry also needs higher-speed systems to support burgeoning generics demand.

"Oral solid dose applications are trending towards more generic, long-run, commodity campaigns. As such, they are necessitating solutions that drive cost efficiencies," Daryl Madeira, director, business development at Körber Medipak Systems AG, tells PMP News. "A better utilization of manufacturing operations supports this need. Having said this, customers do not want to compromise the changeover and cGMP benefits that they have come to appreciate from Mediseal."

In addition, "parenteral applications, meanwhile, are trending toward less caregiver interaction," Madeira continues. "This is driving therapies from multi-count to single-count packaging. But the volume of therapies have not dropped and thus there is a need for high-speed cartoning to manage the same demand in single-count packaging."

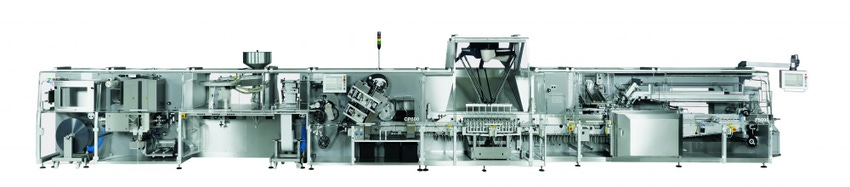

Mediseal is supporting these trends with packaging machinery options to meet needs for flexibility and speed. At Interpack, the company will be introducing the P5000 high-speed cartoner for high-speed blister packaging lines. With a 120-mm separation, 500 cartons per minute are possible, with a maximum folding box size of 90 x 110 x 200 mm. And with 180-mm separation, available as a machine variant, cartons with dimensions up to 150 x 110 x 200 mm can be filled at speeds of up to 300 cartons per minute.

"In numerous discussions, we were hearing that our customers have a need for even faster cartoners,“ said Borja Guerra, Mediseal's sales and marketing manager, in a news release. "With the P5000 high-speed cartoner, we now offer the right solution for our high-speed blister machines."

So Mediseal widened its portfolio to extend from highly flexible systems such as the "White Line" system for custom printing blisters, leaflets, and cartons to high-speed cartoners. The company based the P5000 on the platform and components of its established P3200 cartoner.

“What makes the Mediseal solution novel is the ability to transfer all valued functions of our lower-speed, intermittent cartoner to this higher-speed continuous cartoner,“ Madeira reports. “For example, to support higher speeds, a stronger force is required to feed the carton contents, but we do this without any increased force against the product. This ensures that the customer’s product is kept safe throughout the process. In addition, in keeping with Mediseal’s design vision of maintaining the ultimate in operational flexibility, the P5000 continuous cartoner uniquely offers an extended format range.“

Madeira says that there are a few challenges when operating at high speeds, so Mediseal leveraged its proprietary expertise to overcome them. “One example is what we described above – we have developed a method for feeding the carton contents without increased force against the product. Relative to feeding, it is key that one is able to feed product to the product cell chain to keep up with the cartoning speed – this is a unique strong point from Körber Medipak businesses, leveraging intelligence from Dividella and Fargo Automation. A final example would be in the area of cGMP. High-speed packaging is quite prevalent in segments such as food and beverage, but doing this for a highly regulated segment such as pharma is quite another story. Mediseal has perfected features to ensure a clean, open cartoning process so that cGMP is never a concern at any speed.“

For example, for such cGMP compliance, “we have achieved this by virtue of features such as maintaining easy-access from the front and back and by articulating each carton just prior to grabbing for carton erection. These features are also maintained on the new P5000.“

And quick changeover is still possible. “Mediseal is the industry leader in small-lot, quick-changeover,“ Madeira says. “We have achieved this by virtue of features such as automatic carton height adjustment and digital changeover handwheels directly tied to the HMI. These features are maintained on the new P5000 to ensure quick changeover is not compromised at high speeds."

Lot codes, expiration dates, and serial numbers can all be added at high speeds. “All print and verify requirements, including those for Track and Trace, can be achieved with the P5000,” he says.

The primary drivers for the P5000 cartoner are pharma oral solid dose and parenteral applications, but medical device applications could benefit, too, Madeira says. “For example, medical device applications such as insulin pens or asthma inhalers are also moving towards large volume, long run, generic applications, similar to oral solid dose, and thus a high-speed cartoner will allow for these trends.“

Madeira believes that the P5000 will continue to meet the needs of pharma (and medical) companies for the next 5 or 10 years. “As the therapies recently launched continue to be successful, volumes will grow by virtue of patient demand and generic uptake. This is true for oral solid dose and for parenteral applications. The P5000 will position pharma companies well to support this growth.”

The P5000 cartoner will be in operation along with the CP600 high-speed blister machine at two upcoming shows: Interpack 2017 in Düsseldorf (Hall 16 Booth A25) and at FCE Pharma in Sao Paulo, Brazil (Booth 721).

About the Author(s)

You May Also Like