Stylish shrink-sleeve label fits tiny bottle

January 29, 2014

|

Capable of reaching speeds of 750 ft/min, the eight-station gravure press runs at an average speed of 500 ft/min for the Three Olives labels. |

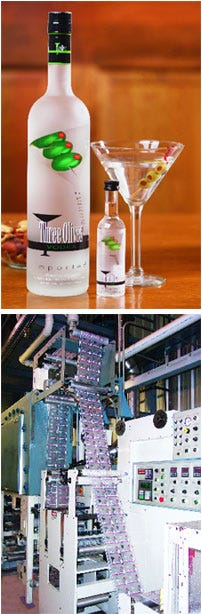

In 1999, White Rock Distilleries, Lewiston, ME, unveiled Three Olives vodka in a "cool" frosted-glass bottle that displays a clear outline of a martini glass located on the bottle's front. The clear martini-glass window provides a see-through effect to an olives graphic on the back of the bottle. The unique bottle design strives to reinforce the brand's image of an upscale product and also to differentiate the vodka brand in a crowded distilled spirits aisle.

The frosted glass bottle is produced in Europe and is imported to White Rock Distilleries, where it is packaged and distributed nationally. Three Olives product offerings come in 50-, 375- and 750-mL and 1- and 1.75-L sizes. The initial U.S. rollout included the five bottle sizes using the decorated, frosted glass bottles from Europe.

However, White Rock released six flavored vodkas under the Three Olives name in 2003 and needed to look for alternatives for a smaller, 50-mL size. "Reduced costs is a major factor in using shrink-sleeve labels versus the frosted glass bottle," says Scott Coulombe, plant manager, White Rock Distilleries. SleeveCo prints and converts the 2-mil polyvinyl chloride shrink-sleeve film for White Rock. Bonset America provides the single-layer film.

Coulombe adds, "Besides costs, the availability of the acid-etched bottle from Europe was difficult, and the shrink-sleeve labels offer flexibility with inventory. Now, we can stop on a dime and change our production schedule to package the vanilla vodka flavor, instead of waiting for the delivery of the frosted bottles from Europe." White Rock uses the shrink-sleeve labels for all of the 50-mL vodka lines, but still uses the frosted glass bottles for the larger sizes.

A frosty feel

For the flavored vodka rollout in 2003, White Rock released three vodkas–raspberry, vanilla and chocolate–using 50-mL frosted glass bottles from Europe. Shortly after the flavored-vodka release, SleeveCo began the R&D process for using shrink-sleeve labels to achieve the acid-etched look of the larger bottles. Martin Wilson, director of marketing and sales, SleeveCo, says, "Typical matte finishes come across too cloudy, and we needed to get pop, depth and definition for the labels. Working closely with our ink supplier, we continually modified the formulation of the ink."

Also, once the film is on-press, curing agents and solvents are used to alter the matte finish to achieve the desired look. For the first run of label printing, SleeveCo produced three different variations, and White Rock chose the best representation of the frosted bottle, PD is told.

The film is gravure-printed using eight colors, including varnishes, for all of the flavored vodkas and for the original line. Gravure printing proved to be the best method to portray a frosted or etched-glass look, PD is told. Solvent-based inks are used for the label printing.

SleeveCo uses an eight-station, 16-in. Chesnut 150 press, supplied by W.R. Chesnut Engineering. The gravure press includes a management information system that reduces setup time for repeat jobs, which helps greatly with the Three Olives flavored vodka labels. Capable of reaching speeds of 750 ft/min, the Chesnut 150 runs at an average speed of 500 ft/min for the vodka labels.

|

The press utilizes a management-information system that reduces setup time for repeat jobs. The film is gravure-printed in eight colors, including varnishes, for all of the flavored vodkas and the original line. |

Besides reproducing the frosted or matte finish for the shrink-sleeve labels, SleeveCo also replicates all of the other visual aspects from the original bottle. One of those aspects is the printing at the bottom of the bottle's front side. For the original bottle, the Three Olives name is overprinted onto the acid etching. On the 50-mL bottles, the matte finish is knocked-out behind the type to give contrast and to create more "pop," which offers a look similar to the larger bottles.

"Registration issues are crucial with these labels," Wilson says. "The tight dropout area mandates pinpoint accuracy throughout the run." The other major challenge is the focal point of the Three Olives' bottles–the clear martini glass "window." This window provides a see-through effect to the olives and the fruit graphics that are printed on the back of the label.

"One thing that is really important to White Rock is the ability to take the martini-glass window and have the olives and fruit visually pop off the label," says Wilson. "We're able to produce this by using a high-clarity film and running an extra layer of varnish on the label."

The shrink-sleeve labels are applied by White Rock Distilleries, which uses an Axon EZ-100 shrink-sleeve machine.

One thing leads to another

R&D for the printing of the Three Olives labels began with a previous job for SleeveCo. The company worked with a cosmetics customer to develop a matte finish with clear film, and the Three Olives project was a continuation of this application. "We performed three to six months of R&D for the cosmetic application," Wilson says. "We used the knowledge gained from this project and applied it to Three Olives to develop the frosted film look. This took an additional three months of R&D to complete. We're hoping this application will feed into other projects down the road."

More information is available:

Label converting: SleeveCo, Inc., 706/216-3110. www.sleeveco.com. Circle No. 221.

PVC film: Bonset America Corp., 336/375-0234. www.bonset.com. Circle No. 222.

Gravure press: W.R. Chesnut Engineering, Inc., 973/227-6995. www.chesnuteng.com. Circle No. 223.

Labeler: Axon Corp., 800/598-8601. www.axoncorp.com. Circle No. 224.

You May Also Like