Which of these new packaging products are the most innovative?

We need your expertise! You will decide which of these eight new products being shown at the upcoming EastPack 2016 show will earn an Innovation Award. Pick the winners by reading through these descriptions and then voting for your favorite.

Products appear here in alphabetical order by company name. VOTE HERE.

We'll let you know who the winners are as we get closer to the show, which will be June 14-16 in New York City.

Robotic case packer gains flexibility with 3D vision picking technology

Case packer with Delta pick-and-place robotics (see photo above) uses new 3D camera technology to accurately detect the shape of products on a conveyor, allowing it to flexibly handle items previously hard-to-pick for 2D vision systems—such as shiny, unequally shaped flow packs. The company explains that the 3D camera detects everything protruding from the conveyor, from 4 to 44 millimeters. The camera then filters out the product shape for the pick-and-place robot, and detects the center of gravity and the main axis to properly pick and then pack the item in a carton or case. Users don’t have to teach the camera what to focus on. See the system in action in this 3-minute+ video and at the EastPack 2016 show. The 4‐axis Delta 3 robot gently groups and places cups, flow packs or blisters into cases or trays at speeds of 40 cases per minute (single lane) or 70 cases/min (double lane).

A+F Automation + Foerdertechnik GmbH, EastPack 2016 Booth 2649

NEXT: Distinctive duo-material visual package commands attention on shelf

Distinctive duo-material visual package commands attention on shelf

Duofold packaging combines the best attributes of clear, box-grade plastic with paperboard to produce a distinctive visual package. Combining these two dissimilar substrates allows for unique structural designs—many not possible in paperboard or plastic alone—while providing two distinctive visual, textural and tactile impressions. See this unique package in this 30-second video clip, as well as at the EastPack 2016 show.

For even greater shelf impact, any combination of offset, flexographic and/or silkscreen printing, plus foil stamping and other decorating special effects, can be applied to either the plastic or paperboard panels, or both. Plastic and paperboard components are printed and converted separately, and then assembled on efficient joining equipment to produce a one-piece carton with precise component alignment.

Duofold uses the company’s proprietary Soft Crease scoring technology, which produces uniform creases with less folding resistance, ensuring that plastic components fold precisely and have clean lines. Soft Crease scoring and precise component alignment combine to produce combination cartons that ensure efficient hand loading and/or filling on automated cartoning equipment. Duofold cartons can be designed with multiple plastic carton panels or with windows that wrap around multiple score lines, permitting far greater visibility than conventional windowed folding cartons. Additionally, rigid film adds integrity and strength, allowing for a much larger windowed area than is possible using lightweight window film. For applications requiring even greater strength (a promotional liquor carton, for example), high-quality litho-lam flute can replace traditional paperboard grades.

HLP Klearfold, EastPack 2016 Booth 3003

NEXT: Energy-efficient thermoformer uses electricity instead of pneumatic air

Energy-efficient thermoformer uses electricity instead of pneumatic air

Expanded line of e-concept machines now includes thermoforming machines that save 20% on energy compared to previous machines. The energy savings come because the compact systems use a highly efficient electrical drive instead of pneumatically driven components so no compressed air lines or cooling water are needed. An added benefit is that these machines are also easy to install and set up because they just need to be plugged in to a power supply.

Multivac Inc., EastPack 2016 Booth 3011

NEXT: Bagger with vision counting system is fast/accurate for small parts

Bagger with vision counting system is fast/accurate for small parts

A new 3D vision counting system on the company’s automatic bagger is fast and incredibly accurate for small parts such as small surgical screws and other medical devices. How does it work? The precision vision system relies on an advanced mathematical algorithm that can count bulk parts ranging in size from 0.25 inch to approximately 1 inch with counting accuracy better than 99%. According to the company, this vision counting system is more accurate and faster than conventional bulk counting systems that depend on weight, which creates a productive operation that could save labor by reassigning workers elsewhere. See the Rollbag R1275 Vision automatic bulk vision counting and bagging system in action in this 1-minute+ video, and at the EastPack show.

PAC Machinery, EastPack 2016 Booth 2921

NEXT: Reclosable carded blister securely stores extra products until time of use

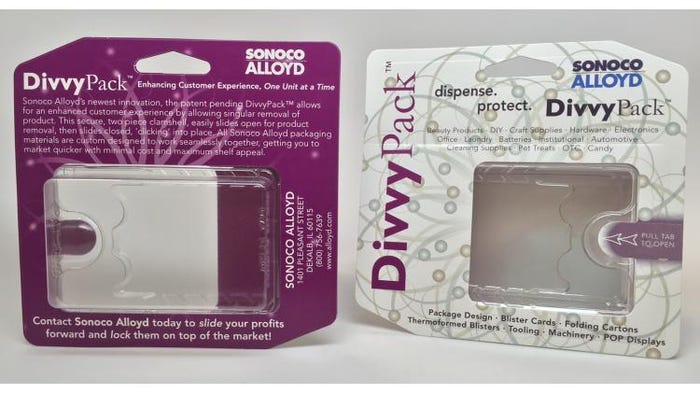

Reclosable carded blister securely stores extra products until time of use

DivvyPack carded blister recloses securely to keep product items not yet used/consumed together, which helps eliminate spills or lost or wasted product for high consumer satisfaction. The patent-pending package locks with a top lid that slides open and closed, so single products can be carefully removed. It can also be designed as a trapped blister for more security and billboard space. According to the company, DivvyPack allows products to be sold in higher volumes for higher price points. Also, because the package is used to store unused products instead of being thrown away, it helps maintain the product’s branding for the life of the products inside. This package is suitable for many types of products, such as office supplies, laundry, craft, hardware, electronics, health and beauty aids, candy, batteries, automotive, pet and cleaning supply products. See the package in this short video and in person at EastPack 2016.

Sonoco Alloyd, EastPack 2016 Booth 2807

NEXT: Dual-chamber pharma IV bag ensures exact and fast reconstitution

Dual-chamber pharma IV bag ensures exact and fast reconstitution

The new dual-chamber ready-to-administer (RTA) powder-liquid intravenous bag contains powder on the top and solvent on the bottom. Breaking the seal between the chambers safely reconstitutes the drug in the exact infusion dose prior to patient administration. With this Dual Chamber Bag (DCB), there are no risks of mixing up different powder drugs with different diluents. It also saves time for nurses doing the reconstitution in hospitals compared to the previous manual method.

Technoflex, EastPack 2016 Booth 2961

NEXT: Paper-based laminated packaging maintains its recyclability with paper

Paper-based laminated packaging maintains its recyclability with paper

New NoW (No Waste) technology makes paper-based packaging laminated with plastic able to be recycled with paper, according to the company. The materials are certified as recyclable with paper waste by SSCCP of Milan according to the standard ATICELCA 501-13 and by GreenChip Australia according to the Australian standard.

These laminations can be produced using kraft papers (white or brown) or glossy papers with different grammage depending on the performance needed for the specific request:

• Barrier laminations from 30 to 100 g/m2 with metalized plastic films such as polypropylene or polyethylene in thicknesses from 15 to 50 μm.

• Window laminations from 40 to 100 g/m2 with films such as biaxially oriented polypropylene, cast PP, polyethylene and others in thicknesses from 15 to 50 μm.

• Aluminum laminations from 30 to 80 g/m2 with aluminum foil in thicknesses from 7 to 14 μm.

Additionally, the company says that paper packaging for sugar packets can be made with kraft papers (white or brown) or glossy papers from 30 to 50 g/m2 without any plastic film lamination as a replacement for poly-coated paper packaging.

The new biodegradable paper packaging is supplied in rollstock form.

U-Packaging/BelPak Paper, EastPack 2016 Booth 3050

NEXT: Ultrasonic banding system adds capacity and improves efficiencies

Ultrasonic banding system adds capacity and improves efficiencies

The ATS US-2000 PIC-STA stacking and banding system now offers new capacity and efficiency improvements, including a glue-applicator option that maximizes efficiency by supporting the holding force between slippery products. The patented cold welding technology allows products to be banded without heat buildup or odor emissions, which is especially beneficial for packaging operations in cleanrooms. The automated system processes up to 120 products per minute and builds stack of two to 12 products of varying shapes and sizes. See the unit in operation in this 30-second video clip and at the EastPack 2016 show.

Benefits of ultrasonic sealing include instant operation (zero warm-up time); odor- and smoke-free welds that are highly durable; and infinitely variable sealing strength.

Benefits of banding include savings in materials and energy, especially compared to shrink bundling because there’s no heat tunnel required; zero product damage as the band wraps around the product; identifiable branding with preprinted bands; and easy packaging line integration with this compact unit.

Wexler Packaging Products Inc., EastPack 2016 Booth 2707

About the Author(s)

You May Also Like