12 new technologies at interpack for packaging designers

Enhanced flexible packaging, new decorating ideas, digital printing improvements and more await visitors to the largest packaging trade show in the world: interpack.

Every three years, the global packaging community is treated to a buffet of packaging innovations, technologies and ideas like no other when Messe Düsseldorf stages interpack in its complex of buildings (19, at last count) in Düsseldorf, Germany.

Open daily from 10:00 a.m. to 6:00 p.m., interpack starts on Thurs., May 4. For seven consecutive days (yes, including the weekend), packaging aficionados from around the world will search the nearly 175,000 square meters of exhibit space for new packaging ideas, solutions and technologies—that’s more than 570,000 square feet for folks not conversant in metric measurements, or about the size of five blocks in New York City.

Here’s a preview of some of the new packaging development/design-related technologies suppliers from around the world will exhibit at interpack 2017.

Page 1. Easy-open package from Mondi

Page 2. The Twist Cup from RPC Group

Page 3. A new polyester (PET) film that can be digitally printed without any need for priming or coating from Flex Films

Page 4. A new decorating process called Metallic Doming from Gallus

Page 5. New Vento coffee bag from Amcor Flexibles

Page 6. The Pharma-Multi-Act tamper-evident label for syringes from Schreiner MediPharm

Page 7. Two new co-polyamides from leading chemical and plastics company BASF

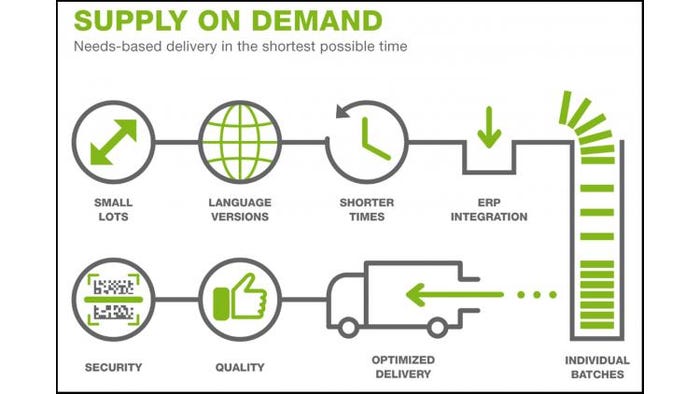

Page 8. New Supply on Demand service from pharmaceutical packaging specialist Rondo

Page 9. New near infrared-based food contaminant detection system from Sun Chemical

Page 10. New Elex-one series of electron beam (EB)-curable flexographic inks from Toyo Ink Group

Page 11. Clear, handled containers in new EPET class IV material from Bekum

Page 12. New DeltaFuze closure liner from Selig

1. In survey after survey, consumers say they want packages to be easy to open. As part of its “easy-open initiative,” international paper and packaging group Mondi offers several such solutions on its packages—CornerPack, StripePack, FlexziBox Flat Bottom with diverse features, Peel Film and ZipperPouch.

The company will showcase a recent application of its ZipperPouch, developed with renowned tea manufacturer Twinings (see photo above). With a unique structure—and new look and feel that commands attention on the shelf—this package can be easily opened and reclosed.

Mondi also collaborated on a new bio-based chocolate bar wrapper for Mars with Rodenburg Biopolymers and Taghleef Industries. The four-year development uses Taghleef’s Nativia Ness biodegradable film made with Rodenburg bio-resin and rotogravure printed by Mondi Consumer Goods Packaging. While the bio-based film runs at the same speed as biaxially oriented polypropylene on packaging lines, the printing was more challenging because the heat generated during printing could shrink the film. Arkadiusz Sapiecha, managing director of Mondi Solec in Poland where the film was printed, says, “Thanks to intensive in-house research and our long-term experience in rotogravure printing, our team was able to achieve a high-quality print which matches the appeal of standard OPP while retaining the packaging’s more natural character.”

Mondi, Hall 9, Booth A24/B23

2. Developed for Orkla Foods Norway’s line of premium cold salads, the Twist Cup from RPC Superfos and RPC Promens combines a polyethylene thermoformed cup with a polypropylene injection-molded lid—a unique, standout package for the cold salad segment. The PP lid locks into grooves on the cup with an audible click, letting consumers know the cup has been properly closed. RPC will receive a 2017 WorldStar Award at interpack for solving the technical challenges of matching two different resins and two different manufacturing technologies (thermoforming and injection molding).

RPC Group, Hall 10, Booth D21

3. A new polyester (PET) film from Flex Films has a modified surface on one side that can be digitally printed without any need for priming or coating, saving the typical steps and cost of treating the surface of films prior to printing.

The film, F-PDP, has been certified by the Rochester Institute of Technology for digital printing by HP Indigo commercial and sheet fed presses. It also exhibits optical clarity, dimensional stability, flatness and easy machinability, according to the company.

Ashok Chaturvedi, chairman and managing director of Uflex Ltd., the parent company of Flex Films, points out some of the benefits of digital printing for packaging: “Digital printing spells out immense convenience for convertors in terms of economized costs; suitability for shorter print runs; less set up time compared to offset printing; and unmatched print consistency—among others. I am happy that Uflex has engineered a special polyester substrate that is perfectly receptive for digital printing without requiring any priming, coating or special treatment.”

The company is manufacturing F-PDP digitally printable PET film in all its worldwide facilities, including the U.S.

Flex Films (Uflex), Hall 10, Booth D-44

4. A new decorating process called Metallic Doming uses rotary screen printing to create raised, metallic textures on plastic containers, such as bottles and tubes (laminated, polyethylene or polypropylene). Previously, this decorating effect was only possible by using hot-foil embossing on paper packages.

Gallus (in a joint booth with Heidelberg), Hall 13, Booth D75/E82

5. New Vento coffee bag from Amcor Flexibles provides degassing without a hard valve or extra processing steps. Additionally, the film runs on existing filling machines, with no equipment investment required.

With built-in venting, this package allows coffee manufacturers to pack ground coffee or whole beans immediately after roasting to preserve the product’s best taste and aroma. And, by moving the venting to the back of the pack, brand owners can improve the product’s shelf appeal.

The package was test-piloted by six different customers to prove out the concept and generate real results. Among the benefits were less downtime and less production waste. For example, according to Amcor Flexibles, roasters running three shifts on one machine could save on average 280 hours of downtime and up to 10% annual cost savings due to increased production efficiency (depending on machine model and the type of hard valve being replaced).

One customer, leading Danish coffee producer Copenhagen Roaster, jumped at the chance to eliminate hard valves. ��“The process of applying hard valves always created some difficulty in production, so Vento came at just the right time,” says Søren Sylvest, co-owner of Copenhagen Roaster. “The pilot ran smoothly and the performance of the system is impressive; it does the job perfectly. We also loved that it allowed us to move our venting system to the back of the pack.”

Vento can be integrated on any of Amcor’s typical triplex laminates for coffee soft packs, and customized to meet a customer’s specifications.

Amcor Flexibles, Hall 9, Booth B15

6. The Pharma-Multi-Act tamper-evident label for syringes is released, thanks to a perforation, when healthcare professionals flip up the cap, which they can do easily. The one-step cap opening/label release saves valuable time and provides an irreversible indication of initial opening.

Additionally, manufacturer Schreiner MediPharm explains that, when opening Pharma-Multi-Act, a readily accessible, detachable documentation label is exposed on the cap. This, too, can be easily peeled off, even when wearing gloves. This detachable label can be used for a variety of reasons: an initially covert warning message, an additional security feature for authentication, an integrated near-field communication (NFC) chip for interactive applications, or a temperature or ultraviolet (UV) indicator that is activated by opening the label.

Schreiner MediPharm, Hall 7A, Booth B02

7. Flexible packaging for foods can be enhanced with two new co-polyamides from leading chemical and plastics company BASF.

• The partially bio-based Ultramid Flex F38L co-polyamide for vacuum skin packaging is immediately soft (without conditioning) and extremely clear, with high melt stability for blown film leading to bubble stability and increased blow-up ratio (BUR). With a unique oxygen and carbon dioxide (CO2) transmission ratio compared to other polyamides, this film enhancer is especially suitable for modified atmosphere packs and cheese-ripening bags.

• Also significantly softer and clearer than other co-polyamides, the new Ultramid C37LC helps shrink films achieve higher hot water and hot air shrinkage. According to the company, reducing a product’s crystallization temperature and melting point significantly cuts the curling of asymmetric films with polyethylene (PE) or polypropylene (PP).

BASF, Hall 10, Booth 43

8. Pharmaceutical packaging specialist Rondo will be presenting its new Supply on Demand service, which ensures short delivery times—less than one week—for small quantities of secondary packaging items such as folding cartons, leaflets and labels.

The company is able to achieve such timely deliveries by:

• Using new printing technologies to shorten set up times, which also helps avoid a lot of the waste typically generated during printing;

• Establishing an automated workflow system internally and integrating with customers via an enterprise resource planning (ERP) program;

• Harmonizing quality processes with its customers to avoid redundant inspection activities—while still maintaining strict compliance with good manufacturing practices (GMP).

Rondo also offers the option of printing batch numbers and the expiry date directly on folding cartons so pharmaceutical companies don’t have to deal with the hassle of adding an inline printing system on their packaging lines. Eliminating this step on the packaging line could mean higher outputs.

Rondo, Hall 16, Booth A25

9. As part of its Consumer Protection zone, ink manufacturer Sun Chemical will show a new near infrared-based food contaminant detection system that identifies plastic fragments and other contaminants in food that used to be hard to detect. The system uses a near infrared (NIR) fluourescent dye and an NIR “reader” to ensure food is safe as it leaves the processing line.

Sun Chemical, Hall 7a, Booth C06

10. Toyo Ink Group addresses the safety of packaging materials and other components for food and beverage products with its new Elex-one series of electron beam (EB)-curable flexographic inks, which are 100% solid—an industry first, according to the company—and contain no volatile organic compounds (VOCs) or photo-initiators. This non-petroleum-based solvent keeps flexible food and beverage packaging free from unwanted residual compounds.

Toyo Ink will also present a seminar on new electron beam technologies for packaging, together with its development partners Uteco Group and Energy Sciences Inc., on both Fri., May 5, and Mon., May 8.

The company also focuses on sustainability. Toyo ADL’s LabelMelt series of hot-melt adhesives are made from plant-derived materials and are free of solvents, thus aiding a package’s recyclability. And using this product, according to the company, reduces CO2 emissions by 95% compared to conventional shrink-sleeve labels.

Toyo Ink Group, Hall 18, Booth D15

11. A new EPET class IV material can be extrusion blow molded into eye-catching clear containers with handles, on the HyBlow 407 D blow-molding machine from Bekum. The recyclable material melts completely in the extruder without causing excessive wear, according to the company. The blow molder also removes flash and integrates bottle transfers.

Bekum, Hall 5, Booth D37

12. Selig plans to unveil a new closure liner—called DeltaFuze—that protects fatty foods, despite the challenges of induction sealing through such products.

Selig, Hall 7 (level 1), Booth B06

****************************************************************************

Learn what it takes to innovate in the packaging space at PackEx Toronto 2017 (May 16-18; Toronto, Ontario, Canada). Register today!

About the Author(s)

You May Also Like