Corrugated Cardboard? No, it should be called: Embossed Cardboard

January 30, 2014

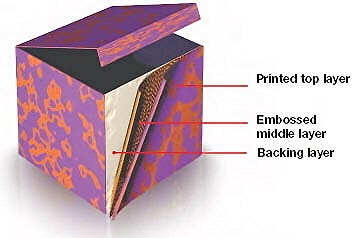

The closest Avenira’s new material comes to corrugated cardboard is that it is manufactured in several layers. It is produced in three or more layers and the middle layer, the one that is usually fluting in corrugated cardboard, consists of small bubbles in a stochastic pattern. That saying, the correct name should be: “embossed multilayer board”.

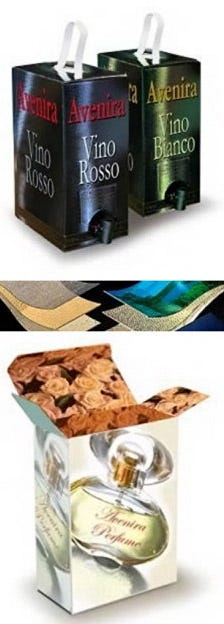

The material, developed by Finnish Avenira Oy, is a multilayer laminate delivered in sheets. With a weight area between 300 – 600 gr/m2, thickness from 500 – 1.400 microns, sheet size 720 x 1.020 cm, the material offers exceptionally high stiffness and compression in relation to its low basis weight. Its A-B-C sandwich structure provides an integrated moisture barrier. At the same time, for the composition of the sandwich customers have a wide choice of materials, from FBB (folding box board), SBB (solid bleached board), liners, films, fabrics to non-woven materials.

The advantages of the material can be defined in three words: stiffness, smoothness and barrier. Thanks to the production method the material’s stiffness is relatively even in all directions unlike corrugated cardboard where it differs depending on design. Compared to thick cardboard paper Avenira is stiffer, while the material gets barrier layers through one or two layers of glue.

The advantages of the material can be defined in three words: stiffness, smoothness and barrier. Thanks to the production method the material’s stiffness is relatively even in all directions unlike corrugated cardboard where it differs depending on design. Compared to thick cardboard paper Avenira is stiffer, while the material gets barrier layers through one or two layers of glue.

Being a three layer laminated board with mechanically embossed middle layer, the material enables high bulk and stiffness values for the sandwich construction. In spite of its lightness, Avenira is extremely rigid and offers excellent protection during transport and storage.

Because the material’s “fluting” consists of a layer of small bubbles, a very even surface is achieved that enhances printing. The attractive and colourful look due to the smooth surface enables the most refined printing. Avoided is the washboard phenomenon that easily arises when printing on corrugated cardboard, so that Avenira can go directly to offset without preprint. The creasing and folding tools are within carton rules.

The material is easily recyclable. The manufacturing, according to the company, is environmentally friendly as it requires only a small amount of energy, and eliminates the use of water or steam in its process.

These Poor Old Rheumatic Consumers - According to a report by The Center for Culinary Development (CCD), Baby Boomers, who account for a third of the US population and spend about USD 2 trillion each year, place a significantly higher monetary value on convenient packaging compared to other generations. A large part of the Baby Boomers is confronted with arthritis or hand injuries, which make it impossible for them to easily open screw caps, or for that matter packages in general.

These Poor Old Rheumatic Consumers - According to a report by The Center for Culinary Development (CCD), Baby Boomers, who account for a third of the US population and spend about USD 2 trillion each year, place a significantly higher monetary value on convenient packaging compared to other generations. A large part of the Baby Boomers is confronted with arthritis or hand injuries, which make it impossible for them to easily open screw caps, or for that matter packages in general.

Responding to this increasing international demand for convenient screw caps, Tetra Pak launched the Tetra Brik Edge, the packaging solution for chilled liquid dairy products, while its most important competitor SIG Combibloc introduced the new generation of the combiSmart screw cap …. continue reading

About the Author(s)

You May Also Like