Taking technology

to 'flextremes'

January 29, 2014

Could flexible packaging be experiencing a technical revolution? With many practical advances exemplified by winners of the 2002 Flexible Packaging Achievement Awards competition, it's clear that flexible packaging is becoming ever more sophisticated. The Flexible Packaging Association's annual competition served up high-performing and attractive packaging structures, replete with convenient and/or value-added components, as well as exciting visuals, thanks to further printing and converting developments.

Covering a broad range of applications in four categories--Packaging Excellence, Technical Innovation, Environmental Achievement, Printing Achievement--a total of 23 awards were shared by 18 of the 43 flexible packaging developments entered in this year's competition. From overcoming palletizing and shipping challenges to increasing shelf life and paving the way for products to enter entirely new venues, the winning flex-packs described here represent structural, visual, environmental and technological breakthroughs for products in three general-use classifications: retail, institutional, and industrial. In addition, FPA members voted on the Member's Choice Award, selected from all entries.

Two winning packs also earned the Highest Achievement Award, having contributed most to the advancement of the industry. The award went to Cryovac for Nestlé's® Buitoni® fresh pasta package (photo 1) and Cargo Technology (photo 2) for the AirLiner®.

|

|

Oxygen-scavenger lidding extends pasta shelf life

An invisible oxygen-scavenging technology that could have a major impact on modified atmosphere packaging is key to the Highest Achievement Award for Nestlé's Buitoni fresh refrigerated pasta package (picture above) (1). Used as a lidding material to seal semi-rigid trays of refrigerated pasta packed under modified atmosphere, the film from Cryovac Div., Sealed Air Corp., also won a gold award in technical innovation. Called OS Films lidding, the material removes residual oxygen from the package, achieving oxygen levels of less than 1/10 of one percent in three to eight days (also see PD, March '99, p. 88).

Nestlé, which as of presstime has an exclusive on the technology for pasta products, adopted the patented film in May '01, as a replacement for a conventional barrier film used as lidding for Buitoni pastas in 7-, 9- and 20-oz tray sizes. Nestlé's OS Films lidding reduces oxygen inside the trays to increase the shelf life of the Buitoni pasta products by 50 percent, confirms Nestlé's director of packaging development Jim Smith.

The reduced-oxygen levels are dependent upon having an initial oxygen concentration typically less than 2 percent inside the package, which means the product must be packaged under modified atmosphere conditions, points out Cryovac's Tom Kennedy.

"It's not, by itself, a substitute for gas flushing. It could allow a processor to start with a higher oxygen concentration than they normally might otherwise be able to use, but in most applications, it cannot drive the oxygen concentration down to those levels starting at atmospheric oxygen."

Cryovac has been developing OS Films lidding technology for a decade. The technology requires no moisture to activate, allowing the system to work effectively in both low- and high-humidity applications. Cryovac converts the film using existing coextrusion processing and converting capabilities. It describes the film lidding in Nestlé's case as a 3.5-mil lamination that's heat-sealed to a semi-rigid, thermoformed, multilayer film base tray with a scavenging-film-compatible polyethylene sealant. The oxygen scavenger is incorporated into the film as a proprietary polymer, coextruded into a discrete film layer and adhesively laminated to a polyester substrate, coated with a polyvinylidene chloride barrier layer.

Integral with the film and invisible to the naked eye, this built-in, "unseen" oxygen scavenger offers an alternative to oxygen-scavenging sachets, labels or coatings without altering the transparency of the film or the film-viewing window to Nestlé's pasta in the tray. Through a patented process, the scavenger is activated on-demand, by Cryovac's Series 4100 ultraviolet light-triggering system.

Nestlé installed the bank of light-triggering units on an existing horizontal thermoform/fill/seal packaging line at its Buitoni pasta packaging facility in Danville, VA. As the UV light from the 4100 system shines through the film and reaches the special polymer, the oxygen scavenger is activated just prior to filling and sealing.

While Nestlé is one of the first to adopt the OS1000 polymer-based oxygen-absorbent film for filled and cut versions of Buitoni refrigerated pastas, Kennedy says Cryovac is also working with several other customers to qualify films and ready them for the market.

"The Nestlé film structure is only one way the oxygen-scavenging OS Films technology can be delivered," he says. "It can also be produced in other formats, such as a fully coextruded film as well as a laminated format. We've developed a family of these films–it's not limited to one format. We've been working for several years to continually improve the oxygen-scavenging performance and its triggerability."

The Buitoni pasta tray lidding is trap-printed on the outer edge in black with opening and refrigeration instructions; a pressure-sensitive spot label printed in bright green with product specifics, the Buitoni logo and branding is placed on top of the lidding.

"The polymer is let down into a discrete layer in the film, and the scavenging reaction is triggered by passing the film through the UV-triggering unit, which initiates the oxygen-scavenging reaction."

Rollstock of the lidding is slit into tray-applicating widths and sent to Nestlé USA's plant in Danville, VA. There, the pasta is packaged on production lines equipped with a modified atmosphere horizontal thermoform/fill/sealing system and the Series 4100 UV-light-triggering unit.

The UV light system can be situated at the infeed or outfeed of a packaging line. As the top web of film unwinds into the tf/f/s machinery, it is diverted into the UV light-triggering unit, which activates the scavenger layer that starts the scavenging process. Then the film is brought back into the standard web path of the packaging line so that it can be sealed onto the bottom web. Subsequent oxygen removal and gas flushing evacuates most of the oxygen in the package; the scavenger handles the remaining oxygen.

Nestlé conducted extensive in-house quality, shelf life, shipping and performance testing for about a year to ensure that the lidding material would perform consistently throughout the Buitoni manufacturing process, Smith notes. "While the rest of Buitoni packaging remains the same, and the new lidding doesn't look any different to consumers, the 50-percent boost in shelf life versus the previous package is a real sales bonus," he says.

"One advantage we saw is the clarity the film," Smith tells PD. "It's important to see the product. Other films tended to be more gray or discolored. And it improves shelf life significantly. We're excited about the potential the lidding film offers. It performs very much like the material we used previously, but which had no oxygen-scavenging capabilities." Circle No. 608.

Getting freight delivery down cold...or hot

The Cargotech Airliner®, designed by Cargo Technology, San Diego, also won a Highest Achievement Award, for insulating technology used in shipping temperature-sensitive (cold, warm and frozen) products (2). The AirLiner inflatable liner transforms a shipping case into a cooler or heat-containment device. Available in 12 sizes, the container was launched last March.

The AirLiner prevents leaks, breakage and cracking of products shipped by expedited freight. Shipped and stored flat, which can lower storage, handling and shipping costs, the inflatable shipping case liner also keeps cold products cold, and warm products warm for extended periods. It basically restricts heat from penetrating the container wall–from the outside in or the inside out.

The AirLiner prevents leaks, breakage and cracking of products shipped by expedited freight. Shipped and stored flat, which can lower storage, handling and shipping costs, the inflatable shipping case liner also keeps cold products cold, and warm products warm for extended periods. It basically restricts heat from penetrating the container wall–from the outside in or the inside out.

Behind its patented internal heat-barrier technology are layers of reflective barrier film, heat-sealed into a special geometry to form panels that can be inflated and filled with compressed air or inert gas, such as Argon. The panels can also be easily deflated for compact, convenient disposal. The gas-filled panel technology was developed under a Department of Energy grant as a spinoff of the Lawrence Berkeley National Laboratory's Environmental Technologies Division's research on multipaned windows and other applications in the '80s.

David McKinney, vp of operations at Cargo, says his company produces the AirLiner in a proprietary process using a special bagmaking system the company designed with Convertec. The liner is made from a five- to seven-layer structure incorporating outer layers of a nylon coextrusion from Pliant Corp., and proprietary inner layers of polyolefin film as well as radiant barriers, heat-sealed into a geometric structure that forms a unique honeycomb-shaped baffle system.

When inflated, the honeycomb baffles block the three modes of heat transfer: radiation, convection, and conduction. There are two-baffle and four-baffle liners, in 1- and 11/2-in. thicknesses, respectively. "We can ship anywhere from 1,200 to 8,000 deflated bag liners on one pallet, so you can imagine the warehouse savings [versus alternative rigid cushioning devices]," McKinney says.

Also winning gold in the technical innovation category and gold in environmental achievement, the AirLiner is printable by conventional methods with product and brand information. Developed as an alternative to rigid foam packaging, the flexible insulating liner and shipper offer easy disposability.

Marketing director Diana Prat says while the AirLiner is currently used for all sorts of cold items, it's also fine for warm-temperature applications, such as shipping tropical fish and exotic flowers that must be kept at or below certain temperatures. One customer that became an AirLiner beta site and later a full-fledged customer is Save On Seafood, a fish processor in St. Petersburg, FL, which adopted the AirLiner to pack its cases of portion-packed seafood distributed to supermarkets and restaurants. Circle No. 609.

Shipping broccoli without ice

Another winning shipping-case liner developed to create the right modified atmosphere for fresh-cut produce, Apio's Ice Eliminating Intellipac (3) can also keep products fresh  without the need for ice inside a shipping case. But this liner features a proprietary, breathable membrane designed primarily for fresh-cut produce, especially broccoli. The Intellipac™ technology was developed by the Intellipac Div. of Apio, a Guadalupe, CA-based wholly owned subsidiary of Landec Corp. Specializing in modified atmosphere packaging for fresh produce through the Intellipac Div., Apio uses its technology to ship and export fresh produce to retailers, clubstores and foodservice marketers.

without the need for ice inside a shipping case. But this liner features a proprietary, breathable membrane designed primarily for fresh-cut produce, especially broccoli. The Intellipac™ technology was developed by the Intellipac Div. of Apio, a Guadalupe, CA-based wholly owned subsidiary of Landec Corp. Specializing in modified atmosphere packaging for fresh produce through the Intellipac Div., Apio uses its technology to ship and export fresh produce to retailers, clubstores and foodservice marketers.

The pressure-sensitive membrane modifies the atmosphere inside the hermetically sealed case liner by adjusting the ratio of oxygen and carbon dioxide to specifically match the requirements of the fresh-cut produce it contains. The membrane is selectively permeable to oxygen and CO2, so as the produce consumes oxygen and gives off CO2, the membrane allows the CO2 to escape the liner at a higher rate than the oxygen. This helps maintain quality and compensates for temperature abuse by maintaining an optimal atmosphere inside the case liner as temperatures change during distribution, as well as allows the fresh produce to be shipped to distant markets without the need for ice and moisture-resistant corrugated shippers.

Says Apio's director of marketing Jennifer Browder, "We use the Intellipac liner with many high-respiring vegetables, including broccoli and green onions."

Apio, which launched the case liner in November '00, packs its cases with a 2-mil PE liner and loads the bulk produce before hermetically sealing the case either automatically or manually, Browder says. Affixed over a hole punched into the bag liner, the Intellipac membrane comprises a permeable substrate, coated on one-side with what Intellipac defines as a proprietary side-chain crystallizable polymer that selectively transmits oxygen and CO2, according to the particular beneficial atmosphere requirements for the produce inside the package, Browder tells PD.

At a certain temperature, the properties of the polymer change, becoming more permeable, explains Intellipac's Sue Free. "The higher the temperature, the more quickly produce respires and the more permeable the membrane becomes."

The only transmission of gases is through the Intellipac membrane. "It creates a modified atmosphere within the sealed liner specifically tailored to the requirements of the produce inside the liner. Thus, we can ship produce without ice," Browder says.

Winning both a gold in packaging excellence and a silver award in environmental achievement, the Intellipac liner can extend the shelf life of broccoli to at least 17 days. With a CO2/oxygen-permeability ratio of 5:1, the broccoli membrane is also designed to reduce dehydration and discoloration of the produce. Circle No. 610.

NesQuik label is no shrinking violet

Nestlé USA Beverage Div.'s NesQuik™ flavored milk drinks in a handsomely sleeve-labeled, contoured polyethylene terephthalate bottle (4) have rung up impressive sales since debuting on the market in April '99. Posting a notable 220-percent increase in those launch markets for extended-shelf-life product sales since the early part of '99, the distinctive package is also a winner with the FPA judges, capturing one of three gold awards presented for packaging excellence.

debuting on the market in April '99. Posting a notable 220-percent increase in those launch markets for extended-shelf-life product sales since the early part of '99, the distinctive package is also a winner with the FPA judges, capturing one of three gold awards presented for packaging excellence.

Nestlé engaged Alcoa Flexible Packaging to help transform Nestlé's Quick in a waxboard gabletop carton into NesQuik, which is wowing the market with its hourglass-shaped, clear PET bottle, dramatically sleeved in Alcoa's glossy full-body heat-shrinkable label, enhanced with colorful high-fidelity graphics.

Together with an upbeat, upscale bottle, aseptically packaged on systems that contribute to the milk drink's considerable 90-day extended shelf life, the dynamic sleeve labels are giving Glendale, CA-based Nestlé Beverage a cutting-edge package for NesQuik with the brand equity of Nestlé's Quick. The long shelf life allows Nestlé Beverage to expand the product's marketing potential to additional consumer groups that might not have otherwise tried NesQuik.

Notes Alcoa Flexible Packaging's Victoria Welch, "One bottle and roll labels for the different stockkeeping units make the product's increased choice of flavors [banana; strawberry; chocolate; and fat-free chocolate] easy to assume for the dairies that bottle the products." The bottle is the same for each flavor, but the labels, which come in a more easy-to-inventory rollform, can be printed to match each of the four milk flavors, and can be placed on the bottles as required, eliminating what could have otherwise been substantial inventories of preprinted gabletops.

Alcoa Flexible Packaging converts, prints and seams the full-body shrink-sleeve labels at its facility in Downingtown, PA, using Eastman's Embrace 50-micron (2-mil), cast-extruded monolayer polyethylene terephthalate glycol (PETG) copolyester provided by Vonset. The film was chosen for its smooth shrink, machinability and environmental compatibility with the PET bottle. Alcoa Flexible Packaging's Downingtown facility reverse-prints the sleeve material by gravure with the NesQuik graphics and a yellow color scheme.

Alcoa converts the sleeves as 113-mm-wide rollstock to meet the production needs of the many dairies across the U.S. that bottle the products for Nestlé. The sleeve labels snugly fit the contours of the bottle comfortably, affording an ergonomic fit in the hand.

"We had to do a bit of work on predistorting the sleeve artwork so that when the sleeve shrinks down on the bottle, the graphics look right," notes Alcoa's commercial shrink sleeve manager Terry Copenhaver. "Only a shrink label would work for this kind of bottle. A wraparound shrink label might not have had enough percentage of shrink to work properly."

Alcoa Closures Systems also supplies the bright blue, wide-mouth, wide-ribbed injection-molded polypropylene screw cap featuring the NesQuik bunny embossed on top.

Nestlé USA Beverage Div.'s spokesperson Terri Haywood sums up: "The package has been tremendously successful in terms of enabling us to penetrate multiple distribution channels, primarily convenience stores where we've really seen huge growth in this particular product. From a consumer standpoint, it's functional, portable and fits in the car cup holder, and the sleeve label has been really effective because it's extremely colorful and really stands out from some of the other products out on the shelf. And with the transparent cutout on the sleeve, consumers can see the product, which is very appealing and important, and the NesQuik bunny is also an eye-catcher."

The16- and 32-oz bottles of low-acid product are filled by several dairy copackers, including WestFarm Foods in Portland (see PD, Dec. '00, p. 54). WestFarm equipped a bottling line for NesQuik with Serac's sterile, fill-by-weight system. The line can run 300 of the PET pt- or qt-size bottles/min. That facility used machines from PDC Intl. to apply the sleeve labels. Circle No. 611.

Sleeve sparks Fuze

When it comes to beverage sleeve labels, Alcoa Flexible has the midas touch, as it won another gold award, this time for printing achievement for a set of spiritedly decorated full-body shrink labels for new Fuze™ health beverages (5). Covered in PD last month (see Feb. '02, p. 10), the packaging's intense color and rich, explosive graphics created by Fuze designer Paula Patricola convey plenty of vitality for the five refreshing drinks from Fuze Beverages, Englewood, NJ.

The beverages, marrying herbs, minerals and vitamins presented in an 18-oz custom glass bottle from Owens-Illinois and Vitro, were initially marketed in Northern California and New England. To prevent scuffing and enhance the label's glossy appearance without special overcoats, Alcoa Flexible converts the bottle's 2-mil polyvinyl chloride sleeve-label rollstock and reverse-prints it by gravure in seven colors, including a double bump of white for a high degree of print opacity. Color schemes of bright yellow, sky blue or cherry red are coded to correspond with the unusual fruit, vitamin and mineral combinations of flavors exotically named Focus, Replenish, Slenderizer, Stamina and Vitaboost.

in an 18-oz custom glass bottle from Owens-Illinois and Vitro, were initially marketed in Northern California and New England. To prevent scuffing and enhance the label's glossy appearance without special overcoats, Alcoa Flexible converts the bottle's 2-mil polyvinyl chloride sleeve-label rollstock and reverse-prints it by gravure in seven colors, including a double bump of white for a high degree of print opacity. Color schemes of bright yellow, sky blue or cherry red are coded to correspond with the unusual fruit, vitamin and mineral combinations of flavors exotically named Focus, Replenish, Slenderizer, Stamina and Vitaboost.

Alcoa also prints these labels at its plant in Downington, PA, using film from Vonset America and uses similar predistortion techniques for these rolls of sleeve labels, just as for the aforementioned NesQuik application. The converter says the four-color process printing allows it to achieve a challenging vertical gradation down to the length of each shrink sleeve label, while keeping the realism of the fruit and plants featured on each design. Graphics illustrate such things as grapes for a grape-Aronia drink combination, Agave cactus leaves for an Agave cactus-containing flavor, and oranges, carrots and others. In order to ensure the correct proportions once the sleeves are shrunk onto the bottles, Alcoa carefully predistorts the artwork during sleeve prepress production.

Alcoa Flexible produces the full-body sleeve labels replete with the neon color schemes for the tapered milk-bottle-style container, which is topped with a 38-mm steel lug-style closure, litho-printed and produced by Silgan. The bottles are filled by copackers American Can, Beverage Capital and Pokka USA.

Fuze Beverages partner Lance Collins says this spring, the preservative-free, noncarbonated drinks will head into additional markets. Five additional stockkeeping units will be available soon. "We love the labels. The most important thing is the impulse buy, so we wanted to catch the consumer's eye and imagination." Circle No. 612.

Film/foil packet with pep

Technical innovation is also apparent in a condiment-sized packet for one of the most widely recognized pepper sauces, McIlhenny's Tabasco® (6) green pepper sauce. Winning a gold award in technical innovation for Rollprint Packaging Products, the packet structure may be one of the first applications featuring a polyester-based extrusion coating on a film.

Rollprint says the structure combines reverse printing, adhesive lamination, extrusion lamination and coextrusion coating processing techniques to create an  entirely new flexible material for McIlhenny's green pepper sauce. The portion-controlled packet prevents emission of off flavors in the green sauce, and scalping or leaching, as well as the delamination that would occur with other films.

entirely new flexible material for McIlhenny's green pepper sauce. The portion-controlled packet prevents emission of off flavors in the green sauce, and scalping or leaching, as well as the delamination that would occur with other films.

The easy-tear packet for McIlhenny Co., Avery Island, LA, measures 11/8 x 21/2 in. It's made by Rollprint's Addison, IL, facility using a multilayer polyester/coextrusion-coated polyester blend sealant/aluminum foil/polyester, reverse-printed flexographically in three colors on the outermost polyester layer.

The coex-coated polyester sealant technology is revolutionary in that it's not only convenient and cost-effective, but it's also what Rollprint defines as "chemically clean and inert," yet can perform at high processing speeds. The packet's foil layer acts as a barrier, while an opaque white film layer provides a suitable background for printing and a proprietary, polyester-based, chemical-resistant sealing layer that is coextrusion-coated. The chemical-resistant sealant layer protects the foil and affords a durable, hermetic heat seal.

Product-compatibility issues associated with the aggressive, spicy, pepper composition of the sauce could potentially have their way with packaging films. The powerful flavor ingredients have been known to leach through some film structures and delaminate them after filling. Chemical-resistant adhesives and primers also help assure packaging integrity, according to Rollprint's product development manager Karen Berger.

Bonding is important between the packet layers, emphasizes Berger. "The multilayer structure is put together in such a way as to ensure a proper bond between all of the layers and to work well with the pepper sauce."

Despite its small size, the new heat-sealable composite packet maintains a giant presence with its clear-cut, easily recognized brand identity and legible product information printed on both front and back packet panels. Graphic elements on the front panel of the packet include an illustration of the bottle of sauce and the well-known McIlhenny's Tabasco logo on a white background. The back panel presents product copy and the logo on a green background. Berger says additional packet graphics and structures are in the works for some of McIlhenny's other sauces. Circle No. 613.

TE slider pouch for carrots

Eldorado Farms' redesigned package for Eldorado Farms Market Prize peeled carrots (7) confirms that through value-added features, flexible packaging continues to advance sales and the convenience of fresh-cut produce. Converted by Pliant, the bag won a gold award in packaging excellence. Eldorado Farms' new user-friendly carrots pack is topped with Pliant's convenient Relliant™ Series 200 slider zipper closure over an inner-gusseted liner that's perforated for opening on first use. The new package hopped into supermarkets in Western Canada provinces in September '01.

Revising its conventionally sealed PE pillow-pack bag that  wasn't reclosable with the gusset-topped structure and slider zipper that's not only easy to open but is also tamper-evident, the Redcliff, Alberta, grower has good things to say about its new carrots package. Pliant's Relliant closure has a large green clip tab molded with an arrow on top that points in the direction of opening to remove any doubt as to how to use it.

wasn't reclosable with the gusset-topped structure and slider zipper that's not only easy to open but is also tamper-evident, the Redcliff, Alberta, grower has good things to say about its new carrots package. Pliant's Relliant closure has a large green clip tab molded with an arrow on top that points in the direction of opening to remove any doubt as to how to use it.

More convenient for consumers, the dazzling new 2-lb bag for the Market Prize brand of peeled carrots seems to be leaving competitors foraging. Made by Pliant from 100-percent-recycled PE, the bag is punched with macroscopic holes to extend the shelf life of the carrots by allowing them to respire once packed. A wide bag opening affords unhampered access to the product.

Combined with a gusseted inner liner, the bag offers tamper-evidence, a secure seal and easy-open friendliness, all driving forces behind the redesign.Using its vertical integration capabilities, Pliant had its in-house art department in its Macedon, NY, production facility help create the custom package structure. Pliant produces the 2-mil monolayer blown low-density PE/ethylene vinyl acetate-blend film at another plant in Langley, BC, where the bagstock is surface-printed in six colors on an eight-color Paper Converting Machine Co. flexo press.

In addition, the upgraded bag gave way to a new look for the peeled carrots. Eldorado Farms wanted real packaging punch for the Market Prize brand, so decided to replace the conventional PE film pillow pack with Pliant's slider-zippered, blown linear LDPE-blend bag that displays impactful flexo-printed graphics in green, yellow and white.

Product copy appears on front and back panels in English and French. Together with eye-catching illustrations, product benefits details and vertical orange scrim lines (stripes running along the front panel to enhance carrot color and appearance), the bag aims to meet consumer needs throughout. A generous portion of bag film is left unprinted, so consumers can see the actual carrots through the film without interference.

Finished rolls of the bag material measure 29? in. W. The rolls are then shipped to Pliant's converting facility in Shelbyville, IN, where they're made into bags on Amplas MS 1400S side-welding equipment. The Amplas machinery forms the inner-gusseted liner and perforates the opening and is also equipped to apply the slider zipper in-line.

Worth its weight in carrots and more, the package upgrade was a real team effort, says Pliant sales representative Heber McDonald, who worked closely with Eldorado Farms on the project. "We're quite proud of the project. The Relliant closure is something we newly launched into the custom bag market. We all worked together on it. The project started with a pencil sketch. But it was no small feat. It was completed in a mere eight weeks, from concept to finish." Circle No. 614.

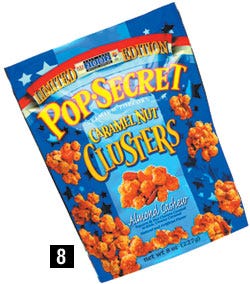

Olympic twist for Pop-Secret

A gold award winner in printing achievement went to a sparkling, flexo-printed, metallized polyester standup pouch that elevates the shelf presence of caramel nut clusters from General Mills' Pop-Secret (8). The crisp, shiny metallic film structure and dazzling graphics (designed in-house) eliminate all but the tiniest wrinkle in the pouch material, thanks to Printpack's use of an  extrusion lamination of polyester/reverse printing/PE/ metallized polyester/PE /film. The structure, which holds 8 oz of Almond Cashew Caramel Nut Clusters Premium Popcorn, maximizes visual appeal with a vivid blue-on-blue color scheme and bold popcorn and nut clusters floating on a stars-and-stripes background.

extrusion lamination of polyester/reverse printing/PE/ metallized polyester/PE /film. The structure, which holds 8 oz of Almond Cashew Caramel Nut Clusters Premium Popcorn, maximizes visual appeal with a vivid blue-on-blue color scheme and bold popcorn and nut clusters floating on a stars-and-stripes background.

Printpack says it converts and flexo-prints the crisp pouch film, which has enhanced stiffness, in eight colors on proprietary equipment at its facility in St. Louis. The results achieve a great tonal range from light to dark colors and enhance a shadow effect that appears on a red-and-white-striped banner illustrated at the top of the front panel.

According to Printpack, such shadowing techniques are tricky to achieve with most print processes. This one creates definition and contrast for the banner. ITW Minigrip provides the handy resealable zipper closure.

Shelf life of the package is about nine months. Also critical to converting the pouch is that no unique inks or coatings were required. The nut clusters, however, need maximum barrier protection, General Mills' PR spokesperson Kelley Walhof tells PD. "The nut clusters need a moisture barrier, so we use the metallized barrier pouch film. And the product also needs good oxygen barriers to aid stability of the nuts. The reseal feature maintains barriers after opening."

The product is contract-packaged on hf/f/s equipment by Roskam Baking Co. in Grand Rapids, MI.

Launched in January for the Olympic Winter Games, the pouch is printed with limited-edition, Salt Lake Official Supplier Olympics graphics as well as a General Mills cents-off coupon on the bottom gusset. Walhof says the promotional pack is available nationally for a limited time. However, if the product is successful, distribution could continue after the games. "The pouch is perfect for this tie-in with the Olympics," Walhof sums up. "It's convenient, and really sets this new product apart from the rest on store shelves." Circle No. 615.

Tyson's chicken pouch has snap, sizzle & pop

A gusseted, reclosable pouch for Tyson's Chik-Rib™, a frozen, microwavable, fully cooked barbecue-sauced product (9) available in clubstores, flies to a new level in converting expertise, outstanding imagery and increased freezer case impact. The pouch, which garnered a gold award for printing achievement for American Packaging Corp., holds a generous 48 oz (3 lb) of boneless, skinless, shaped chicken leg meat.

Not only is the adhesive-laminated pouch attractive, with its glossy, shiny feel and sophisticated, reverse-gravure-printed graphics that include luxurious metallic gold ink accents and mouth-watering product photography, it's also conveniently reclosable, thanks to a Presto Products' zipper closure located across the top. And to top it off, the pack is highly protective of the frozen chicken pieces inside.

Not only is the adhesive-laminated pouch attractive, with its glossy, shiny feel and sophisticated, reverse-gravure-printed graphics that include luxurious metallic gold ink accents and mouth-watering product photography, it's also conveniently reclosable, thanks to a Presto Products' zipper closure located across the top. And to top it off, the pack is highly protective of the frozen chicken pieces inside.

One of several clubstore packages Springdale, AR-based Tyson has recently developed, the Chik-Rib pouch affords substantial product protection from freezer burn and moisture and also guards against punctures of any sharp, frozen chicken pieces. The filled pack must retain integrity at temperatures to -5 deg F, and, in order to sustain rough handling in clubstores, must endure a 6-ft vertical drop without breaking or splitting.

"The frozen clubstore environment can often be rough on packaging, so we wanted the package to be sturdy enough to resist tearing and be reverse-printed to protect the fine print details," explains Tyson's creative services director Tom Cluck.

At its facility in Columbus, WI, American Packaging Corp. prints and laminates the pouchstock in-line before sending it to its plant in Story City, IA, for converting into wicketed pouches on Hudson-Sharp's PDI machinery. Semi-automatic bottom filling is performed by Tyson. Pouch material consists of a sturdy 48-ga clear PET, reverse-printed in eight colors, including specially formulated silver and gold inks, on a 10-color Cerutti gravure press, and adhesive-laminated in-line to a 3-mil, opaque white linear-low PE sealant film coex that enhances print opacity. The Packaging Group represented American Packaging to help coordinate the Tyson project.

"This is a new type of product, basically a darkmeat chicken, layered and cut like ribs," Cluck tells PD. "Market reaction to the product has been good. We designed the package graphics to really catch consumer attention."

He goes on to say that Tyson first thought about using a metallized bag. "But then we discovered that there were some really good metallic inks out there, so we created the bag graphics with a metallic gold border and outline of the Chik-Rib name on the front panel," he says. "Some gold ink can look green or brown but these are the just right color we were looking for. With rotogravure printing, it's hard to go wrong. The print quality in the photo vignette is extremely well done."

Tyson developed the packaging graphics in-house, Cluck says, all the way up to the prepress stage, through its own in-house creative package design and research department. "For this type of project, everything we do is a digital workflow, so the image on the package's front panel was shot digitally." Circle No. 616.

Perforated pouch scores big for Sargento

Described by Curwood, Inc. as the first-ever commercially sold slider/hermetic/gas-flushed package for shredded cheese, Sargento's shredded cheese packaging with the IntegraScore® opening feature was recognized with a silver award for packaging excellence (10) and also received the FPA Member'sChoice Award. Unveiled in November '00 (see PD, Dec. '00, p. 4), the flexible film pouch with a perforated "hood" and zipper slider closure is now used for 45 of Sargento Foods, Inc.'s cheese products, including its 8-, 12- and  16-oz retail shredded and 8- and 16-oz snack cube lines.

16-oz retail shredded and 8- and 16-oz snack cube lines.

The package, under development for approximately 18 months by Plymouth, WI-based Sargento and Pactiv Corp., trades its previous press-to-close zipper technology for one that uses Pactiv's Hefty® Slide-Rite® advanced closure system. Recalls Judy Fischer, senior packaging engineer for Sargento, of the package design process, "We knew we wanted to put the slider on the package, but it became quite a challenge because at that point, the sliders were only being used on food storage bags, where the slider feature was on the top of the package. Because of what we were packaging, we needed to have a hermetic package, so we had to enclose the slider system."

Enter film converter Curwood with its IntegraScore technology. IntegraScore allows the zipper slider to be completely enclosed by a film hood that is easily removed when the consumer detaches it from the pouch along a precise score. "That was one of the things we felt was critical for tamper-evidence," says Fischer. "To be hermetic, the package has to have more than just a closed zipper; it has to be completely airtight. That's what the IntegraScore did for us."

The film, a 60-ga biaxially oriented nylon/PE/1.75-mil modified ethylene vinyl alcohol and LLDPE, is supplied to Sargento in rollform. While Curwood media manager Melissa Schumacher declined to describe the process by which the IntegraScore is added to the film, she did indicate that it is produced before delivery of the material to Sargento.

According to news reported in the December '00 article, the Slide-Rite zipper is applied in-line at Sargento's operations using a retrofit closure application system from Pactiv. Mounted between the unwind stand and folder on a hf/f/s unit, the retrofit unit applies the slider zipper in three steps: The slider track is unwound from a master roll on the equipment; sliders and termination stops are applied to the patented zipper track on both ends; and the assembled track is applied to the pouch film after it is unwound and before it reaches the folding device.

Since its introduction, the tamper-evident, hermetic package has received an "absolutely fantastic" response, says Fischer. "Retailers think it's fabulous," she says. "We've even had to add more items in some stores because of the huge response from customers." Circle No. 617.

"Community" coffee carafe simplifies disposability

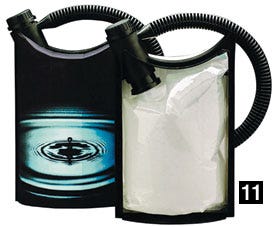

A 10-cup disposable beverage carafe for foodservice and retail use (11) is the latest invention from packaging solutions provider International Dispensing Co. of Millersville, MD. Designed to answer the call for a safer way to transport large amounts of coffee, while retaining product quality, the carafe incorporates three components, the central one of which is a sturdy, burst-resistant film pouch.

Speculates IDC president Gary Allanson,  FPA honored the flexible-pouch-based carafe with a silver award for packaging excellence because the container "opens up the possibilities of what can be achieved with flexible packaging."

FPA honored the flexible-pouch-based carafe with a silver award for packaging excellence because the container "opens up the possibilities of what can be achieved with flexible packaging."

A black plastic frame, incorporating a proprietary pour spout and an ergonomically designed handle for easy pouring and carrying, supports the carafe. The frame is injection-molded by Nutech from 20-percent regrind composed of a homopolymer PP. A continuous-thread closure with a mechanical breakaway from TricorBraun tops the spout. Attached to the frame at the spout is the 96-fl-oz, clear film pouch, custom-designed by Kapak to be both tear- and puncture-resistant. The filmstock is a 48-ga metallized PET/4-mil LLDPE laminate, using a proprietary adhesive system.

According to Allanson, key to the success of the application is the pouch film11's thermal properties. With existing bag-in-box coffee carrier technologies, he says, the aluminum bag film can "perspire," making the outer container soggy and soft. The IDC carafe, in contrast, sustains temperatures from zero to 250 deg F without film degradation or condensation for up to three hours.

Another requirement addressed during the film formulation process was the pouch's ability to be quickly and easily filled. Says Allanson, unlike Mylar bags that can be a struggle to separate for product dispensing, the IDC pouch opens easily, without pinch points that can cause product to back up and overflow.

The last component of the carafe affords users a customized branding solution. Attaching to the frame are two 10-in. side panels constructed of E-flute corrugated that can be flexo-printed by York Container with virtually any type of text or graphics, and sealed with a clear-coat finish for an upscale appearance. An extended-consumption version of the carafe features foam insulation cold-glued to the side panels.

Other advantages of the carafe cited by Allanson include its bottom-heavy design when filled, which provides stability during transport; the even flow of beverage dispensing made possible by the custom-designed spout; and the package's ability to drive incremental sales within the retail environment.The carafe is being used commercially by grocery retailers, coffee shops, caterers and others, and has received much interest from major grocery retailers and foodservice providers, Allanson relates. Circle No. 618.

Zipping up Kraft's cheese packaging benefits

Tearing away from conventional cheese packaging, Pechiney Plastic Packaging is providing Kraft with an 8-oz pouch using the Pacmac Slider Zip system for its shredded cheese products (12). The pouch, honored with a silver award for packaging excellence, departs from a traditional package with a header strip or tear tape and a press-to-close zipper. Instead, it uses the Zip-Pak Slider™ clip system from Minigrip/ZipPak, enclosed in a  shrouded header for tamper-evidence. A laser score–accessed by a tear notch at the package top–allows users tear off the hood and reveal the slider.

shrouded header for tamper-evidence. A laser score–accessed by a tear notch at the package top–allows users tear off the hood and reveal the slider.

"The depth of the laser score into the film was optimized for flawless opening without risk of premature stress cracking on the line of weakness," says Pechiney. "The film also is designed to allow efficient scoring as well as controlled tensile failure that provides the consistent package opening."A punch-out around the red slider allows the consumer easy access to the slider, but prevents it from moving freely back and forth. Once the header has been removed and the zipper opened, a peel seal in the zipper flange, which provides a hermetic seal, is revealed.

The pouch, a PET laminate, is filled on a Pacmac vf/f/s machine, which applies the slider clip system to the prescored film supplied by Pechiney. Regarding the insertion of the punch-out, Jan Boyd, dairy marketing manager for Pechiney, would only say that it is added after it leaves Pechiney's hands.

According to information submitted to the FPA by Pechiney's director of communications, Mark Lindley, the advantages of the new packaging system are three-fold: It is easier to open, easier to reseal, and provides greater security due to its tamper-evident features.

"Consumers of cheese–particularly shredded cheeses–have come to depend upon packages that are easy to open and can be resealed to ensure longer-term freshness," Lindley noted. "This new package is an improvement over existing packaging, primarily due to the easier-to-close zipper." Circle No. 619.

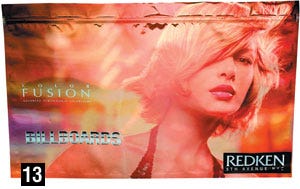

Reclosable mailer highlights Redken haircolor

For a market defined by image, a flexible film "envelope" containing promotional billboards for Redken's Color Fusion haircolor line (13) distributed to beauty salons last September was the epitome of chic. A 20 x 13-in. gravure-printed pouch with a zipper closure, the mailer gives new style to marketing materials typically enclosed in plain paper or plastic wrap.

Says Jane Dirr, president of Specialty Films & Associates, Inc., which received a silver award in packaging excellence for its converting of the project, "This package presents an entirely new way to view mailers and the part they play in sending a message about a company's philosophy and presence. The package allows the mailer to be the marketing tool."

Says Jane Dirr, president of Specialty Films & Associates, Inc., which received a silver award in packaging excellence for its converting of the project, "This package presents an entirely new way to view mailers and the part they play in sending a message about a company's philosophy and presence. The package allows the mailer to be the marketing tool."

Graphics, designed by Redken's in-house creative group, provide a surrealistic feel. Gravure-printed on a metallic polyester laminate, they present a head-and-shoulder view of a young model, awash in shimmering shades of burnt orange and gold. Sparse but striking silver-metallic type displays the product name, while the Redken logo is prominently depicted in the mailer's lower right-hand corner. Enclosed are four "billboards" to be used throughout the salon to promote the Color Fusion line.

Through the inclusion of a press-to-close zipper from Minigrip across the pouch top, the mailer becomes reclosable and, in effect, reusable. "The idea was that when the pouch was opened by the salon, it would stay intact and could be used for storage," explains Dirr, "Whereas, if the pouch was heat-sealed, it would have to be cut open, and if a tear-notch were used, the pouch could become torn during opening."

The film construction–a 48-ga metallized PET laminated to a 3.5-mil LDPE–was chosen because of its ability to achieve the aesthetics desired for the application. In addition, its ease of handling characteristics were a factor, as the 28,000 mailers were filled manually at Redken's Hebron, KY, distribution center.

The job, which uses four process and three line colors plus an overprint varnish supplied by Sun Chemical, was printed on 10-color Schiavi gravure press and laminated on a Comexi solventless laminator. Says Dirr, the mystical nature of the pouch's images made the job especially challenging, "as it was very difficult to identify on-press if there were any print issues."

While clearly a more expensive alternative to the standard paper or clear film envelopes usually used, the zippered pouch, notes Buddy Schnapp, Redken's senior director of purchasing, is worth its weight in gold. "Our customers are always looking for more image-type pieces," he says. "This mailer created more of a 'buzz'; there was much more excitement expressed by the salons when they received it." Circle No. 620.

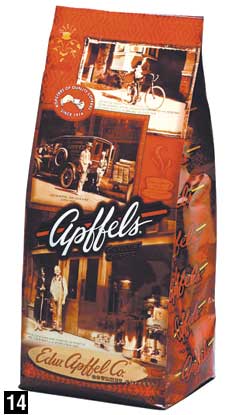

Coffee bag builds on tradition

Brewing up a rich blend of nostalgia and sophistication, RJR Packaging took home a silver award in printing achievement for the Apffels' Heritage Coffee Bag (14). The gravure-printed, standup bag was introduced in March 2001 to accommodate 5-lb quantities of more than 50 varieties of whole bean coffee from Edw. Apffel Co., which sells its products nationally in fine dining establishments, coffee houses and specialty coffee stores.

Comprised of graphics  culled from "a huge box of photographs, and old advertisements and logos," according to Michele Domadia, manager, design support for RJR, art for the bag was created to communicate the family-owned coffee-maker's long history in the Los Angeles area. "The objective was to convey the heritage they had within the community," she says. "They also wanted it to say 'coffee' immediately and to have a warmth and richness that says 'flavor.'" Artwork includes 11 sepia-toned photos framed with vintage borders combined with retro coffee-cup images and lattice-like background patterns. Gold-metallic text on the back of the bag tells the story of the company's growth since 1914.

culled from "a huge box of photographs, and old advertisements and logos," according to Michele Domadia, manager, design support for RJR, art for the bag was created to communicate the family-owned coffee-maker's long history in the Los Angeles area. "The objective was to convey the heritage they had within the community," she says. "They also wanted it to say 'coffee' immediately and to have a warmth and richness that says 'flavor.'" Artwork includes 11 sepia-toned photos framed with vintage borders combined with retro coffee-cup images and lattice-like background patterns. Gold-metallic text on the back of the bag tells the story of the company's growth since 1914.

When it comes to gravure printing technology, bag graphics, which were created over a period of nearly six months by RJR's design team, "push the envelope," says Domadia. "Just the sheer amount of detail was a challenge," she says. Multidirectional vignettes, duotones, and special effects used to make the bag's metallic-gold ink appear transparent all add to the complexity of the nine-color job, which is printed on a 10-color Rotomec press.

Regarding the vignettes, Domadia says: "We have to work very hard to produce the vignettes in order to create a very nice, smooth transition from basically 100 percent of an ink, fading off to nothing. That's pretty difficult to do with gravure, especially with the size presses we use." A translucent effect, used with the Apffels' gold-metallic logo featured on the bag's lower front, is achieved by using "a bit of a screen value of the gold, overprinted with a very light screen value of another ink," she explains.

Described by RJR only as a reverse-printed polyester foil sealant film laminate, the specific bagstock for the application was chosen due to its compatibility with Apffels' filling equipment, as well as its performance characteristics. "One of the things we typically look for is the film's creasing and memory," says Domadia, "so that by the time you fill the bag, it's not saggy-looking, it's still crisp." Inks are a modified nitrocellulose formulation, mixed in-house using bases from a number of suppliers.

RJR supplies both rollstock and premade bags to Apffels, which applies preprinted labels on the bag front to designate coffee variety. Once filled, bags are fusion-sealed.

According to RJR, the result of the collaboration has been very positive. Caron Apffel-McIntosh, in charge of graphic marketing at Apffels, for whom this project was "a labor of love," affirms, "We are thrilled with the outcome of this project. It's been very well-received by our customers and has become a real conversation piece."

New film provides longer cheese shelf life

Pechiney Plastic Packaging's Generation Flex film, winner of a silver award for technical innovation (15), provides a new option for natural cheese packaging. The film, which is produced by a tandem extrusion lamination process, consists of PET/coex EVOH/OPP/extruded EVA sealant layer. It is available in low-profile, high-profile and high-profile metallized versions that range from 3- to 3.6-mils thick, depending on the product application.

The implementation of this proprietary EVOH coextrusion technology allows an EVOH barrier to be incorporated into the cheese film during lamination. This eliminates processing concerns typically associated with the extrusion of heat-sensitive materials, such as EVOH, including such issues as gels, appearance and excessive downtime for process maintenance.

The implementation of this proprietary EVOH coextrusion technology allows an EVOH barrier to be incorporated into the cheese film during lamination. This eliminates processing concerns typically associated with the extrusion of heat-sensitive materials, such as EVOH, including such issues as gels, appearance and excessive downtime for process maintenance.

This coextrusion process produces a final structure that significantly increases shelf life during typical cheese storage conditions. Tests under standard conditions demonstrated more than twice the shelf life of the PVDC-coated film. EVOH also produces a final structure using materials that are all fully recyclable. Generation Flex, which is being used by a number of cheese manufacturers across the country including Land O' Lakes, can be run on existing packaging equipment without any changes. Circle No. 622.

Pizza film costs less, looks better

A new pizza film from Pechiney Plastic Packaging (16) that features patented nylon coextrusion technology with peelable sealant technology, won a silver award in technical  innovation. Introduced in mid-2001, the film, which is produced at Pechiney's plant in Des Moines, provides improved overall package integrity at a significant cost savings for Schwanns Sales Enterprises, Marshall, MN, producer of Freschetta pizza, as well as for other producers of rising-crust pizzas. The unique nature of the coextruded top web provides a tighter vacuum pack around the pizza toppings, resulting in increased visual appeal to the consumer.

innovation. Introduced in mid-2001, the film, which is produced at Pechiney's plant in Des Moines, provides improved overall package integrity at a significant cost savings for Schwanns Sales Enterprises, Marshall, MN, producer of Freschetta pizza, as well as for other producers of rising-crust pizzas. The unique nature of the coextruded top web provides a tighter vacuum pack around the pizza toppings, resulting in increased visual appeal to the consumer.

Improved package integrity reduces the number of "loose" packages, which result in frosting of the clear non-forming web, obstructing the consumer's view of the product. Peelable technology provides a uniform peelable seal that allows consumers easy access to the package without need for knives or scissors. Whitening of the seal after opening offers the consumer a tamper-evident seal. The package also offers improved efficiencies during packaging, improved package integrity, reduced channel leakers, and reduced contamination leakers, leading to less downtime and less product rework.PD has learned that Freschetta pizza is being run with the new film on Multivac hf/f/s equipment at the Schwanns plant in Florence, KY. From an operating standpoint, only minor machine adjustments are required to run the new film optimally at existing or greater line speeds. And the unique film properties allow for an increased operating window on the packaging equipment. Circle No. 623.

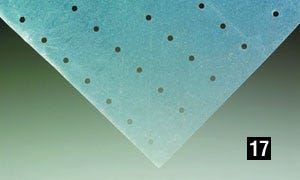

No-slip cooling for bulk carrots

Ingenious Primary GRIT Slip Sheet from Primary Packaging, Inc., is helping bulk carrot producer Timmer Farms, Imlay City, MI, stabilize palletized bags of bulk carrots (17) as well as facilitate the rapid removal of latent product heat from the stacked bags. Winner of a silver award for technical innovation, GRIT Slip Sheet is extruded from a combination of PE and a non-melting polymer to create a sandpaper effect that can hold the filled carrot bags together, while the pallet is moved and shipped.

Multiple holes in the slipsheet provide ample free space for airflow through the pallet in order to remove heat from the produce, thereby eliminating the need for Timmer Farms to place the pallets in a chiller. The Primary GRIT Slip Sheet can be supplied in single sheets or on a roll. Also, the sheets are reusable and recyclable.

Multiple holes in the slipsheet provide ample free space for airflow through the pallet in order to remove heat from the produce, thereby eliminating the need for Timmer Farms to place the pallets in a chiller. The Primary GRIT Slip Sheet can be supplied in single sheets or on a roll. Also, the sheets are reusable and recyclable.

GRIT Slip Sheet is a 2-mil, three-layer blown coextrusion consisting of a center layer of LLDPE, and outer layers of a combination of LLDPE and LDPE with an inclusion of a small quantity of an unidentified high-molecular-weight, non-melting material that provides the grit.

The film is produced on Davis-Standard equipment. The film leaving the machine is wound on a roll, which is transferred to a perforating machine that punches the holes, and also scores the film so individual slipsheets can be pulled off the finished roll by the end-user.

Primary Packaging also produces bags from the GRIT film, although this was not part of the award. The bags have the grit layer only on the outside. Circle No. 624.

Better packaging for string cheese

New England Extrusion, Inc. and Cello-Pack Corp. received a joint silver award for technical innovation for a new package for string cheese (18). Changing from a 3-mil, cast PP film to a 3-mil Inflex M0466 blown-coextruded PE film from New England Extrusion, Inc. has  offered dramatic improvement in the performance of the Sorrento Stuffsters package for string cheese, while reducing the overall cost of the package. Strength and integrity have been enhanced as a result of a new additive technology in the Inflex film that has improved seal strength and widened the heat-seal window.

offered dramatic improvement in the performance of the Sorrento Stuffsters package for string cheese, while reducing the overall cost of the package. Strength and integrity have been enhanced as a result of a new additive technology in the Inflex film that has improved seal strength and widened the heat-seal window.

The film has also completely eliminated film fractures, which occurred in approximately 10 percent of previous Sorrento Stuffster bags when made of cast PP film. Sorrento Cheese began running the new film, an extension of New England's Inflex line, about a year ago.

From a marketing perspective, the new film is robust, yet retains a soft "hand" that reminds consumers of the soft, creamy string cheese in the package. The film also achieves excellent gloss and clarity that allow consumers to clearly view the cheese product inside.

New England Extrusion manufactures Inflex M0466 film on a blown-film extrusion line from Reifenhauser, Inc. at its plant in Turner Falls, MA, and then ships the film on rolls to the Cello-Pack plant in Buffalo, NY. Cello-Pack prints the film flexographically and then converts it into open-top wicketed bags, which it ships to Sorrento. Circle No. 625.

More information is available:

Awards program: Flexible Packaging Assn., 410/694-0800. Circle No. 607.

Scavenging film: Cryovac, Sealed Air Corp., 864/433-2420. Circle No. 608.

Insulative case liner: Cargo Technology, 858/775-7079. Circle No. 609.

MAP case liner: Apio, 805/249-5212. Circle No. 610.

NesQuik shrink sleeve: Alcoa Flexible Packaging, 804/281-2262. Circle No. 611.

Fuze shrink sleeve: Alcoa Flexible Packaging, 804/281-2262. Circle No. 612.

Portion packet: Rollprint Packaging Products, 630/628-1700. Circle No. 613.

Slider pouch for carrots: Pliant, 847/969-3336. Circle No. 614.

Standup snack pouch: Printpack, 404/460-7285. Circle No. 615.

Reclosable clubstore pouch: American Packaging Corp., 215/698-4841. Circle No. 616.

Hooded slider cheese pouch: Curwood, 920/303-7362. Circle No. 617.

Disposable carafe: International Dispensing, 410/729-0125. Circle No. 618.

Slider zip cheese pouch: Pechiney Plastic Packaging, 773/399-8545. Circle No. 619.

Promotional mailer: Specialty Films & Associates, 859/647-4100. Circle No. 620.

Standup coffee bag: RJR Packaging, 336/741-2180. Circle No. 621.

EVOH barrier cheese film: Pechiney Plastic Packaging, 773/399-8545. Circle No. 622.

EZO pizza film: Pechiney Plastic Packaging, 773/399-8545. Circle No. 623.

Gritty slipsheets: Primary Packaging, 330/874-3131. Circle No. 624.

String cheese bag: New England Extrusion, 413/863-3171. Circle No. 625.

About the Author(s)

You May Also Like