Sidewall Print Adds Shelf Impact to Packs

Preprinted forming-web graphics that can replace an applied label permit eye-catching branding, a QR code, or other artwork on the side of thermoform packages.

November 4, 2020

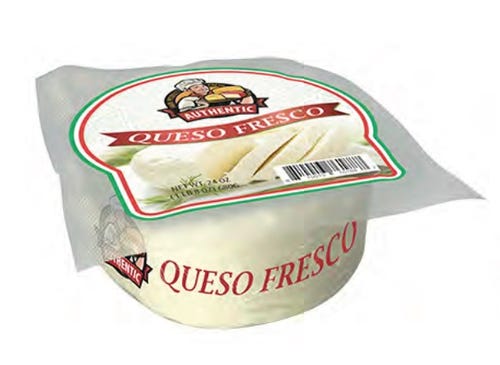

Olé Mexican Foods is a stellar case-study example of a preprinted forming film that permits branding and other graphics on the sidewall of thermoformed packaging for cheese, meat, and other markets.

In fact, the brand’s application started a trend for other brands that have since adapted the technology.

It all began three years ago after the brand consulted with its film supplier about printing on a thermoformed package and the supplier declined. When the company reached out to Sealed Air, the supplier’s graphics and packaging experts went into action to make it happen.

The preprinted graphic design on the plastic must account for the distortion caused by molding process, so the process was, time-consuming and expensive, but the tight collaboration allowed project trials to flow smoothly, and resulted in proper sizing and placement of the artwork on the profile of the queso fresco packaging.

Queso fresco, one of the most popular Mexican items, presented a unique challenge for brands that want to differentiate themselves in the highly competitive ethnic foods market where Mexican products account for more than 60%.

Olé Mexican Foods and Sealed Air worked together on this project that gives Olé’s queso fresco product instant brand recognition that no other cheese brand has. Industry research shows that 64% of consumers claim to have purchased something new because the package caught their attention, and Olé’s sales statistics support the findings.

A colorful puck.

Queso fresco is typically sold in round, puck-shaped packages with brand information printed on the top and bottom only. They are stacked atop of each other in the retail dairy case, limiting shoppers to a side view and resulting in a “sea of white” unbranded packages. Olé Foods’ queso fresco was the first Hispanic cheese product in the dairy case to let consumers see the brand without having to pick it up.

On top of a visually pleasing package with graphics that are easy to read at a distance, Olé’s product has immediate and unique brand recognition.

Olé applied the new packaging to two different brands and a total of eight SKUs, resulting in a 16% or $1.5 million increase in sales over an 8-month period.

Olé is consulting with Sealed Air to solve more challenges and deliver industry-changing innovations.

“We couldn’t be more pleased with the visibility and recognition the new packaging has given us in the marketplace,” says Blake Johnson, vice president at Olé Foods. “Our product now has the differentiation that none of our competitors has. If you take a photo of the Hispanic cheese section, you’ll see a sea of white, with our product being the only one that stands out.”

Trend-setting, trend-enabling innovation.

“This solution has sparked a lot of interest in the cheese and processed meat markets in North America and has even expanded into the Latin American market,” says Deborah Sepulveda, North America director, SEE Graphic Services at Sealed Air. “For products that are stacked on top of each other at the retailer, Formed Profile Printing offers the processor increased brand awareness for targeting their consumer base. It enables processors to change their packaging format style from a flow wrap to a traditional rollstock package, while obtaining ink coverage around the entire package to potentially improve overall product quality by complete air removal in the package. It’s a pathway for further brand building, increased consumer awareness, and additional opportunities for messaging.”

Sealed Air prints the forming film using a standard flexographic plate in a multicolor process print at high-definition resolutions. The company can also print the film digitally sans plates.

It can replace an applied label to save material and one step — label application — on a production line.

“This also enables future recycling by reducing the amount of mixed plastics for a package,” Sepulveda points out.

According to Sepulveda, the technology is also an on-trend enabler for today’s consumer: By reclaiming often unused package space for print and branding, there is more space for graphics including Quick Response (QR) codes or other scannable features that enable connected packaging for direct consumer engagement.

The preprinted rollstock works with any horizontal thermoforming machine that has a registration system for the forming web.

“Our focus has been on flexible and semirigid packaging materials used in horizontal form, fill, and seal applications,” says Sepulveda. “This technology works for most materials and thermoforming equipment that have a predictable and repeatable distortion pattern during the forming process. There is also advanced technology in the ink system to withstand the temperatures material is exposed to during the forming process.”

Although the technology has changed little since 2017, Sealed Air “continues to test different shapes and draw depths to see how else we can expand our offer,” Sepulveda adds.

You May Also Like