Non-biodegradable bioplastics lead market growth

January 30, 2014

An above-average positive development in bioplastics production capacity has made past projections obsolete. The market of around 1.2 million tonnes in 2011 will see a fivefold increase in production volumes by 2016—to an anticipated almost 6 million tonnes. This is the result of the current market forecast, which the industry association European Bioplastics publishes annually in cooperation with the Institute for Bioplastics and Biocomposites from the University of Hannover.

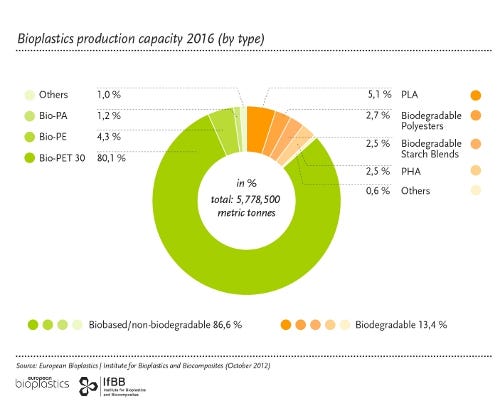

The worldwide production capacity for bioplastics will increase from around 1.2 million tonnes in 2011 to approximately 5.8 million tonnes by 2016. By far the strongest growth will be in the biobased, non-biodegradable bioplastics group. Especially the so-called "drop-in" solutions—that is, biobased versions of bulk plastics like PE and PET—that merely differ from their conventional counterparts in terms of their renewable raw material base, are building up large capacities. Leading the field is partially biobased PET, which is already accounting for approximately 40 percent of the global bioplastics production capacity. Partially biobased PET will continue to extend this lead to more than 4.6 million tonnes by 2016. That would correspond to 80 percent of the total bioplastics production capacity. Following PET is biobased PE with 250,000 tonnes, constituting more than 4 percent of the total production capacity.

"But also biodegradable plastics are demonstrating impressive growth rates. Their production capacity will increase by two-thirds by 2016," states Hasso von Pogrell, managing director of European Bioplastics. Leading contributors to this growth will be PLA and PHA, each of them accounting for 298,000 tonnes (+50 percent) and 142,000 tonnes (+550 percent) respectively.

"The enormous growth makes allowance for the constantly increasing demand for sustainable solutions in the plastics market. Eventually, bioplastics have achieved an established position in numerous application areas, from the packaging market to the electronics sector and the automotive industry," says von Pogrell.

Bioplastics share of material types 2016

A disturbing trend to be observed is the geographic distribution of production capacities. Europe and North America remain interesting as locations for research and development and also important as sales markets. However, establishment of new production capacities is favoured in South America and Asia.

"European Bioplastics invites European policy makers to convert their declared interest into concrete measures. "We are seeing many general supportive statements at EU level and in the Member States," says Andy Sweetman, chairman of European Bioplastics. "There is, however, a lack of concrete measures. If Europe wants to profit from growth at all levels of the value chain in our industry, it is high time the corresponding decisions are made."

For a more in-depth impression of the world of bioplastics, visit the 7th European Bioplastics Conference on Nov. 6-7, 2012, in Berlin. With more than 400 experts on hand, the European Bioplastics Conference is the leading industry event in Europe.

Market data charts can be downloaded in English and German here at http://en.european-bioplastics.org/press/press-pictures/labelling-logos-charts.

Moreover, deeper insights and extensive additional data are provided in the complete market study of the Institute for Bioplastics and Biocomposites of Hannover University. These will be available at the institute soon.

Source: European Bioplastics

.

About the Author(s)

You May Also Like