Brew with a view

Brew with a view

A new $21 million, 75,000 sq-ft craft brewery recently built by New Glarus Brewing Co. in New Glarus, WI, can produce 100,000 barrels of beer/year. Founded in 1993, the company brews a variety of beers with its Spotted Cow label leading in sales. The new facility, which is built on a hilltop, was designed to look like a Bavarian village and is a popular destination for visitors. The facility includes an expanded brew house with Steinecker brewing technologies and a completely new 310 bottle/min packaging line.

An interesting marketing model of the company is that it sells its products only in Wisconsin and has no intention to extend sales of its craft beers beyond its native state. New Glarus had distributed its products briefly in Illinois early in its existence, but after some distribution issues, it ceased sales in Illinois and never returned. "We can barely keep up with demand in Wisconsin, even with our new facility, so there is no reason to distribute outside the state,' says founder and president Deborah Carey. "Our Wisconsin customers have been very loyal to us, and we feel a great allegiance to our home state."

Brew with a view

Glass walls allow easy viewing

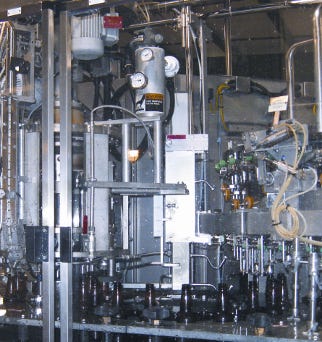

The bottling line at New Glarus is enclosed by glass walls that enable tourists to easily view the operation. To start the process, workers place cases containing 24 empty bottles on a conveyor that delivers them to a CamPac machine from Krones Inc. that lifts the empty bottles out of the cases and places them on a discharge conveyor. The bottles are supplied by O-I. Filled and labeled bottles are delivered to the unit on a parallel conveyor, and the machine picks up these bottles and places them into the shipping cases on an alternating cycle. The machine picks up the bottles with pneumatic grippers that descend over the tops of the bottles and grasp the necks.

The bottles leaving the decaser are conveyed past an accumulation table and then are single filed as they travel to the Krones rinser/filler/crowner. This monobloc system consists of a 60-valve Variojet rinser, a 40-valve VK2V counter-pressure filler and a 10-head crowner. Bottles are transferred into the rinser by a screw and infeed star wheel. Plastic clamps grasp the bottles at the neck and the body and swing them upwards through 180 deg as the turret rotates. Spray nozzles positioned directly beneath the neck finish injecting the rinsing medium into the bottles.

Brew with a view

The bottles are then returned to the upright position and are transferred through the discharge star wheel onto the conveyor. A screw mounted beside the conveyor maintains the precise spacing of the bottles as they travel to the filler, where they enter through another infeed star wheel.

Low-oxygen filling

The Krones VK2V filler, which is specifically designed for beer, incorporates a vacuum feature that enables double pre-evacuation of the bottles, thus assuring low oxygen pickup during the beer bottling operation. As a bottle enters the rotating turret, the pneumatic lifting cylinder presses it onto the filling valve until a gas-tight seal is formed. This connects the bottle to the ring bowl. In this position, the gas needle and the product stem in the filling valve are closed. Following an electronic pulse, the vacuum valve opens and draws a vacuum that reduces the percentage of air in the bottle to about 10 percent.

Brew with a view

The mechanically controlled gas needle then opens the connection to the ring bowl and carbon dioxide flows into the bottle, after which the mechanically controlled vacuum valve opens again, producing another vacuum within the bottle. This reduces the air concentration in the bottle to approximately 1 percent. The gas needle then opens and admits the gas mixture from the ring bowl, through the vent tube, into the bottle. As soon as the pressures in the bottle and the ring bowl are equal, the product stem opens and filling begins.

The product flows along the vent tube into the bottle, and a small spreader mounted on the vent tube guides the liquid to the bottle's inner sidewall, thus ensuring a gentle product flow.

After a short settling phase, the snifting valve opens the connection to the clean-in-place channel, which allows the pressure in the bottle to equalize with the outside atmospheric pressure, after which the bottle is lowered and transferred to the discharge star wheel.

Brew with a view

Cold-glue labeler

Bottles leaving the filler travel onto an infeed star wheel that delivers them into the crowner. Crowns are dumped into a floor hopper, travel up a magnetic elevator to an overhead sorter/feeder. The crowns then travel down a chute to a transfer plate where they are precisely centered on the mouth of the bottle. A bottleneck centering system for the bottles entering the crowner ensures that even bottles with inaccurate dimensions are reliably sealed. The crowns are positioned on the head, which lowers as the machine rotates, until the closing ring presses it onto the bottle mouth. When the crown is secured, the lifting cam raises the crowning head, and the bottle discharges from the machine through a star wheel.

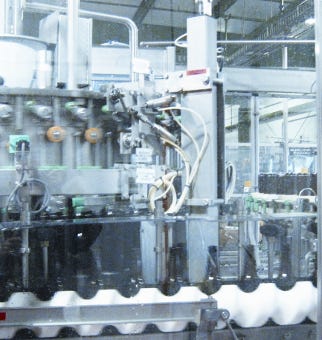

The bottles leave the crowner single file, travel past an accumulation table and then enter a Krones Starmatic cold-glue labeler that applies a single body label and a neck label. Labels are supplied by Inland Label & Marketing Services. A feed screw meters the bottles into the labeler's infeed star wheel, which, in turn, transfers the containers to the revolving container table, where a centering bell at each descends to hold the bottle in place as the label is applied. The unit is equipped with two labeling stations to apply front and neck labels. In each labeling station, a rubber-coated glue pallet is given a very thin film of glue from a gluing roller made of hardened steel.

Brew with a view

The pallet then picks up a label from a magazine, applies the film of glue to the label and transfers the label to the gripper cylinder, which places the label precisely on a container as it passes by on the rotating container table. The label is held in place on the container while being smoothed out with a brush and sponge roller. The labeled containers discharge through a star wheel onto the takeaway conveyor, and are transported through a fill-level inspector from Teledyne Taptone. This is followed by a vision inspection system that checks the labels.

Brew with a view

A Series A300 inkjet printer from Domino Amjet Inc. applies the date and lot code to shoulders of the bottles, after which they are conveyed to the CamPac unit described previously, which places the bottles back into the shipping cases.

Brew with a view

The filled cases are conveyed to a top sealer that applies glue from a Nordson Corp. hot melt unit. A Domino Amjet Model C3000+ inkjet printer then prints the variety and lot code to the case. The cases are conveyed to a Model FL10 floor level palletizer from Columbia Machine Inc. The pallets are stretch wrapped by a unit from Wulftec Intl. Cases conveyors are supplied by Hytrol Conveyor Co. Six pack carriers are supplied by Gamer Packaging Inc.

Columbia Machine Inc., 360/694-1501.

www.palletizing.com

Domino Amjet Inc., 847/244-2501.

www.dominoamjet.com

Gamer Packaging Inc., 612/788-4444.

www.gamerpackaging.com

Hytrol Conveyor Co. Inc., 870/935-3700.

www.hytrol.com

Inland Label & Marketing Services, 608/788-5800.

www.inlandlabel.com

Krones Inc., 414/409-4000.

www.kronesusa.com

Nordson Corp., 770/497-3700.

www.nordson.com

O-I, 567/336-5000.

www.o-i.com

Teledyne Taptone, 508/563-1000.

www.taptone.com

Wulftec Intl Inc., 877/985-3832.

www.wulftec.com

About the Author(s)

You May Also Like