'Green Methanol' Is the Packaging Industry’s Future

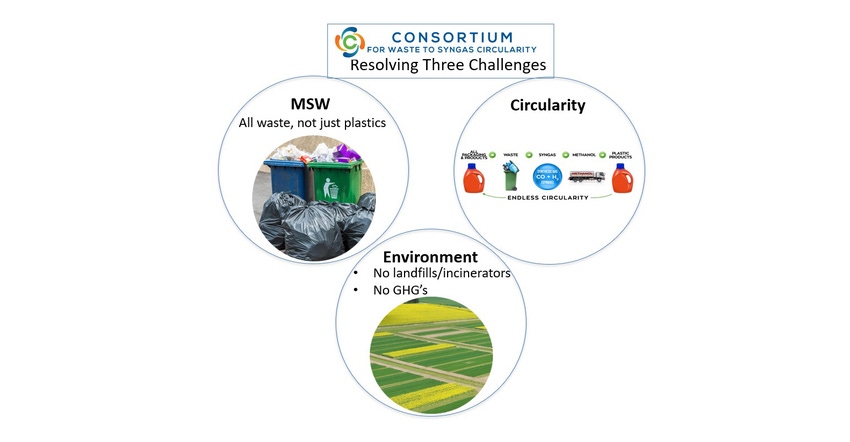

Why brands and suppliers should support converting waste to synthesis gas to “green methanol” via the Consortium for Waste to Syngas Circularity.

Consumer packaged goods (CPG) companies have pledged to boost use of recycled content and fallen short to meet their pledges promised time after time as recycled materials are unavailable. The recycling pledges made for 2025 are proving to be, once again, unrealistic and unachievable declarations.

According to Closed Loop Partners, the current supply of recycled plastics would meet just 6% of companies pledged goals. Continuing failed approaches doesn’t lead to a path for success. It is time for disruptive transformation to allow these inspirational goals to be met.

Transform All Waste, Not Just Plastics.

Today the packaging industry is finding itself needing to manage fake news and scientifically unwarranted social media hype that plastic is harmful. This situation is causing CPGs and packaging Suppliers to scramble and many industry players are darting in different and short-term directions in the hope of avoiding being a target of negative publicity. Short-term thinking is exacerbating problems with waste and recycling while avoiding the facts that CPGs need to grow and that they will continue to need a variety of packaging materials including plastics. The problem will not be solved through bans and taxes. We need robust and agile solutions that can handle existing and ongoing innovation that leads to growing diversity of packaging materials.

The packaging industry is diverging in approach to the problem with solutions such as:

• Improving mechanical recycling

• Compostable solutions

• Biodegradable materials

• Monolayer structures

• Conversion to alternates paper/glass/cans

While these approaches can all be valuable, in many cases they can only produce incremental short-term gains for short-lived feel-good headlines. But more often than not, the problem is made worse by substituting a plastic packaging material that can potentially be recycled, with alternative materials that are perceived as environmentally friendly but which have fewer end of life recovery options. A focus on short-term solutions fails to address the larger, more comprehensive environmental problem. The real problem that needs to be addressed…how to deal with all waste, not just plastics.

Birth of a Consortium.

The Consortium For Waste To Syngas Circularity was created from packaging industry visionaries who not only see the need but also voiced the need to stop the “self-serving and feel good” divergent talk and take action. They also recognize the need for new robust solutions that permit ongoing innovation and material diversity in packaging. These early founders of CWSC believe the packaging industry needs a common goal and science-based technical solutions to solve the problem created from all packaging waste. The recent pandemic accelerated the ecommerce trade. This resulted in more packaging than ever before and brought to light societal dependence on packaging for safety and medical needs. Additionally, the reality of the interconnectedness of land, climate and ground water highlights the importance of a major transformation needed in dealing with all the problems of waste.

After several industry summit meetings of CPG brand owners, printers, packaging suppliers and academia in 2019 and early 2020 it was clear there was a need to change the course. A grass roots movement was born with the formation of the Consortium for Waste to Syngas Circularity (CWSC). Its vision is to transform waste handling over the long-term by adding advanced recycling technologies as the backbone of our waste handling solution in the portfolio mix of the packaging industry.

CWSC’s Purpose.

The purpose of CWSC states, “We envision a world without waste, in which waste is treated as a valuable resource. We seek to end the practice of landfilling and incineration, favoring processes that support circular economy sustainability. We envision a world where molecules derived from nature’s precious resources can be used and reused in an endless loop of circularity”.

CWSC aims to achieve its purpose by doing the following:

• Align the industry toward a total transformation for all waste, not just plastics

• Embrace a path of true circularity for waste respecting land, ground water & climate without compromise on quality of recycled materials

• Advance “green methanol” from waste as the primary vehicle for integrating “recycled content” into products and packages from science-based waste to syngas to methanol process

The purpose of CWSC includes supporting, scientific research, education and outreach creating innovative approaches to promote investment by municipalities in robust advanced recycling infrastructure required for the conversion of consumer waste into valuable recycled content feedstock materials for manufacturers. This results in environmentally friendly, clean, virgin materials useable and affordable for manufactured goods. The packaging industry would follow a route of all waste to syngas to “green methanol” and back to waste.

The Consortium for Waste to Syngas Circularity image shows how waste can be converted into synthesis gas, methanol, and then back into virgin

Converging on a circular solution.

Unless the packaging industry acts together toward a long-term solution for the benefit of present and future generations, we will continue to be stuck with incrementalism that does not move the needle much to improve public health or the environment. CPG’s and Packaging Suppliers will continue to be blamed for the problem down the road. The packaging industry needs alignment on a bodacious problem definition of transforming the entire waste management infrastructure. This will address the current issues of landfills, incineration, climate change and risk to ground water contamination while providing “green methanol” to be used for packaging.

CWSC intends to do for the packaging industry what the airline industry has been keen to do for itself. Airlines have not only committed to being carbon neutral by 2050 but have aligned on a long-term action plan to achieve this goal. Using the world’s most abundant resource…household garbage and converting this waste to syngas and into biofuels will provide “green aviation fuel” for the airlines. Such facilities are already being built in the US, Canada, UK and Europe by Fulcrum BioEnergy to begin the necessary infrastructure. The airlines are making pledges to use this fuel and in doing so they are pulling on the technology to make this possible. The packaging industry can and should be doing the same. Brands and suppliers should be aligned to convert waste to syngas to “green methanol” and make pledges against using such a recycled resin, free of fossil fuels.

The production of methanol is a well-established feedstock chemical that’s produced globally. Methanol is important and considered a base component in the production of plastics, synthetic fibers, fibers to make clothing, paints, adhesives, pharmaceuticals, agricultural chemicals, and many other products. The use of “green methanol” will provide a pathway for incorporating increasing amounts of recycled content in virtually all manufacturing and improve the environmental impact of any of these end products.

A registered non-profit, CWSC has recently launched a website explaining the purpose, science, technology and mission.

The CWSC has a Board of Directors in place and is guided by a growing Academic and Public Affairs Committee created to provide scientific guidance by members Dr. Bruce Welt, University of Florida & Dr. Calvin Lakhan, York University. The recently announced Public Affairs Committee is led by Ted S. Yoho, DVM and Former Member of Congress. Additional articles and presentations are available on the website for further perspective and background.

CWSC encourages all companies, CPG’s, Package Printers and Packaging Suppliers seriously interested in achieving circular economy sustainability to join and to add their voice. Each new member of the Consortium brings closer the realization of this important transformation.

The CWSC doesn’t take away from any of the short-term efforts CPG’s and Suppliers are undertaking but to provide an additional long-term approach and vision. A waste to syngas to “green methanol” process replacing landfills & incineration will ensure a true disruption. All those difficult to recycle products and packages (eg: diapers, multilayer bags, toys, electronics, medical waste, etc.) that are organic are rich in carbon and hydrogen can be extracted and returned for valued reuse. This robust and agile technology approach removes the confusion from consumers caused by today’s recycling infrastructure ensuring all waste is processed. The CWSC sustainable approach combines all of the economic, environmental and social benefits to serve the generations to come. We are all in this together to change the current status quo and look forward to a conversation toward collaboration.

Authors

Mike Ferrari completed a successful 32-year career at The Procter & Gamble Co. where he started the Global Printing & Decoration Department. He founded Ferrari Innovation Solutions, a Brand Packaging Consultancy. Through an understanding of end-of-life issues surrounding all packaging materials, Ferrari has dedicated his efforts to the transformation of all waste that creates circularity. Ferrari is President of the Consortium For Waste To Syngas Circularity.

Janice Loppe is the Senior Director of Sustainability for Intertape Polymer Group (IPG), a global leader in packaging and protective solutions. Prior to her current role, she served as the Senior Director of Business Development at IPG where she managed the company’s market research team, led the business planning function and supported the commercial aspects of the company’s M&A projects. Janice serves on the Board of Directors for the Consortium For Waste To Syngas Circularity.

Jason Vande Loo is the managing Director of New Business Development for Strategic Markets and Products at Belmark Inc. Jason has 20 years’ experience in the packaging industry and has held senior management positions leading product development and research engineering teams driving “new to the world” converting technologies and innovative products. He is responsible for new market strategies, commercialization and penetration to drive growth for both Belmark and their customers. Jason serves on the Board of Directors for the Consortium For Waste To Syngas Circularity.

About the Author(s)

You May Also Like