Does this often-overlooked sustainable packaging metric deserve more attention?

When deciding the size of a product’s package—single serve versus multiserve or 12 versus 16 ounces, for example—brands typically consider consumer convenience, optimum shelf display or profitability. But perhaps sustainability should be higher up in that list. Here’s why.

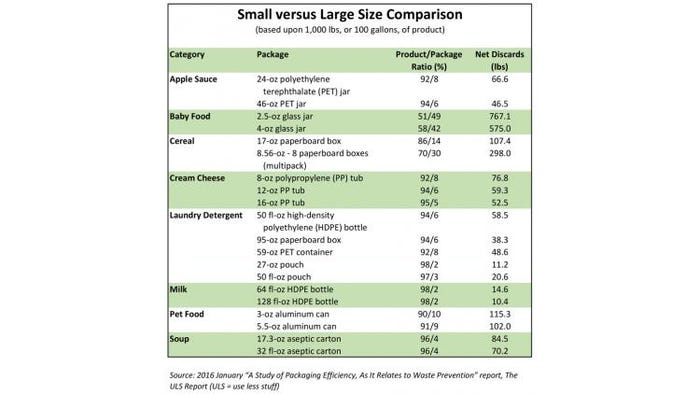

“Larger product/packaging sizes are significantly more efficient than their smaller counterparts, regardless of material type.” This is one of five major findings in the 20th Anniversary Edition of “A Study of Packaging Efficiency, As It Relates to Waste Prevention” report from the editors of The ULS Report (ULS = use less stuff).

This conclusion is consistent with the two earlier groundbreaking studies done by ULS in 1995 and 2007. But the world has changed considerably, especially since the first study. It’s “greener” than it used to be. Not many packaging or marketing professionals talk about the product-to-package ratio, but it can be a critical measure of a product’s sustainability. And, intuitively, consumers often sense when the ratio is woefully out of whack, incorporating that into their purchase decision.

For foods or beverages, this ratio is just one aspect of a larger sustainability and packaging efficiency discussion. As the name of the report implies, waste prevention can be directly connected to sizing a package appropriately for the product’s use and the consumer’s lifestyle. Too big and the food might spoil before it can be completely eaten. Too small and you could be generating more packaging waste than your customers will accept.

How does package size compute when taking into consideration product waste? Robert Lilienfeld, ULS editor and Packaging Digest contributing writer, says, “The odds are good that larger sizes would generate more waste, if purchased by price per ounce rather than the number of portions needed.”

What if the number of portions needed is one, though? Aren’t single-serve packs inefficient from an overall sustainability perspective (energy used to produce, for example), not just looking at the product-to-package ratio? That’s what makes this a rather complex issue, despite the simplicity implied by the numbers. Portion control can aid consumers’ health/weight goals, provide hygienic assurance and enable on-the-go consumption or use—conveniences that often out-weigh sustainability objectives. “These consumer factors can be at least as important from an overall sustainability standpoint, compared to only looking at packaging-related information,” says Lilienfeld.

Let’s take a look inside some actual numbers.

This latest ULS report measured the product-to-package ratio and net discards in pounds for seven different foods. The numbers reported assume at-home use and disposal. What about away-from-home situations, which could represent a significant effect because of today’s on-the-go society? How might that skew the ratios and discard numbers? “The logical effect is that efficiency goes down for out of home, as the recycling rate would decline,” Lilienfeld explains.

The examples in the table below highlight how much more efficient large sizes can be than their smaller counterparts.

In most instances, the larger the package, the higher the product-to-package ratio. In two cases—for milk in high-density polyethylene bottles and soup in aseptic cartons—the ratio stays the same regardless of the package size. “Both sizes are large enough that efficiency is about equal,” Lilienfeld explains. “This is also due to rounding. For soup in aseptic cartons, the larger rounds down to 96% and the smaller rounds up.”

The multipack effect, shown in the cereal category, shows how this portion-control and on-the-go convenience takes a major sustainability hit.

And while larger sizes are more efficient despite the type of packaging material, material choice does influence the amount of net discards. Glass, not surprisingly, ranks highest by weight. Flexible packaging, as expected, often logs on the lowest end of the spectrum of discard weight.

Lilienfeld also points out how some product innovations, like the Tide Pods, create a product/package system that makes a sustainable comparison to the previous or competitive packages difficult. The newer product, detergent/stain remover/brightener-in-one, replaces two separate products (detergent and bleach), each in its own package. Additionally, the newer products are highly concentrated, saving more space and needing less packaging material to contain.

This type of product/package innovation—while a win-win in consumer convenience and sustainability—is the outlier. The report deduces that “Ultimately, packaging decisions are driven by consumer perceptions and lifestyle requirements. In many cases, these factors lead to more packaging rather than less.”

Two reasons support this conclusion (as cited in the report):

• “We tend to equate quality with quantity. A 500mL bottle of store brand water weighs 8.8 grams and has a retail price of $0.13. A 500mL bottle of a typical ‘performance brand’ weighs 27.3 grams and retails for $1.19. While the latter’s heavier weight and higher prices may increase quality perceptions among users, they generate greater environmental and economic costs for society.”

• “We strive to achieve active, healthy lifestyles. This state of mind leads to the demand for packaging to deliver convenience, ease of use and portion control. Resulting packaging responses generally lead to inefficiencies, as they require smaller sizes or the increase functionality needed to deliver ready-to-eat, ready-to-serve and out-of-home product solutions.”

This is just a mere sample of the compelling data in the full 60-page report, published January 2016, which you can download for free. It includes expert analysis on five major findings, as well as raw data for 300+ products in more than 50 different product categories.

This is the level of detail I’ve come to expect, trust and appreciate from studies done by the leading consumer testing and rating magazine Consumer Reports.

______________________________________________________________

Learn about the latest developments in sustainable packaging at WestPack 2016, Feb. 9-11 in Anaheim, CA.

______________________________________________________________

About the Author(s)

You May Also Like