Automation drives efficiency, lowers cost for case packer

|

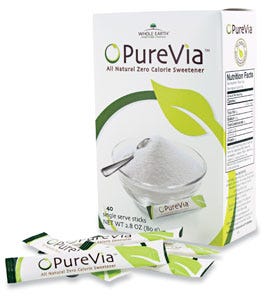

Merisant was formed in March 2000 to manufacture and market the tabletop sweeteners, Equal® and Canderel®. In December 2008, it launched PureVia™, an all-natural, zero-calorie sweetener made from the sweet leaf of the stevia plant.

When Merisant decided it needed to replace an existing case packer last year, the Model P200 unit from Serpa Packaging Solutions seemed to be an obvious choice. “We had installed two P200 case packers in 2004, and they have done a superb job for us, so they were certainly at the top of our list. But we still needed to see what else was available,” says plant engineer J.T. Washington. “We looked at a number of case packers from other manufacturers, and I took some of my mechanics to the PACK EXPO show, because I wanted everyone to be involved with our decision to install another P200.”

|

The seven-axes, servo-driven casepacker can pick and erect 20 cases/min. The balcony design provides convenient, full walk-in acccess to all of the components. |

Designed for pharmaceutical, nutraceutical, personal care and medical device packaging, the P200 is an advanced, seven-axes, servo-driven case packer that can pick and erect 20 cases/min. It was the first balcony case packer designed and built in the U.S. Instead of a conventional frame design, the balcony design uses a pair of bifold doors that open up to provide convenient, full walk-in access to all of the drive components from the operator side of the machine.

“In addition to our satisfaction with the machines we had, there were other factors that definitely affected our decision to buy another P200,” says Washington. “One was size. We needed to fit the case packer into a very narrow space, and the other machines were all too wide. In addition, the P200 is 13 feet shorter than the machine we had, so that gives us more room on the line. Another advantage is it's so easy to get into the machine. With the balcony design, the doors open wide, and the machine has a quick-release gate that opens so that jammed cases will just drop onto the floor and can be easily removed.”

Designed for easy access

The old saying, “If it ain't broke, don't fix it” is a philosophy many companies apply in their product-development plans. Serpa Packaging Solutions, however, isn't your typical company. Ever since Fernando Serpa began making end-of-line packaging machinery in 1981, the company based its philosophy on trying to improve upon its existing products. That's why Serpa reintroduced its signature P200 balcony case packer.

|

Cases are taped shut as they leave the |

Serpa turned to Bosch Rexroth Corp. to provide product expertise and applications support for an integrated-electric drives, control and linear-motion solution. To help reduce costs and improve machine efficiency, Serpa also collaborated with local automation distributor Applied International Motion to specify and implement the Bosch Rexroth motion- and servo-control system.

According to Serpa, the P200 is the first case packer to be able to run cases and trays on the same machine. The machine collates the product to achieve the correct pattern, loads the product into a case or tray and seals and discharges it. The servo-controlled erector has two camshaft profile axes that drive a parallel-link arm. The arm picks up the case and erects it in the same area where the loading takes place.

Because the loading and case erection occur in the same area, this reduces the overall footprint and maximizes the speed of the P200. The standard-machine footprint is only about 8 ft long and 6.5 ft wide.

|

Twelve cartons are assembled into a group, which is then pushed into the open end of a corrugated shipper. |

Using Rexroth servos helped simplify the overall design for easy access and a smaller footprint. For the P200, Serpa opted for Rexroth's IndraDrive intelligent digital servo drives, IndraDyn servo motors, and a linear Ball Rail® system. The motion and logic was programmed with Rexroth IndraWorks software. “We've been very satisfied with the IndraDrive servos and other Rexroth components on the other Serpa machines, so we made sure that they were also installed on our new machine,” says Washington. “The Rexroth servos give us much fewer problems than other servos we have installed here.”

Instead of a mechanical drive, Serpa used Rexroth's servo system to create an electronic line shaft with cam-profile movement. The P200 uses multi-axes synchronization with the ability to change motion profiles on-the-fly. Of the seven axes, four are synchronized using electronic cam shafts and three are point-to-point axes. To achieve proper forming of the case, the erector and walking-beam motion are tightly synchronized through SERCOS III communication with the Rexroth IndraDrives. The drives use cross-communication linking, with only one drive needing a fieldbus interface. The other drives use SERCOS to communicate to the PLC from the master drive, no matter which fieldbus is chosen.

According to Bosch Rexroth, the powerful and cost-effective IndraDrive servo drives are unique, because they offer many advanced features, including distributed intelligence, to close all the loops in the drive. The drives also provide 230-to 480-V AC auto-ranging input, absolute feedbacks to eliminate homing and a built-in personality module or SD memory card for laptop-free replacement in minutes. The drives can store up to eight electronic cam profiles of 1,024 points each. The IndraDrive servo drive's internal virtual master axis and precise synchronization allow smooth motion, even while the machine is running at high speeds. This reduces the loads placed on the mechanical parts of the machine, which provides a high level of reliability.

|

The case packer uses a servo system to |

All motion and programmable limit switch outputs are based on a virtual master axis. Serpa also used Rexroth IndraDyn synchronous motors, which offer complete scalability and compact construction with increased torque density, absolute encoders and high-resolution resolvers. To handle the engineering/programming, Serpa and AIM used Rexroth's IndraWorks software suite, which was vital to building the types of cams that were needed.

With project planning, programming, parameterization, visualization, operation, diagnostics and maintenance capabilities all in one package, IndraWorks is a single engineering suite for data management and open communication that covers the entire range of engineering tasks and tools.

|

A linear ball-rail system with high rigidity helps to reduce deflection of the machine components. |

In addition to servo control, smooth linear motion was also necessary for the P200. Serpa chose a Rexroth linear Ball Rail system to help ease the load. The cantilever design of the balcony case packer causes large moment loads on the linear bearings. Rexroth linear Ball Rails have very high rigidity and help reduce deflection of the machine components. This leads to increasing reliability of the machine, allows for higher speeds and helps axes run smoothly at higher speeds. The Ball Rails also help to lower maintenance. With lube reservoirs located inside the runner block, the Ball Rails do not need to be lubricated as often, which helps to reduce maintenance costs.

Reduced installation and startup time

Rich James, Serpa's director of marketing, says Bosch Rexroth components helped Serpa develop a precise machine that offers scalability, straightforward programming, easy startup and the versatility to run off of an internal controller or in combination with any external PLC. “Other servos did not solve our automation needs as efficiently or as cost-effectively as Bosch Rexroth,” explains James. “Bosch Rexroth has supplied a solution for our machines that is not only easy to program and start up, but saves time and money.”

By opting for a Rexroth drive and control system over other controls suppliers, James says Serpa reduced its installation and startup times by 30 to 35 percent. In addition, Serpa was able to use 25 percent fewer parts on the P200 compared to their previous model, because it now uses fewer drive components and fewer cables.

“Besides reducing the part count, another advantage Rexroth provided was helping with rapid changeover,” says James. “We can do a rapid, no-tools changeover in five minutes or less.” The fast changeover is attributed to the ease of switching axes to different electronic cam shaft profiles.

James adds that the scalable design of the IndraDrive allows Serpa to purchase only the exact features they need. Because of the IndraDrive internal virtual master and limit switch, it eliminates the need for an external limit switch and master encoder. Using a Rexroth drive and control system equated to a significant cost savings. “Overall, with Bosch Rexroth, our hardware costs per machine are almost 40 percent less than with other brands we've used at Serpa,” said James. “We're very happy with the final machine and the benefits of the control and linear motion system.”

More information is available: |

Bosch Rexroth Corp., 800/739-7684. www.boschrexroth-us.com |

Applied International Motion, 909/593-7304. www.aimotion.com |

Serpa Packaging Solutions, 559/651-2339. www.serpapackaging.com |

About the Author(s)

You May Also Like