Innovative air cushion solution improves productivity, reliability and cost.

March 11, 2015

By Michael Guelker, Product Manager, Pneumatic Actuators, Festo USA

A common goal throughout the busin

rrrrAdjustable-air-cushioning_Img-1.jpg

ess world is to increase productivity while reducing costs. This certainly applies to machine design, which means achieving the fastest possible cycle times. For pneumatic systems, this often requires running actuators as fast as possible without introducing excessive shock loads to the system.

To help reduce the impact energy of an actuator, there are two common types of integrated cushioning - bumpers and air cushioning. Flexible bumpers are generally made of an elastomer material and incorporated as part of the piston or end cap. They effectively reduce impact noise; however, they can only absorb small amounts of energy so they are limited to slow speed, small load, or short stroke applications.

When operating with higher loads and speeds, you

rrrrAdjustable-air-cushioning_Img-2.jpg

must use additional cushioning in order to avoid premature damage to the cylinder and machine. Designers generally use air cushioning for end-of-stroke damping in these situations. The air cushioning needle valve needs to be adjusted according to the cylinder's operating pressure, speed, and load.

This requires the time of one or two experienced maintenance people, which is costly. If there are any changes to the air pressure, speed, or load, then the air cushioning needs to be re-adjusted, otherwise the machine may experience slower cycle times and increased shock and vibration, which will cause premature failure of the cylinder and potentially other components on the machine.

A new air cushioning solution (PPS) has been developed by Festo that automatically adjusts the amount of air cushioning depending on the impact energy (speed, load), thus increasing overall productivity and reducing maintenance co

Adjustable-air-cushioning_Img-3.jpg

sts.

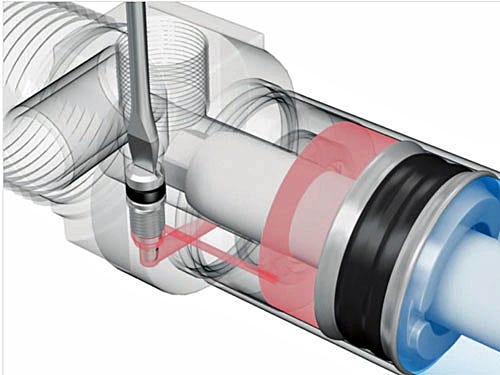

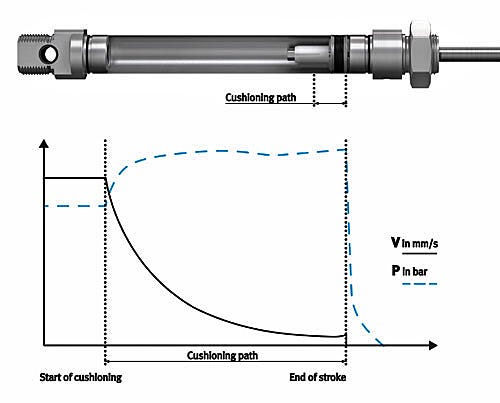

Before we review the details of the design and operation of the new self-adjusting air cushioning, we will look at the principles behind air cushioning and the operation of typical adjustable air cushioning. Air cushions are variable-orifice air dashpots. A spud on either side of the cylinder piston closes off the passage to the main piston chamber. This traps air in the cylinder end cap and bleeds it off through a small passage controlled by a needle valve. The cylinder traps a fixed volume of air each cycle, but because air is highly compressible, the load, velocity, and air pressure in the cylinder all affect air-cushion performance.

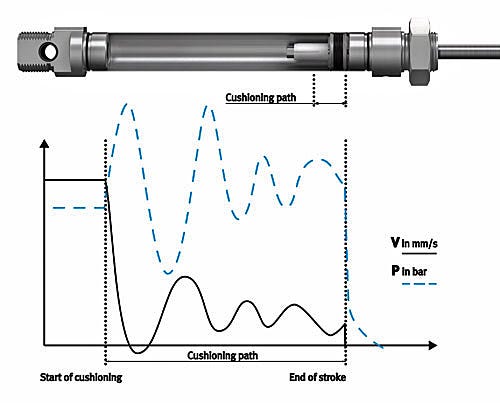

For any given set of conditions there is generally only a small window of needle-valve adjustments that provide optimal cushioning. Closing the needle valve too far results in high initial reaction force, which slows the load too quickly. This may cause end-of-stroke bounce, which is when the piston changes direction multiple times as deceleration progresses, causing vibration and a longer cycle time.

If the needle-valve is open too far, the trapped air does not create sufficient back pressure. The load reaches the end of stroke too quickly and causes an impact between piston and end cap. Furthermore, once the needle-valve is properly set, any change in weight, system pressure, or velocity affects cushion reaction, and means the valve must be readjusted.

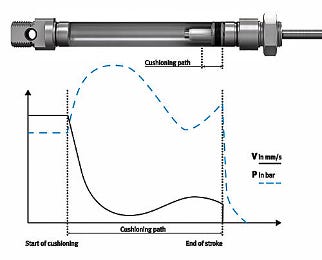

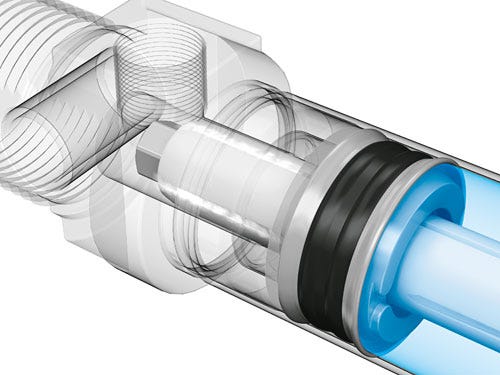

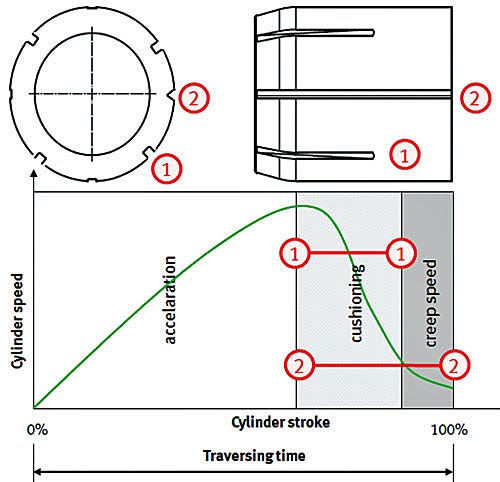

Self-adjusting cushioning is a new type of cushioning system that eliminates the need for manual adjustment of the cushioning. In principle, it works the same way as manually adjustable cushioning, but the cushioning chamber is not exhausted via an adjustable cross-section (PPV adjusting screw) but via notches in the cushioning piston. The know-how lies in the geometry of these notches.

Long

Adjustable-air-cushioning_Img-6.jpg

itudinal slots integrated into the cushion pi

zzzAdjustable-air-cushioning_Img-7.jpg

ton make it possible to exhaust the air cushion independent of the cushioning length. The system employs innovative, patented air channel geometry to provide phased venting of the cushioning air. The system automatically adapts its characteristics to suit the cylinder's prevailing load and speed conditions to provide optimum end-position cushioning.

Because the exhaust flow of the pneumatic cushioning chamber changes over the damping stroke, it works with most commonly permissible speed and mass combinations, making it suitable for a wide range of applications.

The advantages of self-adjusting end-position cushioning are considerable. Manually adjusting the end-position damping of linear actuators is time-consuming and can only be done effectively once the actuator is installed and under operating load conditions. By then the automation supplier is invariably under pressure to complete the task as quickly as possible.

It also frequently involves two people - one to operate the appropriate pneumatic valve, the other to adjust the actuator's damping characteristics. As with all moving parts, access can be potentially hazardous, which means that safety considerations dictate that only experienced personnel should perform these adjustments. Actuators are often less than perfectly adjusted, with under-damping resulting in higher end-position impacts, higher noise levels and increased wear, or with over-damping resulting in increased machine cycle times.

We can estimate that, on average, the self-adjusting end-position cushioning system will help users save five minutes from a cylinder's installation and set-u

Self-adjusting cushion (above): Relatively constant deceleration, and thus gentle travel into the end position, resulting from the constant pressure curve.

p time. For a typical application, such as a package sorting system with 60 cylinder-driven routing stations, this would result in savings of five man-hours. Self-adjusting end-position cushioning is a ‛fit and forget' product feature. Since it has no settings to change, it is completely tamper-proof, and it offers a long, maintenance-free service life.

Without any need for manual interventions, self-adjusting cushioning now ensures an optimum cushioning action every time, even if parameters, such as friction and pressure, change. It also reduces the acceleration forces acting on components and work-pieces. This reduces wear and minimizes time-consuming vibration. This unique cushioning, not offered by any other supplier, is now available with the Festo round cylinder DSNU, as well as the compact cylinder ADN, among others.

Customers enjoy the following advantages:

• Time saving (economy) - No need for manual adjustment of the cushioning.

• Accessibility (convenience, economy) - Once cylinders have been installed, carrying out cushion adjustments in a confined area is often a problem.

• Consistent cushioning quality (safety) - Self-adjusting cushioning always deliver the same optimum performance. (There are none of the variations that can occur with PPV when these are adjusted by different people.) Other arguments in favor of self-adjusting air cushioning

• Cannot be varied by machine operator, which means no possible malfunctions.

• Long service life, thanks to optimum cushioning setting, not only for cylinders but for entire installations.

• Optimum cushioning even with varying mass/pressure within permissible range.

Disadvantages: cannot be used when the cylinder is operated at its limits (heavy loads, very high or low speeds).

Find more information about Festo's innovative self-adjusting air cushioning (PPS) at:

http://www.festo.com/cms/en-us_us/14041.htm.

Contact Festo for more information at 800-993-3786.

About the Author(s)

You May Also Like