March 11, 2015

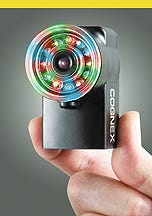

Checker(R) 200 Series next-generation inspection sensor line makes it easy for manufacturers to increase quality and productivity through inspection, according to the co. It adds that the new models are as simple to set up as its Checker 101 line, but are much more capable and are small enough to fit nearly anywhere. Checker 200 is small, smart, simple and powerful enough to solve challenging sensing applications, delivering reliable inspection results, the co. notes. The line is applicable to food, beverage and consumer product package inspection and automotive and electronics part inspection. It offers built-in lighting, a variable working distance and high-speed inspection capability at rates faster than 6,000 parts/min. Checker 200 can also inspect multiple part features and deliver reliable, precisely timed, pass/fail results on even the fastest production lines, according to the co. Unlike conventional photoelectric sensors, the system can detect parts by finding an actual feature, such as a product graphic; checks features such as a code printed on a label; and inspects multiple part features simultaneously, such as candies in a blister-pack.

Cognex Corp.,508/650-3140.

www.cognex.com

You May Also Like