Install-Ready Cobot Palletizer Offers Compact Automation

An off-the-shelf, quick-start, small-footprint system optimizes valuable floor space, increases throughput, and improves flexibility for your end-of-line packaging processes.

Packaging manufacturers seeking to enhance their productivity by adding more machinery are often stymied by their existing floor space, which can be limited.

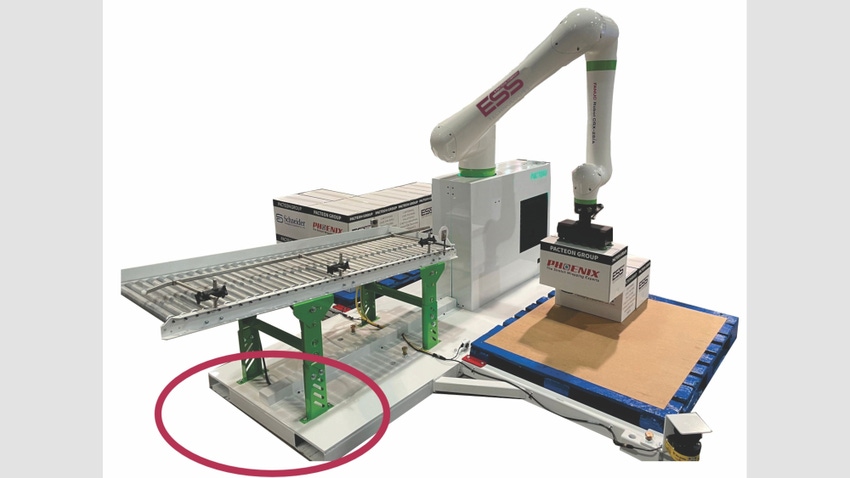

To help businesses expand the use of their existing space, ESS Technologies (Blacksburg, VA) and Schneider Packaging Equipment (Brewerton, NY), both of the Pacteon Group, joined forces to create an install-ready palletizer based on the FANUC CRX-25iA collaborative robot (cobot).

Packaging flexibility and efficiency.

This system is engineered for flexibility, offering a compact cell with one or two pallet positions that accommodate unit load heights up to 60 inches or five feet, meeting the typical pallet height in the US of 48 inches. Floor dimensions for a double-cell system (two pallet positions) is 128.53 inches x 111.81 inches.

It is also equipped with advanced safety sensors so it can operate alongside your employees in a shared workspace without the need for safety fences, further reducing the overall size of the system.

Vacuum-style end effectors efficiently handle one or two cases, depending on your payload and speed requirements. With a reach of 74 inches, the robot delivers high performance while adhering to ANSI/PMMI B155.1 safety standards.

Simple and seamless integration.

The cell operates on 120V, single phase, 15-Amp power and features a skid-ready machine base that simplifies transport and installation. The user-friendly software helps facilitate a quick startup for seamless integration into your production line.

However, what truly makes this collaborative palletizer unique is its ability to adapt to changing production parameters. On-site field service technicians ensure a swift and efficient installation process, commissioning the system in a fraction of the time required by traditional palletizers.

Additional pallet patterns can be quickly programmed onsite, providing unparalleled flexibility to meet your evolving production needs and guaranteeing that the system remains in service for years.

Whether you require a single-cell configuration or dual-cell setup, this collaborative palletizer is versatile enough to handle a variety of products with its maximum payload of 30 pounds, delivering precision and high performance to the forefront of your production line.

About the Author(s)

You May Also Like