Lasers: Package Coding at the Speed of Light

Which of these three laser coding technologies are right for your packaging operation?

November 9, 2023

Ink is not the only option for placing a variable code like an expiration date on your package. Lasers are an excellent alternative. Lasers, as used for package coding, are not printers. Rather, they are “unprinters.” They work by directing an intense beam of light at the label, carton, or bottle and removing ink, coating, or material to form the code.

There are three architectures in use today: Pulse, dot matrix, and steered beam. Each can be recognized by its appearance.

John R. Henry, Changeover.com

Let’s look closer at each type.

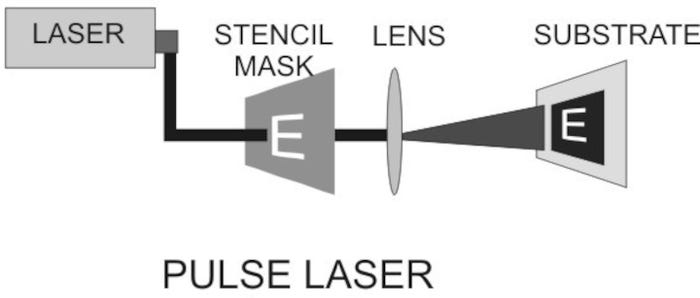

Pulse lasers were introduced in the 1980s. They emit a single intense pulse of light. This is guided by mirrors through a stack of stencil masks and focused by lenses onto the package. They are excellent for high-speed applications (1,000+ products per minute). The downside is that the masks can be cumbersome to manage and change. They also tend to be somewhat bulky.

John R. Henry, Changeover.com

Dot matrix lasers use a series of less intense bursts of light to form the code, similar to inkjet printers. Two architectures are used. One generates a continuous stream of pulses and focuses them onto the package substrate, similar to a continuous inkjet printer. The other uses multiple lasers delivered via fiber optics. These fire as needed to produce the code. They are similar in this way to a drop-on-demand inkjet.

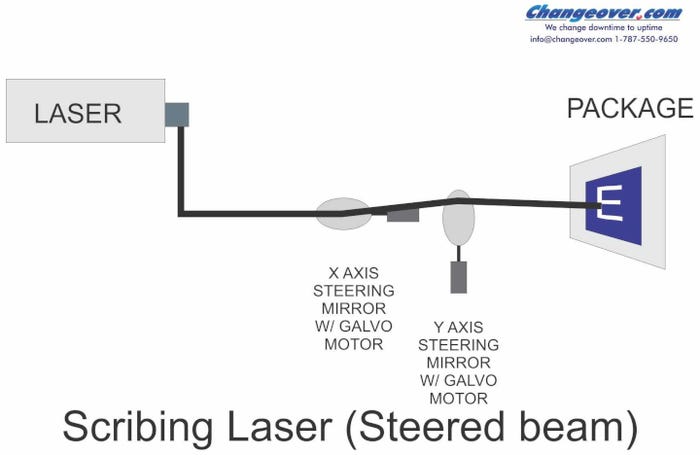

Steered beam lasers emit a continuous stream of small pulses. A pair of mirrors guide the beam in the X and Y axes to draw the code on the product. Although they are discrete pulses, they are slightly overlapped to give the appearance of fully formed characters. This makes for easier readability and better aesthetics.

John R. Henry, Changeover.com

Lasers will not work on all materials. Most packaging lasers will not code on high-density polyethylene (HDPE) because of the wavelength of the laser light and the spacing of the plastic molecules. However, lasers work well on other plastics. Printed substrates require a contrasting color block for best results. Where lasers do work, they are a great solution.

Find out more about Coding and Inline Printing and how it works. It’s all in Chapter 7 of John Henry’s Packaging Machinery Handbook. Other chapters cover inspection, flexible packaging, case packing, and all commonly used packaging machinery. The complete table of contents and chapter samples can be found at www.packmachbook.com/handbooksample.pdf.

Purchase the Handbook on Amazon at https://amzn.to/3kr4qj7.

About the Author(s)

You May Also Like