The Inner Workings of Overflow Fillers

Learn about the three types of overflow fillers for viscous and non-viscous liquids.

April 3, 2024

A previous article explained level vs. volumetric filling. The overflow filler is a common type of level filler. Let’s look at it more closely.

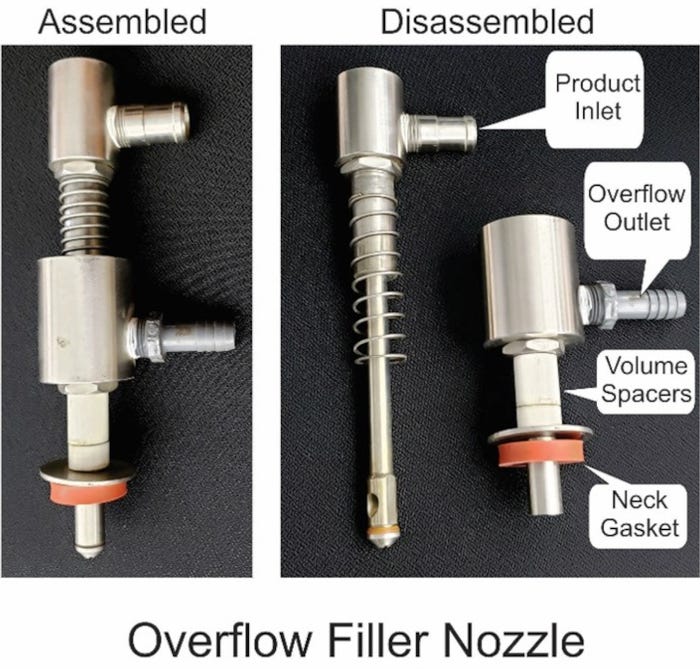

The typical overflow filling nozzle has two ports. One is for the product, the other to vent air and allow overflow product to return to a reservoir.

Frain Industries

The nozzle is pushed into the bottle sealing against the neck and pushing the outer sleeve up. Product flows into the bottle through the center tube, air vents through the outer sleeve. When product reaches the bottom of the vent sleeve, it overflows through the vent to the return tank. Fill level is determined by spacers regulating nozzle penetration depth.

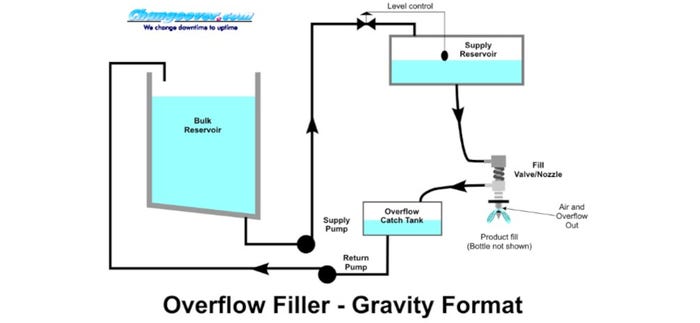

Overflow fillers may use gravity, pressure, or vacuum. The plumbing looks similar but there are important differences. Click through the slideshow to see drawings of each type of system.

A gravity system is the simplest and works well at lower speeds and with non-viscous products.

Pressure fillers add a pump before the nozzle to force the product into the bottle. Pumps can be used to increase throughput or with viscous products, like an oil or shampoo.

Leaks can occur due to a damaged gasket or neck. Vacuum fillers can be useful here especially for hazardous or messy products like nail polish. Any leakage will be air in, rather than product out.

Inline and rotary overflow fillers are both common. Inline fillers are usually intermittent motion and often max out at speeds of 100-150 bottles per minute (bpm). Rotary fillers are usually continuous motion and speeds to 1,000bpm are possible.

It’s easy when you know.

Find out more about filling and how it works. It’s all in Chapter 4 of John Henry’s Packaging Machinery Handbook. Other chapters cover inspection, flexible packaging, coding, and all commonly used packaging machinery.

Purchase the Handbook on Amazon at https://amzn.to/3kr4qj7.

About the Author(s)

You May Also Like