Vodka’s Spirited Change from Glass to Paper Bottles

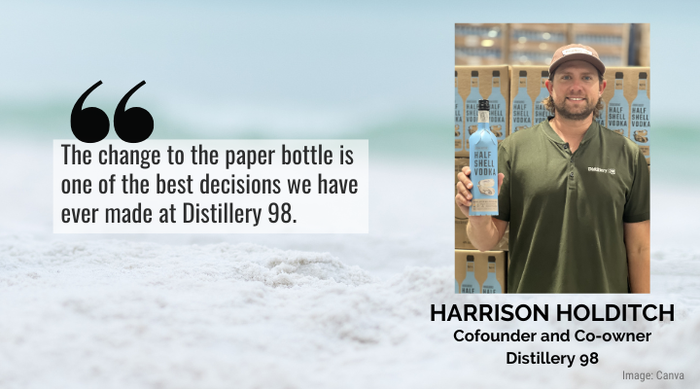

Florida-based Distillery 98’s choice of Frugal paper bottle packaging for sustainably driven Half Shell Vodka echoes a sea change for alcohol brands.

Half Shell Vodka from Distillery 98 reflects the intense passion the micro-distillery’s principals have for sustainability. The brand’s eco story starts with the distillation process that uses only hyper-local ingredients including Florida-grown, self-milled corn, according to cofounder and co-owner Harrison Holditch. Then there’s the oyster shells harvested from the Gulf of Mexico that are a part of its signature filtration not to mention the geothermically cooled water from local aquifers. That keeps the operation’s equipment at a comfortable 50-60 degrees year-round. The company also bottles the vodka on-site.

But it’s the thoughful choice of radically distinctive packaging that’s front-and-center with consumers: The Frugal Bottle paper bottle.

The distillery’s introduction makes it the first US spirits brand in the paper bottle. It’s part of a broader, worldwide wave of bottled adult drinks moving to paper bottle packaging that started with wine.

Holditch shares the brand’s paper bottle story that provides a dramatic “see change” visible on-shelf and drives sustainable benefits that extend from marketing through production and distribution.

It was packaging love at first sight during a chance encounter in London.

“When I first saw and held the bottle, I knew it was the future of Distillery 98,” Holditch recalls. “Hopefully, it’s the future of our industry as well.”

At that point bag-in-box wine had been the only alcohol brand in paper packaging he had known. Holditch instantly appreciated the benefits of the paper bottle.

“Shipping glass and aluminum bottles creates an extensive carbon footprint, so when we found the Frugalpac bottles, it just made sense for our mission as a micro-distillery that strives to be intentional and conscientious with our manufacturing practices,” Holditch says. “We want to minimize any environmental impacts in our local community.”

The distillery is located in Santa Rosa, FL, in the northwest part of state.

“As a beach town on the Florida Panhandle, we wanted to help set an example for other companies,” he points out. “We felt like the bottle aligned with what we're trying to do at Distillery 98.”

According to the Frugalpac and compared to a glass bottle, the paper bottle weighs just 83 grams so is up to five times lighter and has a carbon footprint six times smaller. It’s constructed of 94% recyclable paperboard with an inner food-grade pouch.

Distillery 98 is awash in paper bottle benefits.

“Less shipping weight and costs and eliminating shattered glass bottles are two major benefits that we love,” Holditch says. “We’ve also found that the paperboard allows for a smaller carbon footprint when it comes to manufacturing and recycling.”

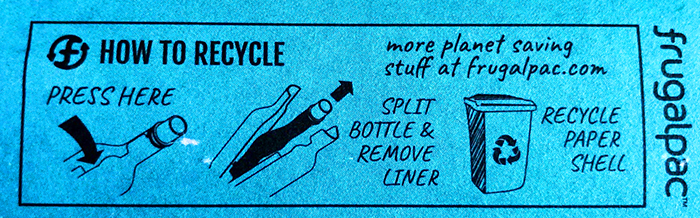

The recycled the packaging, the outer paperboard shell is removed for recycling and a thin, inner plastic pouch that provides a water and oxygen barrier is discarded.

And there’s the paper bottle’s considerable on-shelf impact.

“We believe that the differentiation is everything for Distillery 98 in our Half Shell Vodka brand,” Holditch explains. “We think that having a paperboard bottle and being the first spirit in the US with this packaging presentation gives us a leg up on other vodkas.”

On top of that, the paperboard wrap offers a 360-degree surface for branding, messaging, and more. One of those is the back-of-bottle recycling instructions.

Another is a front-of-bottle.“Ocean Active” callout above the prominent brand name.

“It was our distillery’s way of saying that the unbreakable bottle permits users to be active around the ocean or anywhere glass isn’t allowed,” Holditch explains.

The distillery even leveraged the bottom of the bottle where brand name, logo, and “spirit of the Panhandle” statement are printed.

“That’s far more than typical glass-bottle labels allow,” he points out.

The paper bottle’s impact on production.

The dramatic change in packaging from a heavyweight bottle to lightweight pouch-in-a-paperboard sleeve bottle had as much of an impact on the production operations as on shelf.

“Frugal bottles use a different filling and capping system than traditional glass bottles,” says Holditch. “We brought in two special machines that help us bottle around 400 units an hour at our current capacity. We used a company based in Italy that’s familiar with the Frugal bottle. It was well worth our efforts to go this route.”

|

Several modest modifications were made as well.

“To best handle the paperboard bottle format, we had to add special parts to the capper so the direct pressure wouldn’t crush the bottle,” offers Holditch. “For the filler, we obviously don’t want any spillage on the bottle, so getting a good seal that would properly fill to the desired level was key.”

The changeover to paper bottles also reduced labor requirements.

“The speed and labor efficiency improved dramatically with the new bottling line,” he says. “Because we do everything in-house, this was a game changer for us. With the glass bottles, we would need a minimum of four people on the line, but now we can run the line with a crew of two or three.”

A paper bottle perspective: takeaways and final thoughts.

The whole project opened the micro-distillery’s mindset, according to Holditch.

“We learned that recycling glass bottles creates just as much of a carbon footprint as manufacturing them does. And we figured out that there’s a whole world of sustainable packaging that we’re excited to experience and be part of.

“We also learned that it’s okay to step outside the status quo. We also found that we can trust other companies that align with us to be part of a more sustainable future.”

In the first two-plus months of running the paper bottles, “sales have been good,” Holditch reports. In fact, sales have grown to the point that “we’re already working on upgrading our system to get more off the line,” he adds.

Holditch tells us that feedback has been “great. Everyone is on board with the light, sustainable packaging, especially here along the Gulf Coast.

“To me, the Frugalpac paper bottle is the future in our industry. It works well and we’re very happy with it across our distillery operations and distribution. The change to the paper bottle is one of the best decisions we have ever made at Distillery 98.”

About the Author(s)

You May Also Like