4 ways beverage packagers can boost quality—and ROI

June 14, 2016

With companies running lean and continually seeking further cost efficiencies to be more profitable, one of the first questions asked when deploying a new software system is “how can I obtain return on investment?”

For beverage manufacturers, bottlers and packagers that have implemented or are looking to implement a quality management system, ROI is readily attainable. However, some users are unsure where to look in their quality data for significant returns—many of which are difficult to quantify, but provide long-term value.

Here are four chief areas for generating ROI:

1. Improve yield: Realize ROI by improving yield—that is, by reducing the amount of materials used to create a conforming product that will be sold on store shelves.

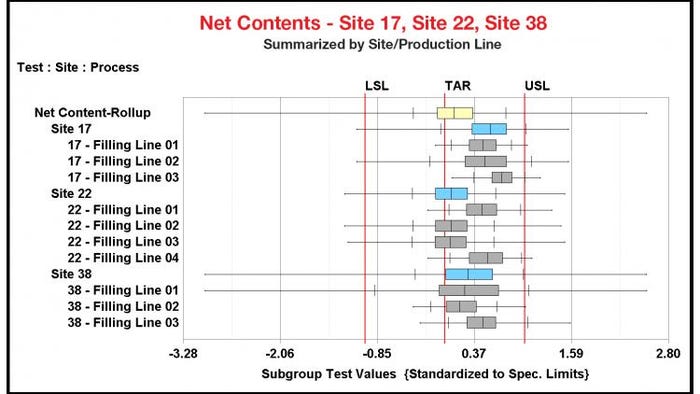

First, look for opportunities to minimize overfill. Consider this scenario: A production line fills more than 90,000 12-oz cans per hour. What if you could determine that each container was three milliliters over target? Further, what if you could eliminate that overfill and still meet net content requirements? Although seemingly small, these savings add up over time, and are even more substantial if these process improvements are repeated across the enterprise.

By observing the average overfill for a production lot and number of units produced within that lot, it is possible to associate a cost with how much product is given away. Then, by looking at the average overfill number and process capability standard deviation, you can re-target and better control your filling processes to reduce costs.

Second, determine if you can decrease syrup or concentrate usage. Indeed, syrup is one of the more expensive ingredients in many sodas and juices. So, naturally, the more syrup used in the mixing process, the more each product costs to make. Therefore, if you can leverage statistical process control (SPC) methodologies to bring the amount of syrup closer to target in each conforming product, you’ll increase the profit margins per bottle and obtain ROI.

With an enterprise quality management solution, beverage packagers can create charts like this box and whisker chart to look at the net content of products from filling lines across multiple sites—insight that helps minimize overfill to generate better return on investment.

2. Mislabeling risk detection: What if an operator incorrectly runs a diet soda in a regular soda can? That mislabeled product will end up as waste/throwaway, or worse—the product could make its way to the store shelf and end up requiring a costly recall. By implementing checks to verify that the correct product is marked with the correct label, you can reduce risks associated with mislabeling, cut waste and minimize brand-damaging recalls to realize both tangible and intangible ROI.

3. Blow molding: Like mislabeled products, defective or non-conforming bottles also end up as scrap or rework. Unfortunately, defective bottles require that production of their associated product must be put on hold until the issue is resolved. This slows down throughput, which translates to fewer bottled products sold. To prevent these costly glitches, look for opportunities to improve the efficiency of your blow molding processes, as well as implement quality checks to optimize use of the bottles you produce.

4. Compliance risk detection: With real-time access to quality data, plants can monitor a variety of information that attributes to the overall quality of the product. This includes the pH of the product, air content and even whether the bottle caps are too tight. While there may not necessarily be a direct cost savings associated with monitoring these quality aspects, you are limiting the risk of market actions/recalls and production delays.

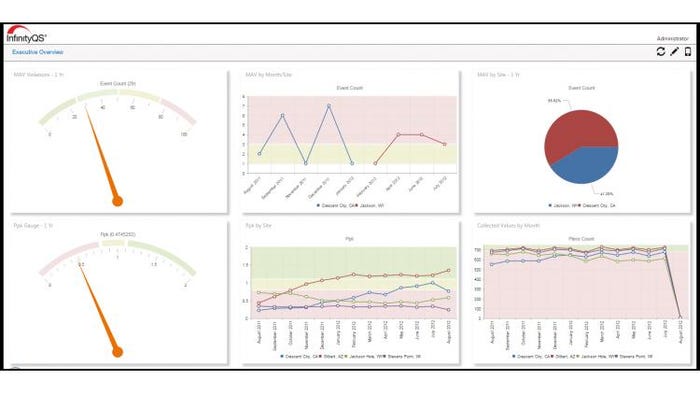

In addition to these four categories, consider the potential savings and new efficiencies not only from monitoring data in real time on the plant floor, but also from aggregating those data to gain visibility into enterprise-wide operations. An enterprise quality management solution allows you to “roll up” data to identify areas for improvement that will positively impact the global organization. For example, you can see what each production line is capable of producing, and then make adjustments based upon which product runs best on which line.

An enterprise quality management system allows beverage packagers to aggregate data from multiple plants for a high-level view of operations to identify areas for global improvement.

Perhaps you can reduce scrap by running more complex products on newer machinery; or, more easily identify and prioritize where to focus continuous improvement efforts and Six Sigma resources. Moreover, a quality system streamlines the analyses of these data by quickly generating reports—saving plants time and money, while helping them meet audit requirements.

Whether your plant is new to an enterprise quality management solution, a long-time user or considering such as system, there are many opportunities to uncover ROI. If you are in early stages of deployment, take the time to set benchmarks so you can more easily track and compare results and progress. Just remember, not all savings are quantifiable. But, if you can prevent risk, create new efficiencies, drive continuous improvements and replicate those efforts across the enterprise, it can make all the difference and allow you to maintain competitiveness and sustainability down the road.

Doug Fair is a seasoned quality professional with nearly 30 years of manufacturing, analytics and statistical application experience. As chief operating officer at InfinityQS, Fair leverages this experience to drive the company’s overall operational performance.

*****************************************************************************************

See a host of new ideas in sustainable packaging at EastPack 2016, June 14-16, in New York City. Register today and use the promo code NY16PD to get free expo admission and 20% off conference passes.

About the Author(s)

You May Also Like