Ball Corp. presents the plastic-replacing aluminum cup

September 3, 2019

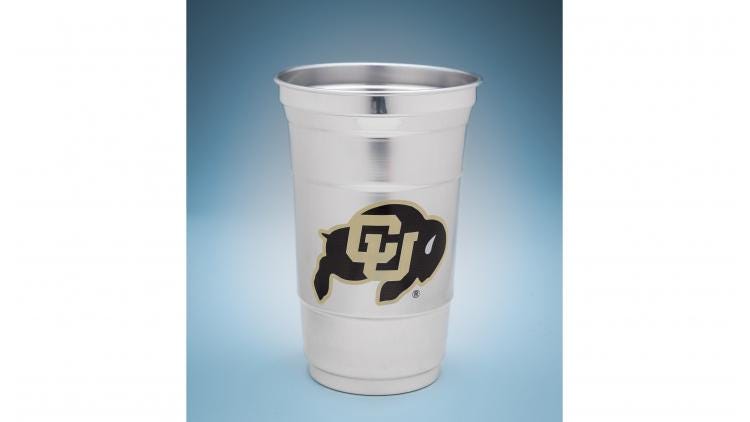

The 20-oz aluminum cup will be tested with major venues and concessionaires across the U.S. starting September 2019 at Colorado University.

The ongoing displeasure with plastic packaging sustainability opens opportunities for alternative materials to supplant polymer-based formats in certain applications.

The next target is the plastic cup: Ball Corp. (Broomfield, CO) announced on August 27 it will roll out a number of pilots with major entertainment venues and concessionaires across the U.S. to replace their plastic drinking cups with 20-oz aluminum cups starting in September 2019 and continuing through 2020.

The metal cup is sturdy, lightweight, durable and cool to the touch, offering consumers an enhanced beverage drinking experience, according to Ball. The vendor’s research shows that 67% of U.S. consumers say they will visit a venue more often if they use aluminum cups instead of plastic cups; 78% expect beverage brands to use environmentally friendly containers in the next five years.

“The aluminum cup is a game-changer for the industry,” Sebastian Siethoff, Ball general manager, tells Packaging Digest. “We hope that our customers and consumers view the aluminum cup as a sustainable and easily recyclable alternative to plastic cups, which are currently a mainstay of stadiums, restaurants and beaches and often end up in the trash or on the ground.”

Those markets are just the start, according to Siethoff. “It is also a great solution for bars or breweries that want a non-breakable substitute for their current barware. In the future, we expect to expand adoption of the aluminum cups at bars, breweries and retail locations.”

And it doesn’t stop there. “We also expect to introduce additional sizes to complete our portfolio in the future based on market demand,” he adds.

CU kicks off first application

On September 3, Ball Corp. announced a partnership to introduce the recyclable aluminum cup to collegiate football fans during the Colorado University home opener at Folsom Field when the Buffalos play the Nebraska Cornhuskers on September 7.

The move will significantly reduce plastic use in the stadium this season, as a major step in the university's goal of becoming plastic-free in its sports venues by 2020. It continues a sustainable tradition at CU that began in 2008, when it became the first major college sports program to implement a zero waste program in all gameday venues.

Earlier this year, CU Athletics became the first university in the nation to sign the United Nations Sports for Climate Action Framework, joining other adopters such as the New York Yankees, NBA and Tokyo 2020 Summer Olympics. The agreement requires entities to reduce climate impact and promote responsible and sustainable consumption.

"Ball and CU have a long history together, and we're proud to team up with them to pioneer sustainable solutions in our industries," states John A. Hayes, Ball's chairman, president and chief executive officer. "With CU's commitment to sustainability, the university is the ideal partner for piloting our new aluminum cup at the collegiate level. Sports fans are becoming more mindful about the impact their everyday choices have on the environment, and we're excited to offer them the opportunity to enjoy their favorite beverage at the game in our infinitely recyclable aluminum cup."

Ball and CU hope that the new aluminum cup will inspire good recycling habits and bring more fans out to games.

A greenfield opportunity

Ball is offering the cups at a flat pilot price to select pilot customers. “True commercial pricing is yet to be confirmed, but we expect it to be competitive with other sustainable cup options,” adds Siethoff.

However, cost savings are not driving the business case for the change: this greenfield opportunity for aluminum packaging is fundamentally a “green”-driven proposition.

“Pilot customers are making a conscious decision to adopt a more sustainable beverage container for their consumers,” explains Siethoff. “Just like aluminum beverage cans, which have a global recycling rate of 69%, aluminum cups are easily recycled while the material retains its value throughout the process. Ball hopes this will lead to high aluminum cup recycling rates from both consumers and customers.”

Ball has not completed a lifecycle assessment of the aluminum cup versus the plastic cup.

“Lifecycle assessment results vary depending on how you run the analysis,” Siethoff points out. “When you consider the entire lifecycle of aluminum and cans’ high recycling rates, aluminum better enables circularity and is more sustainable than plastic.”

The metal cup also presents marketing opportunities that can make an impression with consumers: the aluminum cups can be customized with logos and graphics, Siethoff notes. “We offer customers 360-degree branding, allowing them to create customizable designs for a one-of-a-kind look without compromising on recyclability.”

Although recycling is the cups’ greatest strength, it’s expected that some consumers won’t be doing that, though that’s not such a bad thing. “Given the cups’ lightweight, sturdy nature and eye-catching graphics, we recognize that some consumers may want to keep or reuse it,” says Siethoff.

You May Also Like