Canning olives the Musco way

November 25, 2014

|

After filling, cans of olives are stored "brite" and are labeled when needed. Cans exit the labeling machine sideways and are oriented on a twistrail, shown here, before heading to a tray packer. |

If Musco Family Olive Co. had its way, olives would find themselves on every fingertip in America. Considered the largest U.S. supplier of branded table olives and the leading olive company in the U.S., Musco is known for its Pearls® brand of olives available throughout the U.S. Musco packages many varieties of Pearls in a most progressive facility in Tracy, CA.

Musco reports that a combination of its facilities processes approximately 50 percent of the olive crop grown in the U.S. Musco, which also packs Early California and many private-label olives, manages olive facilities across California. The Tracy plant is noteworthy for being capable of processing more than 50 percent of California's annual olive crop.

Olives are Musco's only business, a fact reflected in its continuing investments in quality materials and packaging equipment to ensure gentle yet efficient handling of the olives.

The Tracy plant cans a full range of black, ripe olives under the Black Pearls brand, including pitted, sliced, chopped and whole ripe olives in several sizes, as well as the Early California brand. The recently introduced Green Pearls green olives and Mediterranean Pearls Mediterranean-style olives, available throughout the East Coast, Upper Midwest and Portland, are grown, packed and labeled in Spain. Jars of Kalamata whole olives originate in Greece.

Tip of a finger

Recently, Musco updated the packaging for Pearls both visually and structurally with design concept, design refinements, line extension designs and a new corporate identity design completed by strategic branding agency Tesser, Inc. (managed by a Musco brother), as well as initial label graphic exploration with Landor Associates. Simultaneously, Musco introduced the Green Pearls and Mediterranean Pearls products. The new packages and label graphics were showcased at Chicago's Food Marketing Institute show for the first time last May (see PD, July '01, p. 44).

The focus of a clever television ad campaign, the top-selling Pearls line now offers consumers greater choices with the addition of the Green Pearls and Mediterranean Pearls product lines. The new labels replace various approaches that evolved over the years. Reflecting Muscos' desire to encourage snacking and entertaining with olives, the redesigned graphics use a rich color scheme of yellow, black, and of course, olive green, to reinforce the Pearls brand as a premier, quality olive.

Can and jar labels illustrate olives bursting forth on a sunny yellow background and the new Musco family logo that presents a childhood-memory-inspired design: a hand displaying five spread fingers, each topped with a black olive, as children like to do. The olive-fingered-hand symbol on a blue background is centered on a black band that features the brand name in white.

The paper wraparound jar labels are printed in five-color process by Etiquetas & Impresos of Seville, Spain. The full-wrap can labels are process-printed in six colors by Fort Dearborn.

Felix Musco, grandson of the company's founder, says the new labels are not only visually appealing, but catch the eye on the containers, which now are made to a uniform height. This makes it easier to merchandise the products.

Easy to stack and ship, the three-piece steel cans for Black Pearls black olives are provided by Crown Cork & Seal and Silgan. The cans in 211/200, 211/304 (smallest), 304/407 buffet (medium) and 300 (for small, medium, large and extra large as well as jumbo and colossal) sizes have drain weights that vary from 2.25 to 90 oz, based on the style of olive packed. Glass jars containing the new Green Pearls and new Mediterranean Pearls stuffed olives, in Jalapeno Stuffed, Garlic Stuffed and Kalamatas, are made to the same height as the #300 cans. The 6- and 10-oz wide-mouth glass jars are produced in Spain by BSN Glasspack Espana, Seville and topped with VEM Group's black-colored closures incorporating a polished-steel litho-printed graphic of the olive-finger motif.

Canning facility

The olive facility runs two eight-hour shifts a day, five days a week. Occupying nearly 350,000 sq ft under one roof, the plant maintains a computerized processing facility with four canning lines, each equipped with predominantly 304 stainless-steel machinery. There are full-can depalletizers from Whallon Machinery, pocket fillers from either Zilli & Bellini (represented in the U.S. by Imdec, Inc.) or Zanichelli Meccanica (Zacmi for short), and can seamers from Angelus, including two new high-speed 62 H systems installed in '00 to close 300-size cans.

Downstream equipment, depending on the line, includes single- and double-stack tray packers from Kisters Kayat, case palletizers from HK and pallet wrappers from Orion and Wulftec.  Allen-Bradley programmable logic controls guide most of the machines on the lines. And, there are numerous quality control and inspection checkpoints throughout the packing operation, says plant manager Dan Ebright. "It seems like a complicated setup, but it's pretty straightforward. We also have USDA inspection onsite, so the product is constantly under scrutiny."

Allen-Bradley programmable logic controls guide most of the machines on the lines. And, there are numerous quality control and inspection checkpoints throughout the packing operation, says plant manager Dan Ebright. "It seems like a complicated setup, but it's pretty straightforward. We also have USDA inspection onsite, so the product is constantly under scrutiny."

|

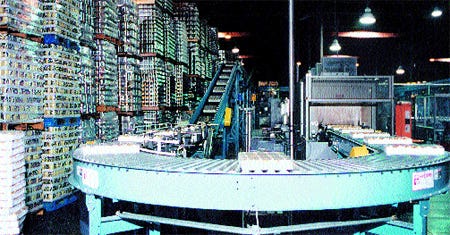

Olives convey in four lanes to a tray packer, above, that can pack cans in single layers or stack them in two layers. Below, shrink-wrapped trays of cans exit a heat tunnel, make a U-turn and incline to a palletizer. |

|

Conveyors supporting the different lines include assorted systems ranging from cable to belt to roller systems furnished by several sources, including Intralox, HK Systems and OHI, which assembled and built assorted conveyor belts, pitter platforms and much of the conveyor framework.

What's best for the olive

Two of the canning lines accommodate 300-size cans, while a third line runs 211-size cans, and a fourth outputs #10 cans. Speeds are proprietary, however.

A unique pumpless, straightline process-flow system uses elevated flumes to transport the olives within the plant to ensure the utmost care in handling. The product comes in contact with only one pump, which is used to transport the olives from the outdoor storage tanks into the facility.

"No one else in the industry that we're aware of uses a pumpless system," Ebright states. "We let the olive design the facility. The plant is structured so that the olives encounter one pump only, and that's when they're released from storage tanks. This is more expensive, but it really affords gently handling."

The imported green olives, already filled in prelabeled jars that are case-packed and shipped to the facility by the palletload, are temporarily stored in the warehouse and/or forwarded directly to customers or forwarding warehouses. The black olives are actually green in color when picked, and then turn black through a processing procedure prior to canning, Ebright tells PD.

|

Shrink-wrapped trays of cans exit a heat tunnel, make a U-turn and incline to a palletizer. |

Before they're canned, the olives are manually checked, are resized for uniformity and are then dropped into flumes. Olives then move in water to feed a series of pitting machines. Then, they're sorted by hand before they reach the canning operation. There, production is divided into separate functions–filling, seaming and retorting are performed on the first leg of the operation–and the olive-filled cans are warehoused and stored by the palletload "brite" before they reach the second leg of the operation–labeling, case-packing and palletizing.

Empty cans arrive on double-high pallets (from 952 to 18,000 cans/pallet, depending on can size) and are unloaded by the sweep arm of an empty-can depalletizer (no longer available), that removes the cans a layer at a time onto a 13-ft-high cable conveyor. The cans then reach blower/cleaners that rotate them 360 degrees before they descend to the fillers.

The rotary pocket fillers capture the empty cans in telescoping pockets underneath the machines. Olives travel in bulk by flumes and then drop through a feed hopper to the filler pockets and into the cans. Musco selected a 36-pocket Zacmi system to fill #10 cans and a Zilli & Bellini 72-pocket filler for the 300-size cans. A Zacmi 56-pocket filler accommodates the 211-size cans.

After filling, the cans single-file to the brining station. Musco modified its briners (some of which were built by OHI in Stockton, CA) to fit the specific needs of its olives. Next, the cans are sent through the Angelus seamers, which use a steam and vacuum process to close the cans. The seamers are also equipped with sensing devices that will shut them down should there be a jam or other problem. The cans then reach one of two Peco Vac-Trac II dud detectors. If anything is wrong, a can will be kicked off-line, and the line may be stopped if necessary, to determine any problems. Then, they're coded with a tracking code by one of four Videojet Excel170i ink-jet coders from Marconi and are elevated by spiral-can elevators from Fleetwood and Millard onto another cable that conveys them to the retorts.

Three straightline, continuous, steam retort systems from FMC cook most of the canned product, but an FMC overpressure automatic batch (ABR) system is used for certain types of olives, Ebright explains. "Actual cook times dictate the machine to which the cans are routed. Some of the products, such as chopped olives, require a longer cooking time, so we needed to have a batch system for them."

|

|

Tray-packs of cans convey overhead onto the infeed of one of two automatic palletizers that unitize them into loads. |

Ebright says that the overpressure system gives Musco flexibility, should packaging structures change in the olive industry.

Cans then phase through the continuous retorts in single-file or are loaded and subsequently unloaded in bulk onto trays into the overpressure ABR and loaded onto pallets by automatic-guided vehicle (AGV). Able to retort 1,050 to 21,216 cans at a time, depending on the can size, the ABR system retorts in just more than 60 minutes, while the continuous retorts operate in less than 30 minutes. The retorts operate at 265 deg F. Cooling follows.

As cans leave the retorts and regroup downstream, they eventually single-file onto a cable conveyor leading to the britestock palletizing area, where they're unitized by one of four Whallon palletizers.

Second phase of packaging

When the cans are ready to ship, the second leg of the operation begins on the other side of the wall. Palletloads of brite cans are pulled out of storage and sent through a labeling/tray-packing/palletizing sequence prior to re-palletizing for shipment. Ebright explains that unlike other fresh products, olives can be packed year-'round. "We pack more product during the winter when the crop is coming in, which meets the needs of the biggest-volume time of year." The amount of cans stored brite in the warehouse varies, depending on the amount of crop produced from the year before, he says. "But we try to maintain a minimum of three to four months' of inventory."

The filled, brite cans are unloaded automatically from pallets by one of three Whallon depalletizers. Staging loads on their infeeds while uploading a third, the machines use a magnetic head to deposit cans onto a conveying bed that singulates them for labeling by either a Mateer-Burt Model 408 Mark 5 or Model 704 roll-through labeler that apply the full-wrap paper labels. They pass the second Peco detection unit and are oriented onto their sides by a twistrail before entering the labeler. After labeling, the cans are inspected by a built-in detection unit.

Cans next are uprighted by another twistrail before eventually single-filing to a Kisters Kayat tray packer that loads them into trays or on corrugated pads in counts of six, 12 or 24. Kisters Kayat TP50 and TP60 machines, both equipped with 801 shrink tunnels, handle the majority of packages. The larger #10 cans are usually case-packed in full corrugated shippers by a case packer no longer available. Gaylord Container provides the shippers.

The cans may be grouped in various formations as lugged side chains merge them into such configurations as 6x4 in the case of a 24-pack. Finished trays, pads or cases of cans are then ink-jet-coded by a Domino Solo or Codebox case coder and are then shrink-wrapped inline on Kisters Kayat combination wrapper/shrink tunnel machines. The completed packs then feed to one of two palletizers from HK Systems. Loads can contain as many as 2,226 cans. Musco can provide customers with display-ready modules of the different products, in which the cases of jars and cans can be inter-mixed when palletized and made into end-aisle merchandisers at stores.

Filled pallets are stretch-wrapped on either the WORT-200 from Wulftec or the MA-66 from Orion. The loads are identified by a license plate/bar-coded label printed using Highjump software and applied by hand. They're then warehoused three and four loads high.

"The flexiblity we've built into our operation will effectively take us into the future," Ebright says. To that effect, the plant may begin updating its empty can handling and storage capabilities. With such a progressive operation that's continuously growing and improving, Musco indeed will put an olive on the tip of many a finger.

More information is available:

Graphics: Tesser, Inc., 800/310-4400. Circle No. 201.

Graphics: Landor Associates, 212/614-4044. Circle No. 202.

Cans: Crown Cork & Seal Co., Inc., 215/698-5100. Circle No. 203.

Cans: Silgan Containers Corp., 818/ 348-3700. Circle No. 204.

Jars: BSN Glasspack Espana, 34 95 445 66 99. Circle No. 205.

Jar labels: Etiquetas & Impresos, 34 95 468 0762. Circle No. 206.

Closures: VEM Group, 34 93 363 2500. Circle No. 207.

Can labels: Fort Dearborn Lithograph Co., 773/774-4321. Circle No. 208.

Z&B fillers: Imdec, Inc., 530/661-9091. Circle No. 209.

Filling: Zanichelli meccanica (Zacmi USA), 408/433-0100. Circle No. 210.

Seaming: Angelus Sanitary Can Machine Co., 323/583-2171. Circle No. 211.

Retorting: FMC FoodTech, 312/861-6000. Circle No. 212.

Conveying, cable transport, brining: OHI Co., 209/466-8921. Circle No. 213.

Conveying: Intralox, Inc., 800/5354-8848. Circle No. 214.

Coding: Marconi Data Systems, Inc., 800/654-4663. Circle No. 215.

Coding: Domino Amjet, Inc., 800/444-4512. Circle No. 216.

Elevating: Fleetwood, Inc., a Barry-Wehmiller co., 630/759-6800. Circle No. 217.

Elevating: Millard Mfg. Corp., 402/331-8010. Circle No. 218.

Labeling: Mateer-Burt, 610/321-1100. Circle No. 219.

Dud detection: Peco Controls Corp., 800-732-6285. Circle No. 220.

Case packing, shrink wrapping: Kisters Kayat, 386/424-0101. Circle No. 221.

Trays, cases, pads: Gaylord Container Corp., 847-405-5500. Circle No. 222.

Case palletizing, conveying: HK Systems, 606/334-3027. Circle No. 223.

License plate labeling software, printing: Highjump Software, 952/947-4088. Circle No. 224.

Pallet wrapping: Wulftec Intl., 819/838-4232. Circle No. 225.

Pallet wrapping: Orion Packaging Systems, Inc., 901/888-4170. Circle No. 226.

Palletizing, depalletizing: Whallon Machinery, Inc., 219/643-9561. Circle No. 227.

PLCs: Allen-Bradley Co., 440/646-5000.

About the Author(s)

You May Also Like