Crystal Geyser Bottled Water Adds Second In-House rPET Plant

Tennessee plant supports brand owner CG Roxane’s goal of blowmolding water bottles nationwide with at least 50% rPET content.

CG Roxane, the Novato, CA-based producer of Crystal Geyser Alpine Spring Water, has opened its second in-house recycled PET (rPET) plant. The new facility, in Benton, TN, supports CG Roxane’s goal of producing water bottles with at least 50% rPET content.

The company’s original in-house rPET plant is in San Bernardino, CA. Together, the two facilities will supply CG Roxane’s bottlers nationwide with rPET pellets to create new bottles.

By using half (or more) rPET in its bottles, the company estimates it will save nearly 33,000 metric tons/36,376 US tons of carbon dioxide per year.

To create the Benton rPET plant, CG Roxane retrofitted an existing building on the site of its Benton bottling plant as a 40,000-sq ft storage warehouse for raw materials and finished product.

For the rPET operation, the company erected a new 20,000-sq ft building with higher ceilings, thicker floors, and space for the production line, plus office space, lab, and maintenance areas. The two buildings are connected by a tunnel so forklifts can move product between them.

Benton rPET operation mirrors San Bernardino, but with new technology.

“We use a mechanical process to generate our rPET production. The [Benton] facility is fitted with an Erema Vacunite line capable of producing 1,650 kg [3,638 lb] of rPET resin per hour. The new facility also contains all auxiliary equipment necessary to support it,” Luke Genthe, special projects engineer at CG Roxane, tells us.

He adds, “The Benton plant was built as a mirror of the San Bernardino plant, with almost the same machinery and resultant output. While the Benton plant was outfitted and set up based on San Bernardino, the technology has improved significantly since we opened San Bernardino.”

Opened in 2019, the California plant made CG Roxane the first bottled water company in the US to open its own recycled PET facility.

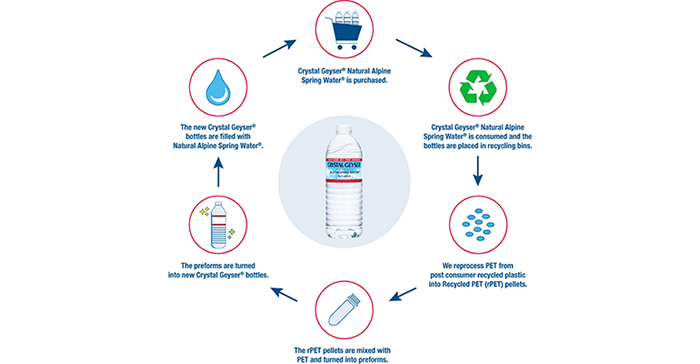

At both its rPET plants, the company accepts sorted, cut, cleaned, and recycled PET flakes from recycling partners. It then processes the rPET flakes into pellets, conducting purity checks on each batch, and ships the pellets to its bottling plants. There, the rPET is made into new bottles via injection blow molding.

“Our bottling and rPET plants work in tandem,” Genthe explains. “All rPET pellets are mixed with virgin PET in-house and turned into preforms that become Crystal Geyser Alpine Spring Water bottles made with a minimum of 50% rPET content.”

The company’s goal is for the Benton and San Bernardino plants to jointly process 39.2 million pounds of PET flakes into recycled PET in 2023 — roughly the equivalent of 1.7 billion water bottles.

A broader sustainability push.

As part of its overall sustainability strategy, CG Roxane also addresses transportation-related greenhouse gas emissions and in-plant energy consumption.

“All Crystal Geyser Alpine Spring Water bottles are manufactured in-house across seven plants nationwide and filled with natural alpine spring water at a nearby spring source,” Genthe says.

“As is the thinking with distance between our spring-water sources and bottling plants, we have situated our rPET facilities at an optimal proximity from both, to limit carbon emissions through transporting materials and shipping,” he adds.

In addition, CG Roxane installed SolarEdge Smart Panels at its San Bernardino plant in 2022 to reduce use of energy derived from fossil fuels. The solar panels provide 30% of the plant’s power needs, on average.

The company is doing its part to educate consumers about their role in recycling, as well. Its new media campaign explains to the public the process of turning post-consumer bottles into new rPET water bottles.

Results of a consumer survey commissioned by CG Roxane underscore the need for such education. The May 2023 survey of 2,000 US adults revealed that:

Only 34% of respondents said they do their part vis-à-vis recycling.

32% could not correctly identify the universal recycling symbol. Asked the meaning of the numbers inside the triangle, only 35% knew that they identify the plastic type.

51% were unaware of corporate post-consumer recycled (PCR) plastic initiatives. After learning what PCR means, 56% of respondents said buying PCR plastic products would be important to them.

At the same time, 34% of respondents said they take recycling very seriously and 32% are proud of their recycling efforts.

About the Author(s)

You May Also Like