Farmers Dairy's form/fill/seal system creates new landscape

January 29, 2014

Consumer convenience is something that transcends borders. In Nova Scotia, Canada, Farmers Dairy offers consumers a new carton design that includes a plastic screw-cap system for

its paper-based milk cartons. The new closure system offers reclosability for the company's milk product line and the Looney Tunes™ flavored milk line. The different milk product lines offer sizes ranging from 250 mL to 1 L.

Previously, Farmers Dairy had been using gabletop cartons. However, it saw a changing dairy market in Canada and decided it was time say good-bye to gabletop. Andrea Hickey, marketing and communications manager, Farmers Dairy, says, "The landscape has changed dramatically for milk packaging in Canada. With the new Tetra containers, we now have a reclosable, attractive package, and we receive a longer shelf life with the Tetra Top package."

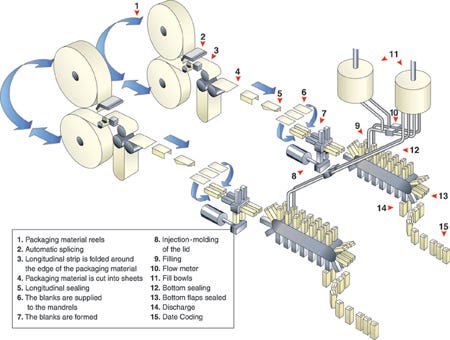

Helping achieve this departure from gabletop packaging has been the North American debut of the Tetra Top package and the system that produces it, the TT3 horizontal form/fill/seal system from Tetra Pak. The system consists of dual lanes that jettison product output levels to 9,000/hr and offers two product tanks–filling bowls–located on the top of the self-enclosed packaging system. With a dual-line design, the f/f/s system can run two separate products and two different sized packages at the same time. At Farmers, they run Base and Midi sized packages on the two separate lines. The Base line is set for larger sizes, such as 1-L and 500-mL cartons, while the Midi line fills 250-, 375- and 500-mL single-serve cartons. During PD's visit to Farmers, the Base line was running the 1-L size of Farmers' 2-percent and homogenized milk.

A 'milky' history

Farmers Dairy has a long history in the Nova Scotia area. The company has been in business for 80 years, under different names through those years. Since 1961, it has been Farmers Dairy and is a cooperative of 200 dairy farmers from Nova Scotia and Newfoundland. Farmers offers 2-percent, 2-percent partly skimmed, homogenized and 1-percent white milk, along with chocolate milk, cream and whipping cream in the new plastic-endcap cartons.

Besides Farmers' milk products, the company signed an exclusive agreement with Bravo Foods in 2002 for Canadian distribution of the Looney Tunes flavored-milk product line. The milk flavors include banana, strawberry, orange cream, chocolate and vanilla, and are packaged on the TT3 machine also. The Looney Tunes' line uses the 375-mL single-serve container exclusively and features the low-density polyethylene screw-cap.

The Looney Tunes line and the Farmers brand are distributed completely refrigerated and are stored in refrigerated retail cases for stores such as Sobey's, Atlantic Wholesale Superstore, convenience stores and foodservice channels across Canada. Farmers distributes its milk products to all of Canada's provinces, except for New Brunswick.

Launching pad

In May, 2002, Farmers installed the servo-driven TT3 system at its approximately 180,000-sq-ft packaging plant in Bedford and, in the process, became the first North American operation to feature this f/f/s machine. One compelling feature of the system is the injection-molding application, called the lid-forming unit. The LFU creates a PE endcap that also includes a threaded spout where the screw cap is affixed. Kim Hamilton, director of technical services, Farmers Dairy, says, "The packaging system offers a friendly design from an operators' standpoint, and the closure-producing system is impressive. With a screw cap, the package offers us an opportunity to be a leader in the dairy industry in Canada."

The f/f/s system begins with an 11-in. preprinted rollstock web that is loaded onto material reels. The coated rollstock runs bottom-side-up continuously through the f/f/s machine by servo-driven piston pushers. Tetra Pak gravure-prints the rollstock, using four to five colors for each milk product carton at Farmers. The rollstock is comprised of three layers: PE, paper and PE. Tetra Pak supplies the rollstock, and the material's thickness is proprietary.

and PE. Tetra Pak supplies the rollstock, and the material's thickness is proprietary.

The rollstock travels vertically through five traversing rollers and moves to a station where a longitudinal strip is folded around one edge of the rollstock. Once the strip has been applied, the rollstock passes by a photoeye that identifies registration marks, located on the leading edge of the rollstock. The photoeye signals a vertical cutoff knife and cuts the rollstock material into individual, 103/8 x 10-in. blanks.

The dual-lane f/f/s system uses two servo motors to cut the rollstock into individual blanks, one dedicated for each line. Farmers utilizes brushless GS30 servo motors from Exlar Corp. Six servo motors are used for the entire packaging system–two for cutting rollstock blanks and four for filling functions. A GE Fanuc Series 90-30 programmable logic controller with VersaPro software provides control for the entire f/f/s system, discharge conveyors and capping machine. Farmers also uses six DMC servo drives from Atlas Copco.

Once the rollstock material is cut into individual blanks, an overhead plastic belt with guides moves the flat carton blanks into a single-file configuration towards the longitudinal sealer. Conveyor guides fold the flat carton blanks and allow the two edges to be aligned for sealing. Heat is applied to the longitudinal seam, and a contact seal is created. The carton blank is then transferred in flat form to a staging area, where two carton blanks wait for transfer.

There, two rotating arms transfer the flat carton blanks, by suction cups, from the staging area down one level to the mandrel-positioning station. During this process, the suction cups partially open the flat carton blanks. Directly opposite of the positioning station are two male-forming mandrels, emanating from a central hub that rotates in a counter-clockwise fashion. The two, preopened carton blanks are moved by a sliding cam onto the mandrels and then are transferred to the lid-forming unit.

In-line injection molding

At the LFU, a specified amount of PE resin is released by an outer tool at exactly the same time as the carton blanks arrive on the male mandrel. A heated spring metal tool located on the forming mandrel meets the outer tool on the LFU and creates a plastic lid. The tools use heat and pressure to create a "welded" action and seal it to the carton. The plastic lid includes a spout with an inner safety-resistance seal that also allows for bottom-up filling. During lid forming, the inverted carton's top remains untouched and in tube form. "The lid-forming unit marries a plastic endcap to a carton bottle within a matter of a couple seconds," Hamilton says. (For a complete description of the lid-forming unit, see the sidebar below). With the lid-forming unit, Farmers was able to achieve a longer shelf life with the plastic endcaps versus the gabletop packaging, PD is told.

|

A sliding cam transfers two carton blanks onto male forming mandrels. From there, the mandrels move in a counter-clockwise direction to the lid-forming unit. |

With an endcap affixed to the cartons' bottoms, two cartons slide off the mandrels onto vertical, stainless-steel product cassettes. The product cassettes travel on an oval conveyor track inside the filling and sealing area. The cassettes hold the inverted containers throughout the filling and sealing areas, and release them at the discharge area. Cartons are sterilized in the filling and sealing area, which is an enclosed chamber, by a standard HEPA sterile air system. The sterile air flows from the top of the chamber, through the filling head area and then throughout the chamber. This action, along with the enclosed area, ensures that cartons do not come in contact with external air.

Also a hydrogen-peroxide mist is sprayed into the container, and an ultraviolet light is flashed into the carton before it's filled. "From a manufacturing perspective, the system has a high level of quality-control measures and assures us that the milk product will be maintained in the package," Hamilton says.

At the filling area, the bottom-up carton and the cassette are pushed upward into the filling heads. The bottom-fill system uses two filling bowls, or product tanks, to draw upon and fill the different lines. The flexibility of this dual-lane system and the two filling bowls allows Farmers to run one product on both filling lines, or run only one lane, PD is told. Currently, Farmers is averaging production rates of 4,500 containers/hr for each filling line and processes more than 60 million L of milk/yr.

After being filled, the bottom-up cartons are immediately sealed using ultrasonic heat, and then the bottoms are folded by overhead guides. The guides perform a triangle fold, and the flaps are then glued to the flat base. From there, the two product cassettes hold the newly formed, inverted cartons as it follows the oval track. At the discharge area, the track rotates underneath the filling area, and the product becomes upright. At this point, the product cassettes release the cartons to the discharge conveyor line.

Farmers averages five to seven product changeovers per shift, for both the Midi and Base lines. The changeovers are completely tooless and are done from the touchscreen controller. Farmers' production schedule varies, with two to three shifts per day comprised of eight to 10 hours each.

Reclosable cartons

In a single-file formation on the discharge conveyor, the cartons move to a Domino C6000 ink-jet coder. The coder applies a best-before date to the carton's lid and then travels to a Tetra Trepak in-line capping machine. Electric belts in the capping machine apply the 38-mm LDPE screw caps, supplied by Tetra Pak. From there, Tetra Pak variable-speed outfeed conveyors turn left and eventually loop back toward the bottle-capping area. Next to the bottle-capping machine is the case-packing system. Cartons move to an accumulating and sorting area, before being packed by the Tetra Cardboard Packer 70 overwrap case-packer, supplied by Tetra Pak.

|

The bottom-up carton and cassette are moved upward to the filling heads. |

There, flat corrugated cases are transferred by suction cups into the forming area. The case packer organizes the cartons into rows of four and slides the cartons to the case-forming station, in a 3 x 4-carton setup. Forming guides wrap the corrugated case panels around the product setup, and top flaps are glue-sealed using adhesive applicators from Nordson Corp. The 500-base, scored corrugated cases are supplied by Maritime Paper Products. The case packer is the only non-servo-controlled machine on the packaging line. Filled cases are then moved to a Domino C6000 ink-jet coder via conveyor, where the Farmers logo, date, time, quantity and product description are applied to the case. After coding, the cases move to a separate distribution area and are hand-palletized.

With market changes in Canada, Farmers saw the opportunity to capitalize on a consumer trend and needed a f/f/s system to facilitate that move. Hamilton says, "We felt the screw-cap and lid forming unit addition allowed us to go forward as a leader in the dairy industry."

|

The bottom-up cartons are sealed by two steel blocks using ultrasonic heating. Then, overhead guides perform a triangle fold on the carton bottoms. |

Farmers Dairy developed a relationship with Tetra Pak during a previous installation at the Bedford plant. "For the TT3 installation, Tetra Pak sent support personnel to help us integrate the whole system, including the conveyors and case packers," Hamilton says.

Regarding the ROI, Hamilton says, "We've have had success with the Looney Tunes products and the ROI has fallen in line for year one, but we're looking for a greater return as more distribution outlets come aboard."

More information is available:

Hf/f/s, rollstock, in-line extruder, capper, conveyors, case packer: Tetra Pak, Inc., 847/955-6000. www.tetrapak.com. Circle No. 252.

Servo motors: Exlar Corp.,952/368-3434. www.exlar.com. Circle No. 253.

PLC, VersaPro software: GE-Fanuc Automation, 800/432-7521. www.gefanuc.com. Circle No. 254.

Distributor: Atlas Copco, 800/582-6726, www.atlascopco.com. Circle No. 255.

Ink-jet coder: Domino Amjet, Inc., 800/444-4512. www.domino-printing.com. Circle No. 256.

Glue applicators: Nordson Corp., 800/683-2314. www.nordson.com/packaging. Circle No. 257.

Corrugated cases: Maritime Paper Products, 800/565-5353. www.maritimepaper.com. Circle No. 258.

Lid-forming unit |

An in-line injection molder for a form/fill/seal system? Tetra Pak's TT3 machine offers a lid-forming unit that produces injected-molded lids for immediate application to various sized cartons. Here's how it works at Farmers Dairy in Nova Scotia, Canada: |

A 'Classic' history |

In 1952, Tetra Pak delivered its first Tetra Classic system to the Lund Dairy Association in Europe, which eventually produced tetrahedron-shaped cartons. In 2002, Tetra Pak celebrated the Tetra Classic system and the company's 50th anniversary as a leading liquid processing and packaging company. Although the company was founded in 1950, it decided to coincide the anniversary with the delivery of its first machine. |

About the Author(s)

You May Also Like