3 ways to ensure your pharma filler is operating efficiently

August 8, 2016

Inefficiency in liquid-filling operations for pharmaceutical products can result in a significant reduction of productivity and profitability. Thankfully, there are ways companies can avoid issues of inefficiency and keep their production lines consistently effective.

1. Perform Regular Preventative Maintenance on Liquid Filling Machines

Like many other types of packaging machines, liquid fillers wear down over time. Certain parts will eventually require replacement to keep the machinery functioning optimally, and the best way to make sure all of your parts are in working condition is to perform preventative maintenance checks at regular intervals.

Sometimes it isn't easy to detect any inefficiency, but closely inspecting liquid filling equipment can help production line managers and employees detect potentially problematic parts and address any issues before they worsen. Taking these steps can also help you avoid costly breakdowns and downtime that occur when machinery fails, allowing your facility to remain at its most productive.

Next: Training

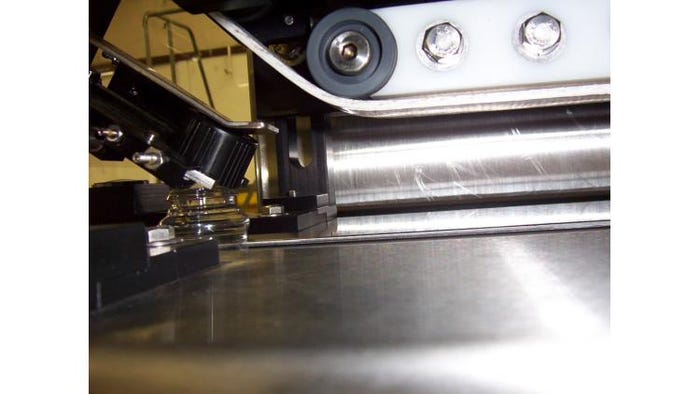

Above: E-PAK Machinery Capping Machine for Pharmaceuticals

2. Provide Proper Training for Operators

Sufficiently trained employees are as vital as fully functioning equipment. Companies may provide basic training for operators when hiring them, but as machinery is replaced and programming changes, operators may not fully understand how to handle new equipment. Production line managers should not only provide extensive introductory training, but they should also provide training when new equipment comes in to help make sure they're familiar with it prior to operation.

While operators might be familiar with one piece of equipment, they may be unsure about how to operate equipment with updated mechanics and programs. Certain companies that sell liquid-filling equipment will also offer operator training services to help accustom employees to newly installed machines, preparing them for when the equipment starts working.

With operators on your team who know exactly how to operate all of the equipment utilized in your facility, you can benefit from maximized productivity and subsequently more profitability.

Next: Improve performance

3. Implement a Performance Improvement Plan

Another highly effective way to increase efficiency is to come up with a performance improvement plan that measures your facility's output and gives you ideas about how to further improve it. Through performance improvement, you can develop procedures that help guarantee maximum profitability.

Using a performance improvement plan, you can pinpoint areas of inefficiency among the workforce and determine whether more training is necessary or whether a new piece of machinery is ideal for implementation in your liquid filling and other packaging systems.

By ensuring your equipment and employees are performing the way they should, with procedures in place that are helping maintain adequate efficiency in your facility, you'll be able to benefit from a production line that gives you the best achievable results.

Keep Your Facility Efficient with Productive Equipment and Staff

With the help of preventative maintenance checks, operator training, and overall performance improvement, pharmaceutical companies can prevent their liquid-filling lines from becoming dangerously inefficient. You'll be able to identify potential issues before they become immensely problematic, determining the steps you need to take to improve employee efficiency or improve your equipment.

To keep machines from breaking down, preventative maintenance is invaluable. Operator training will make sure that your employees continue to help give you the results you want, with all of the knowledge and expertise necessary to properly handle all equipment. With a performance improvement plan integrated into your operations, you can further determine which areas of your production line could benefit from additional attention. Combining all three of these crucial elements will enable you to stay on top of your facility's operations, with minimal issues regarding inefficiency of production.

Krys Beal oversees the inside sales and marketing department at E-PAK Machinery Inc., a manufacturer of in-line liquid packaging machinery.

***********************************

Looking for inspiration for your next packaging project? Visit MD&M Minneapolis and MinnPack September 21-22 for the latest in packaging materials, equipment, automation, and more!

About the Author(s)

You May Also Like