Graphene Makes PE Stretch Film Ultrathin and Strong

Film manufacturer Packseven is rolling out a recyclable polyethylene stretch film made with Gerdau’s graphene masterbatch that reduces virgin resin use by 15% to 30%.

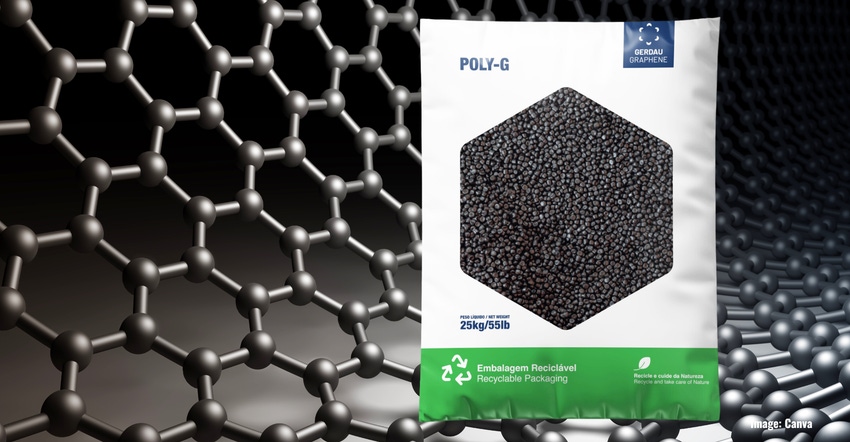

Graphene technology is to thank for the commercialization of a new type of stretch film that is significantly thinner and more durable than conventional alternatives. The new graphene-enhanced stretch film, from film manufacturer Packseven, incorporates the Poly-G graphene masterbatch from Gerdau Graphene.

The companies, both based in Brazil, claim Packseven’s new product is the world’s first commercial stretch film enhanced with graphene, an exceptionally strong material featuring an atomic monolayer of carbon atoms arranged hexagonally in a honeycomb-like structure.

When blended with plastics, graphene lends its strength to the polymer matrix and greatly strengthens the blended plastic. Graphene improves physical and mechanical properties like puncture-resistance and increases barrier properties against liquids and gasses. It also protects against weather, oxidation, and ultraviolet light, and boosts electrical and thermal conductivity.

Packseven’s graphene-enhanced stretch film is expected to be available for sale in the third quarter of 2023, launching in Brazil.

Additionally, “The Poly-G masterbatch used to create Packseven’s product is currently available in Brazil and Japan. In Japan, Gerdau Graphene has a strong partnership with Sumitomo to commercialize the product,” Alex Correa, CEO of Gerdau Graphene, tells us.

Poly-G can be exported to US plastics manufacturers, he adds.

Advantages of graphene masterbatch enhancement.

Incorporating graphene into plastic films offers plastics companies and their customers transportation, storage, and packaging benefits vs. conventional films.

Initial testing of Packseven’s ultra-thin stretch film shows that the film can pack 120% more material without breaking, vs. other stretch films. Graphene-enhanced stretch films are more resistant to being punctured by sharp objects, as well.

The graphene-enhanced film’s durability translates into reduced consumption of stretch film per pallet and safer packing and loading. Its improved strength and durability also make it possible to significantly reduce the thickness of the film.

Thus virgin plastic use is reduced, resulting in a higher-performance, more sustainable low-weight film. Furthermore, the virgin resin reduction drives down post-consumer polyethylene waste.

The enhanced film is recyclable, too. “The recyclability of the final polymer product is unaffected by the addition of graphene to the polymer mix,” Correa says.

Graphene masterbatch’s ROI cost benefits.

Gerdau piloted the Poly-G masterbatch in a series of industrial applications in its own factories prior to commercializing the additive. In one pilot, a graphene-enhanced film for construction-nail packaging was tested.

“Gerdau found that by using the new, 25% thinner graphene-enhanced plastic film, far fewer nails perforated the packaging. As a result, Gerdau reported a 39% reduction in the volume of discarded damaged packaging and a 7% increase in film productivity,” Correa reports.

As for the cost of the Poly-G masterbatch, Correa says it “may have a higher initial price when compared with traditional performance masterbatches, [but] the ROI cost benefit is clear.”

Specifically, the additive enables plastics manufacturers to reduce their use of virgin resin by 15% to 30%. They also experience improved thermostability in production, which can produce 5% to 8% higher throughput and may result in manufacturing cost savings. Plus, they can offer a higher-performing product at a more competitive price.

About the Author(s)

You May Also Like