How Your Flexible Packaging Operation Can Be More Productive

Make the most of a flexible packaging strategy that supports production efficiency, variety, and sustainability.

Packaging companies are required to do more with fewer resources — in addition to offering greater product variety and demonstrating environmental sustainability to an increasingly discriminating consumer base. Fortunately, flexible packaging can help companies meet sustainability demands without incurring significant productivity losses.

By using less material per package and expanding the options for colorful and creative visual presentations, this strategy promotes environmental health and helps different products stand out on retailer shelves.

There are still some challenges, however. The changeover process for flexible packaging — if not done properly, and without the right equipment — can be a sinkhole for productivity.

When machinery is overly complex or operators lack the right training, changeovers take longer, making it less lucrative to offer a variety of products. Packagers also need to ensure the reliability of their equipment while washing it down with harsh chemicals and high-pressure water jets.

As we explore several current trends in flexible packaging, here are five ways to mitigate its production challenges.

1. Ensuring seal integrity.

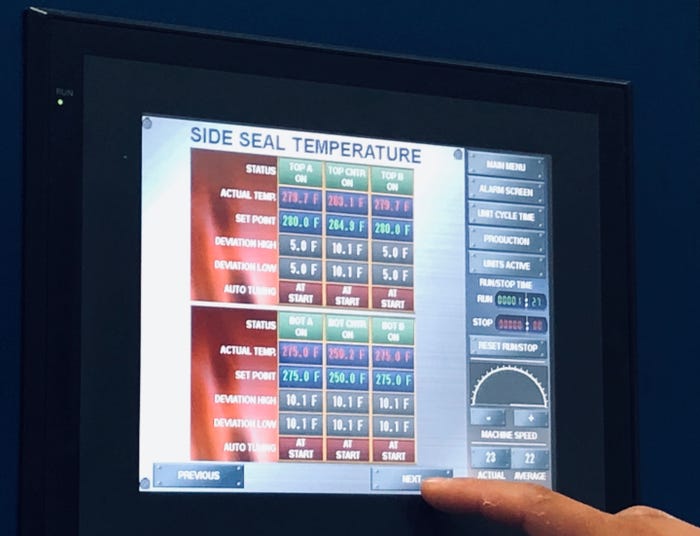

A common goal of food and beverage manufacturers is to find ways to extend the shelf life of their products. One of the best ways to do this is to make sure the packaging film is properly sealed every time. Sensors can detect seal integrity, while temperature controllers can ensure that heat levels do not get too high to burn through films during sealing. This is especially critical for manufacturers seeking to reduce their plastic footprint by making films thinner, since the sealing bar is more likely to accidentally burn through the thinnest of films.

Servo motors also play an important role in ensuring seal integrity. Since servos are responsible for moving product along the production line, they can control the speed at which the sealing process takes place. By positioning the plastic in just the right spot and preventing it from lingering too long, servos help ensure an accurate cut and a proper seal. Manufacturers noticing frequent sealing problems can usually solve the issue by upgrading the temperature controller, the servo system, or both.

2. Switching between different films.

Supporting a range of stock-keeping units (SKUs) — while also taking advantage of the latest packaging-related efforts to promote sustainability — requires the ability to easily switch between different types of films. Modular technologies, such as collaborative robots, can make these changeovers much easier thanks to their flexibility in accommodating new tasks and their ability to work safely alongside a human operator.

Modular technologies are easier to scale up or down depending on demand. Production lines are also more flexible when they have a smaller footprint. Many technologies, from smart cameras to predictive maintenance devices, free up more space for switching up the layout or adding new functionality when the need arises.

3. Making machines easier to use.

If changeovers are going to occur with greater frequency, then operators need machines to be easily accessible and user-friendly. Complex machinery will only serve to draw out the changeover process.

These challenges can be improved with more training for the operator, especially in video form, so manufacturers should be sure to check out an automation supplier’s training offering before making a selection. It also helps if the supplier can provide condensed manuals in addition to the more comprehensive ones.

Human-machine interface (HMI) technology with better visuals can make a huge difference in an operator’s ability to use new equipment or use the same equipment in new ways.

4. Making machine easier to clean.

Keeping things clean is one of the biggest challenges in food and beverage manufacturing plants. Frequent wash downs are essential for maintaining hygiene, but the harsh chemicals, high pressures, and extreme temperatures involved can also damage the delicate interiors of sensors and other devices, cause them to break down earlier than expected.

Fortunately, automation partners offer product lines designed specifically for manufacturers that perform washdowns regularly. IP69K-rated products are recommended for the most extreme washdown environments, as these can withstand high-pressure water jets. Washdown-rated products include sensors, pick-and-place robots, emergency stop pushbutton switches, and much more. For light washdowns, IP67-rated products are often suitable.

5. Improving equipment reliability.

To better deal with the added complexity that flexible packaging entails, manufacturers need to have confidence that their equipment will function reliably. Some machinery makes it difficult for maintenance personnel to access key areas, so machine builders need to incorporate ease of access into their designs without sacrificing safety.

Predictive maintenance and self-diagnosing equipment can also work wonders for reliability. Many newer technologies have built-in diagnostic mechanisms that will alert operators when electrical contacts are wearing down to the point where replacement is necessary. Companies can take advantage of wide-ranging predictive maintenance solutions to remotely monitor their equipment on a round-the-clock basis.

Capable of dramatically expanding customization options, supporting environmental sustainability, and improving overall production efficiency, a flexible packaging strategy is the gold standard for many companies. The value of this strategy is greatest, however, when packagers invest in the right machinery that can improve seal integrity, changeover speed, ease of use, cleanability, and reliability. Choosing the right automation supplier can ensure that a transition into flexible packaging serves to reduce complexity and boost efficiency, rather than vice-versa.

About the Author(s)

You May Also Like