Shrink Film Sustainability: Problems and Solutions

These four solutions and three takeaways provide guidance in responding to the removal of PETG label materials from #1 PET recycling streams in California.

January 24, 2024

At a Glance

- Truly recyclable materials need to be successfully handled by the majority of MRFs and reclaimers

- If you are making changes today to meet regulatory requirements, look for solutions that will still be viable in 10 years

- Do not expect many consumers to actively participate in your waste diversion efforts

Once California excluded polyester glycol (PETG or PET-G) from being called or labeled resin-identification code (RIC) 1 aka PET #1, the industry quickly began to look for alternatives. These included the use of PET-C (semi-crystalline polyester), elimination of labels entirely, and the development of processes that can reduce contamination in the PET bottle recycling stream.

Of course, some companies have simply continued to use PETG in the hope that California regulatory authorities will neither find out nor decide to prosecute.

Here's what the array of options looks like.

1. Zip-off sleeves.

About a month ago, I responded to a LinkedIn post that expounded on the virtues of innovative shrink-wrap labels that consumers can remove post-use by tearing off a vertical strip, tossing the label in the trash (!), and putting the HDPE, PET, or PP bottle into the recycling bin.

My response, which drew a rather amazing 28,000 readers, was that asking consumers to solve problems created by consumer-packaged goods (CPG) companies and their converters would not move the recycling needle here in the US. I pointed out that P&G had already tried this approach, with limited success. (In fact, P&G packaging engineers who prefer to remain anonymous contacted me and confirmed my conclusion.)

A few people wrote to tell me that Japanese, Koreans, and Europeans remove these labels. My response was that social factors in these areas do not apply here. We do not have the cultural and emotional pressures to act collectively, as found in Asia; nor do we have the respect for authority that is apparent in places like Germany or Austria.

2. Washable inks.

A few companies are promoting so-called washable inks. But problems can occur when these inks are used on PET-C labels and do not actually wash off, thus contaminating high grade PET bottle flakes and making them unrecyclable. Proprietary research conducted in a post-consumer materials recycling facility (MRF) environment using products purchased in retail stores indicates that popular washable inks do not fully wash off, contaminating the rPET stream.

In fact, once tested in the real world rather than lab conditions, these inks and thus the labels to which they are applied, did not meet The Association of Plastic Recyclers (APR) standards.

Also, even if wash-off inks work as advertised, labels that have inherently lower IV (Intrinsic Viscosity, in this case molecular weight) cannot be mixed with PET bottles without degrading rPET quality.

Labels and bottles thus must be separated for each to be recycled, a process that is both expensive and rarely done by either MRFs or reclaimers.

3. Magnetizable coatings.

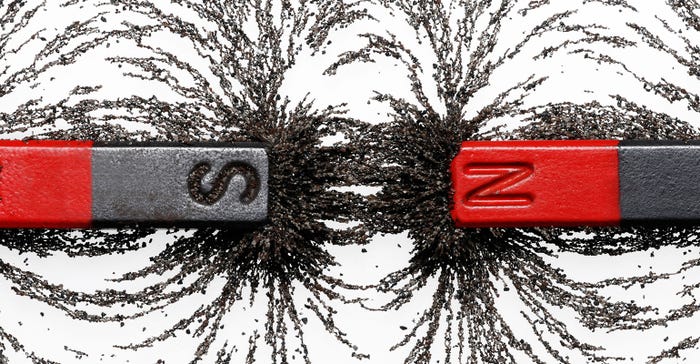

Another solution has been developed by a company called Magnomer, about which I wrote in PlasticsToday in December 2021. Since then, their business model has adjusted to accommodate the new rules and regulations introduced in California. Their solution is elegant and simple: They produce a magnetizable coating that can be applied to any label. After being baled at the MRF and sent to a reclaimer, both the bottle and label are flaked, and the resulting stream is passed under magnets which remove the metallized label flakes.

This process meets APR requirements. In fact, the separated label flakes can be recycled into low-grade PET applications, and the company has found a buyer who will do so. (Note: Magnomer is part of the SPRING mentorship program. SPRING has no financial stake in the company, nor has it received any compensation for work done on its behalf.)

4. Label-less bottles.

Finally, we’re seeing label-less bottles hit the market. These are great for multipacks, where the outer wrap acts as both a merchandising and informational label for all the pack’s bottles. However, it is probably not an acceptable marketing solution for most products sold individually on store shelves. The companies with enough brand identity and power to have their label-less packages remain relevant on-shelf are few and far between. (Think Coke, with its iconic de-embossed lettering and swirls, plus enormous shelf presence and consumer recognition.)

Here are three takeaways from this review:

Think downstream. Products and processes that cannot be successfully handled by the majority of MRFs and reclaimers do not lead to truly recyclable materials. APR approval is a first step, but solutions still need to be vetted in the marketplace.

Think long term. If you are making changes today to meet regulatory requirements, look for solutions that will still be viable 10 years from now. These should be considered as strategic, rather than tactical, opportunities.

Think convenience. Do not expect many consumers to actively participate in your waste diversion efforts. The typical adult or child will not do anything more than put a product in either the trash or recycling bin. Make sure that the proper post-use handling of your packaging by consumers is easy for them to understand and perform.

About the Author(s)

You May Also Like