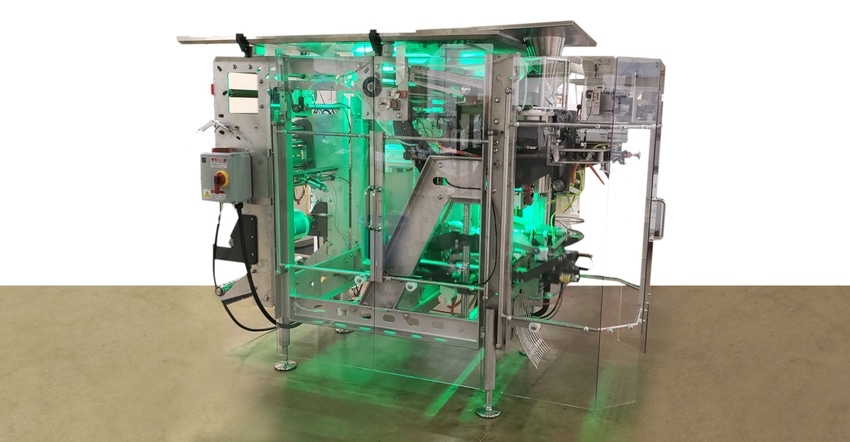

VFFS Bagger Boasts Intelligent, Sanitary Design for Food Packaging

The machine is intuitive to operate, easy to change over, and designed with a variety of hygienic features.

Food packagers that use flexible packaging will appreciate the intelligent, hygienic design and intuitive operation of the new Hayssen ISB vertical-form-fill-seal (VFFS) bagger from BW Flexible Systems, a Barry-Wehmiller Packaging Co. Packaging applications include frozen/individually quick-frozen (IQF) food, fresh produce, and cheese.

The entire machine, including its human-machine interface (HMI), can be washed down. In addition, the bagger has an IP66 weather-proofing rating and a NEMA 4X rating for enclosures. Hygienic features include the bagger’s open-channel frame design, with sloped surfaces and a maximum of 1 square inch of surface-to-surface contact between components.

Standoffs and flanged fasteners eliminate hardware like washers, and the bagger’s film rollers can be fully removed without tools. Friction belts are used on the machine instead of vacuum belts, which pose the risk of pathogen growth.

The bagger can self-diagnose issues in real time and automatically calculates program values for optimal performance. Changeovers are toolless except for the sealing jaws. The machine’s unwind and film path has been designed for immediate film-tracking adjustments, and the bagger automatically maintains film tension using a laser measuring system.

BW Flexible Systems will be exhibiting this new product at Pack Expo Las Vegas 2021 (Las Vegas Convention Center, September 27-29), Booth C-1800.

About the Author(s)

You May Also Like